Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

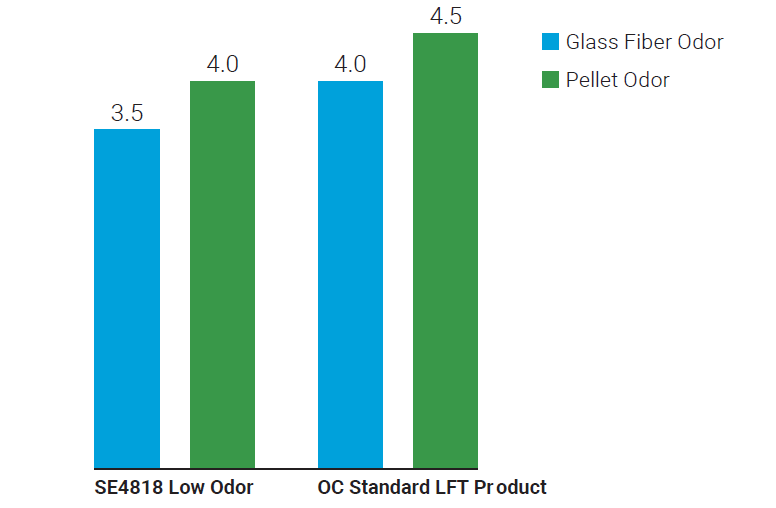

- Low Odor Verified: SE4818 Low Odor has been proven to meet low odor requirements per OEM test standards for automotive interior composite parts. Test methods include: VDA270 German Association of the Automotive Industry, PV3900 Volkswagen SAE standards and testing and the Geely Low Odor test method Q/JLY J1770528D.

- Excellent Processing – low fuzz: No catenary and low fuzz promotes superior processing, enabling higher efficiencies and lower manufacturing costs with less downtime for clean-up.

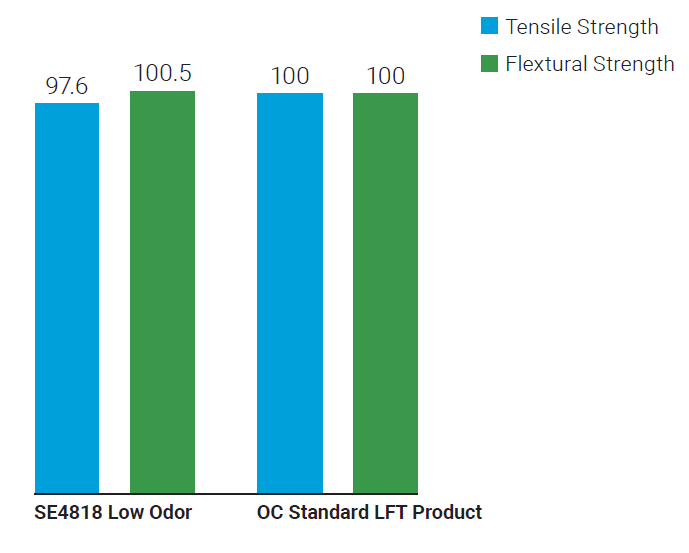

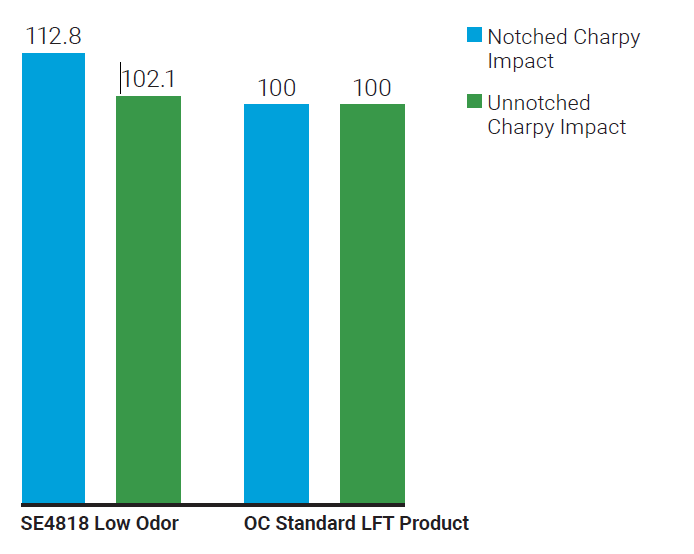

- Superior Composite Strength: Compared to other reinforcements on the market, SE4818 Low Odor offers superior composite tensile , flexural and Impact performance. Providing maximum part strength and long part service life.

- Excellent Impregnation & Dispersion: High Quality Dispersion within the pellet and final mold, creating excellent surface appearance and part strength.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Composites End Use

- Applications

SE4818 Low Odor is ideal for interior automotive composite parts where low odor is required. This material can also be used in a variety of other applications.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Characteristics

Strength

Impact

Odor test

Odor test SE4818 Low Odor is proven to have less odor compared to standard LFT products.

SE4818 Low Odor is proven to have less odor compared to standard LFT products.Data Resources

- Odor: PV3900, tested by Intertek.

- Mechanical properties: 50% GF, ISO test bars prepared by injection molding. Tested by TP lab ATC. All data normalized to 100.

Packaging & Availability

- Packing and Labelling

Packaging and Palletization (Standard Reference)

Pallet Dimensions

Packaging Pallet Height (cm) Pallet Length (cm) Pallet Width (cm) Pallet Weight Net, Kg) Packages per Pallet Number of Layers

No Tube ~125 115 115 ~1200 64 4 No Tube ~97 115 115 ~900 48 3 Thicker Tube ~100 115 115 ~900 48 3 Package Dimensions

Package Height (cm) Package Outside Diameter (cm) Package Inside Diameter (cm)

Package Weight (Kg, Weight% In Pallet)

<28.0 <30.0 >16.2 (No tube) ~16.2 (Thick tube) 16~20 (70%) 10~16 (25%) 5~10 Each individual package is labeled with information including product name, tex/yield, producing plant and production date.

- Availability

SE4818 Low Odor is available in Asia Pacific.

Tex Filament Diameter (µ) Loss on Ignition (%) Moisture (% Max) Manufacturing Region 2400 17 0.35 <0.05 Asia Pacific

Storage & Handling

- Storage

Unless otherwise specified, it is recommended to store glass fiber products in a cool, dry area. The glass fiber products must remain in their original packaging material until the point of usage. The product should be stored in the workshop in its original packaging for 48 hours prior to its utilization, to allow it to reach the workshop temperature condition and prevent condensation, especially during the cold season. The packaging is not waterproof. Be sure to protect the product from the weather and other sources of water. When stored properly, there is no known shelf life to the product, but retesting is advised after three years from the initial production date to insure optimum performance.