Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- 9009-90 Meets Your Needs

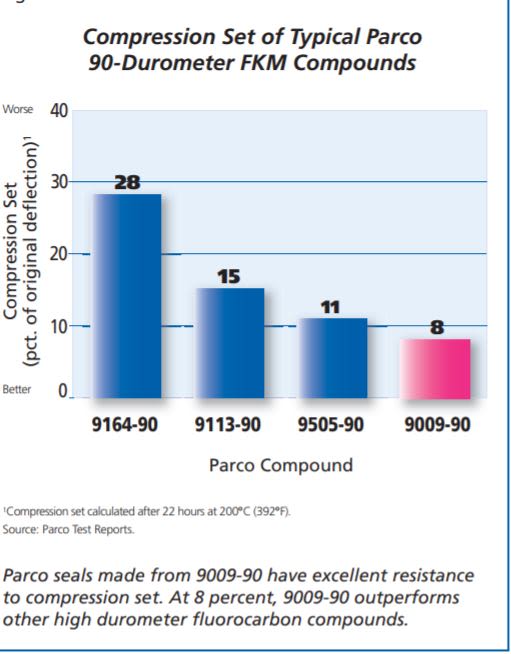

Excellent Resistance to Compression Set When installed, seals must resist taking a set from compression. When a seal takes a set, it no longer exerts force on the mating surfaces, resulting in leakage. A compound with low compression set, like our 90-durometer fluorocarbon compound 9009-90, better maintains its elastomeric properties and original thickness, preserving seal integrity. Seals made form Parco’s 9009-90 compound provide excellent resistance to compression set at higher temperatures . After testing 9009-90 for 22 hours at 392°F, it had a compression set of only 8 percent.

Outstanding Resistance to Fuel Parco’s 9009-90 seals offer outstanding performance in fuel, including gasoline and diesel. Exposure to such fluids can cause seals to swell significantly. Our 9009-90 seals had volume swell of only 1 percent after 70 hours at 73°F in Refence Fuel C.

Exceeds AMS 7259 Seals made from our 9009-90 compound exceed the requirements of Aerospace Material Specification (AMS) 7259 (see test report on reverse side). Parco supplies seals to 28 military and aerospace specifications. We are also one of only a few manufacturers approved to supply Qualified Products List (QPL) rubber seals. Our quality system is certified to ISO 9001, ISO/TS 16949, AC7115, and AS9100. So when you specify 9009-90, rest assured that you’ve made the right choice

Applications & Uses

- Applications

- Cure Method

- Plastics & Elastomers End Uses

- Chemical Resistance

USE WITH DO NOT USE WITH - Carbon Tetrachloride

- Diester Synthetic Lubricants

- Gasoline

- Hot Air

- Toluene

- Acetone

- Amines

- Ethyl Acetate

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Hardness | 89.0 | Shore A | D2240 |

| Tensile Strength | 2437.0 | psi | D412 |

| Ultimate Elongation (pct) | 139.0 | — | D412 |

| Modulus (100 pct, Elongation) | 1790.0 | psi | D412 |

| Compression Set 22 hours (200°C, 392°F ) Pct of Original Deflection | 7.0 | — | D395 |

| Heat Aging 70 hours (250°C, 482°F) Hardness Change, pts. | 1.0 | Shore A | D573 |

| Heat Aging 70 hours (250°C, 482°F) Tensile Strength Change, pct. | -5.0 | — | D573 |

| Heat Aging 70 hours (250°C, 482°F) Ultimate Elongation Change, pct. | -3.0 | — | D573 |

| Fluid Aging, Fuel C 70 hours (23°C, 73°F) Hardness Change, pts. | -3.0 | Shore A | D471 |

| Fluid Aging, Fuel C 70 hours (23°C, 73°F) Tensile Strength Change, pct. | -1.0 | — | D471 |

| Fluid Aging, Fuel C 70 hours (23°C, 73°F) Ultimate Elongation Change, pct. | 7.0 | — | D471 |

| Fluid Aging, Fuel C 70 hours (23°C, 73°F) Volume Change, pct. | 2.0 | — | D471 |

| Low Temperature Flexibility TR-10°C (°F) | -18(0) | °C(°F) | D1329 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

- Technical Details

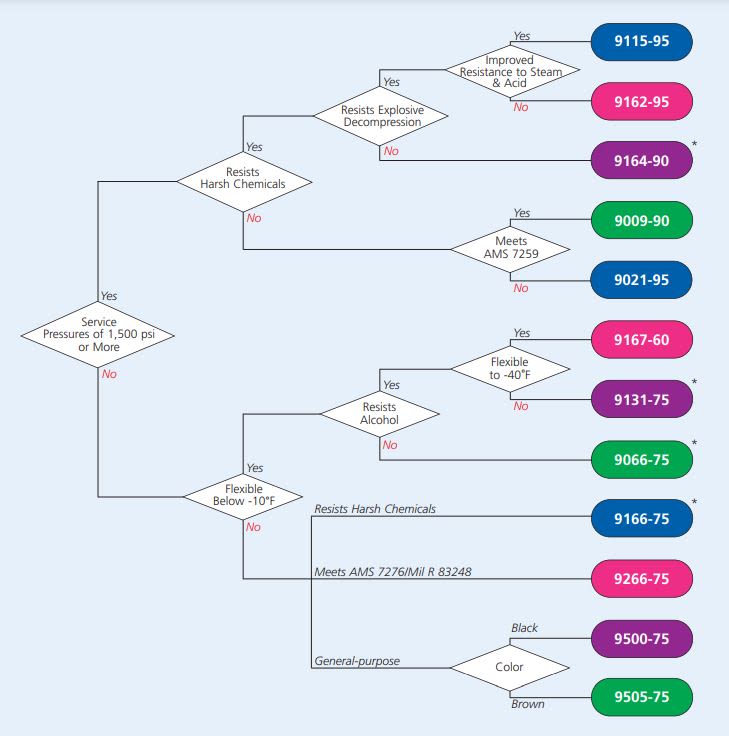

Parco’s fluorocarbon seals provide excellent resistance to a wide range of chemicals and temperatures. This selection diagram will help you choose among Parco’s popular fluorocarbon compounds. Parco also offers more than 40 fluorocarbon compounds not shown in this diagram. If we don’t have a compound for your application, we can develop one for you.