Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- CAS No.

- 7440-22-4

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Benefits

- Coating and patterning by inkjet, slot-die or aerosol printing

- Low temperature process

- Printed on polymers, glasses and active materials

- Very flexible

- No solid or liquid waste

- Environmentally friendly

- Cost-efficient solution

Applications & Uses

- Applications

- Application Method

- Cure Method

- Applications of the Ink

- OLEDs

- Solar cells

- Displays

- Touchscreens

- Transistors

- Other sensitive devices

- Applications Of Cured Film

- OLEDs

- Touch Screens

- Photovoltaics

- ITO Replacement

Properties

- Physical Form

- Appearance

- Clear Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Conductivity (bulk, Cured Film) | max. 50 | % | — |

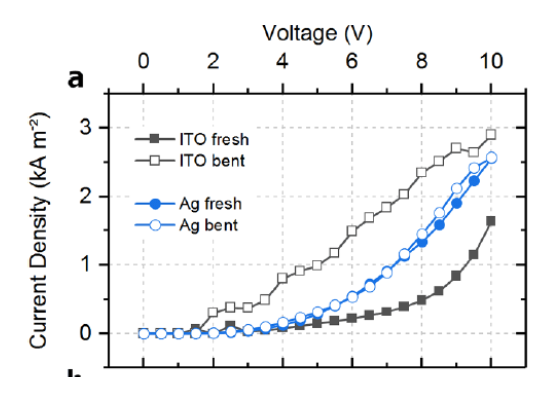

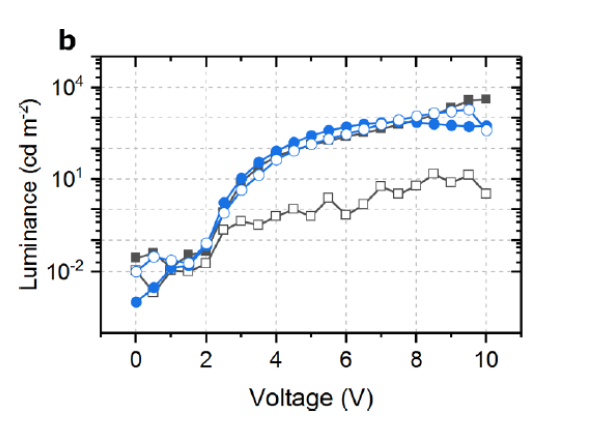

| Flexible (Cured Film) | min. 50,000 | cycles | — |

| Transmission (Cured Film) | max. 85 | % | — |

| Viscosity (Ink) | 10 - 60 | cP | — |

Technical Details & Test Data

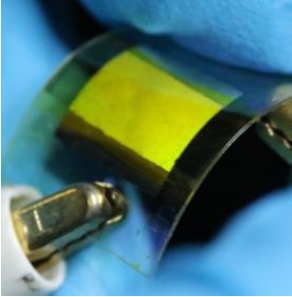

- Flexible OLED device based on OTech T

- OREL Tech publications 1

- OREL Tech publications 2

- Curing Conditions

- Curing time: 1-5 minutes.

- Curing apparatus: Cold plasma instrument with a low pressure chamber.

- Curing temperature: Temperature in the plasma chamber does not exceed 70 ⁰C. No additional heating is needed. That temperature can be lowered to room temperature using a temperature-controlled plasma chamber.

Packaging & Availability

- Country Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months

- Directions for Use and Storage

- Storage: Inks can be stored in closed containers for up to 12 month in dry, dark conditions.

- Clean-up: Materials can be cleaned up using alcohols and ketones, preferably isopropanol.

- Pre-treatment: In some cases, to ensure better wettability and/or adhesion, the substrate material must be pre-treated prior to ink application.