Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- CAS No.

- 7440-22-4

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Benefits

- Coating and patterning by inkjet or slot-die printing

- Low temperature process

- Printed on polymers, glasses, metals and active materials

- No solid or liquid waste

- Environmentally friendly

- Cost-efficient solution

Applications & Uses

- Markets

- Applications

- Application Method

- Cure Method

- Applications of the Ink

- EMI shielding

- Radio frequency (RF)

- Wireless components

- Memory

- Sensors

- Other sensitive devices

Properties

- Physical Form

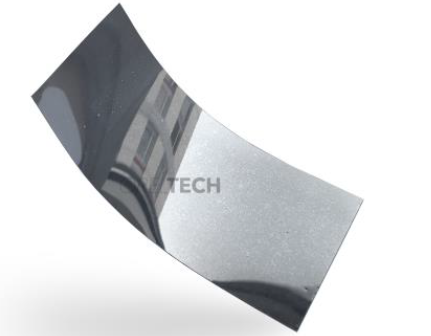

- Appearance

- Clear Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Conductivity (bulk, Cured Film) | 30 – 55 | % | — |

| Coverage (Ink) | 2500 | cm²/gr | — |

| Layer Thickness (Cured Film) | 200 - 1500 | nm | — |

| Resistivity (Cured Film) | 5.6 - 2.9 | μΩ·cm | — |

| Sheet resistance (Cured Film) | 0.1 - 3 | Ω/sq | — |

| Viscosity (Ink) | 10 - 60 | cP | — |

Technical Details & Test Data

- OrelTech silver electrode on PET

- OrelTech silver electrode on paper

- Curing Conditions

- Curing time: 1-5 minutes.

- Curing apparatus: Cold plasma instrument with a low pressure chamber.

- Curing temperature: Temperature in the plasma chamber does not exceed 70 ⁰C. No additional heating is needed. That temperature can be lowered to room temperature using a temperature-controlled plasma chamber.

Packaging & Availability

- Country Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months

- Directions for Use and Storage

- Storage: Inks can be stored in closed containers for up to 12 month in dry, dark conditions.

- Clean-up: Materials can be cleaned up using alcohols and ketones, preferably isopropanol.

- Pre-treatment: In some cases, to ensure better wettability and/or adhesion, the substrate material must be pre-treated prior to ink application.