Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Nitrile Compound Characteristics

A brief review of the characteristics of nitrile compounds can remove much of the guesswork from the selection process. Consider the following five factors when selecting a nitrile seal compound:

Oil Resistance

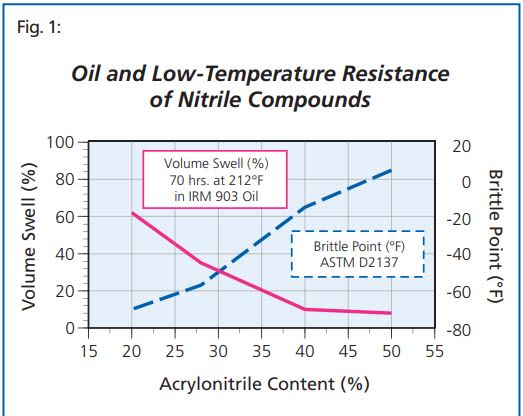

The relative proportions of acrylonitrile and butadiene determine the oil resistance and lowtemperature performance of nitrile seals. High acrylonitrile content improves oil resistance at the expense of low-temperature performance (Figure 1). The acrylonitrile content of commercial nitriles typically ranges from 20 to 50%.

Oil resistance improves (as indicated by the decrease in volume swell) with increasing acrylonitrile content. At the same time, however, the brittle point rises, reflecting a loss in low-temperature performance.

Compression Set ResistanceNitrile compounds incorporate either sulfur or peroxide curative. Sulfur-cured seals, such as those made from Parco’s most popular nitrile compound 4200-70, are generally more economical as they require shorter molding times. Sulfur curing produces compounds with good resistance to compression set and extrusion resistance and ultimate elongation. Sulfur-cured compounds are often used to mold rubber-to-metal bonded parts. By contrast, peroxide-cured compounds generally have better compression set resistance, higher extrusion resistance and lower elongation. They also tend to have better heat resistance but may be more expensive due to the longer molding times required.

Low-Temperature Resistance

Plasticizers typically improve low-temperature flexibility and resistance to volume swell. However, nitrile seals containing ester plasticizers frequently cause surface crazing when used with some plastics. Parco manufactures several types of nitrile seals containing non-ester plasticizers specifically developed for use with plastics.

Mechanical Properties

All Parco nitrile compounds contain filler materials that reinforce the compound and generally improve the mechanical properties of the seal. Carbon black, the most commonly used filler, improves the tensile strength, extrusion resistance, and abrasion resistance of the compound. When non-black seals are required for identification, mineral fillers are used instead of carbon black. Compounds with carbon black fillers generally have better compression set resistance and resilience than compounds with mineral fillers.

Price

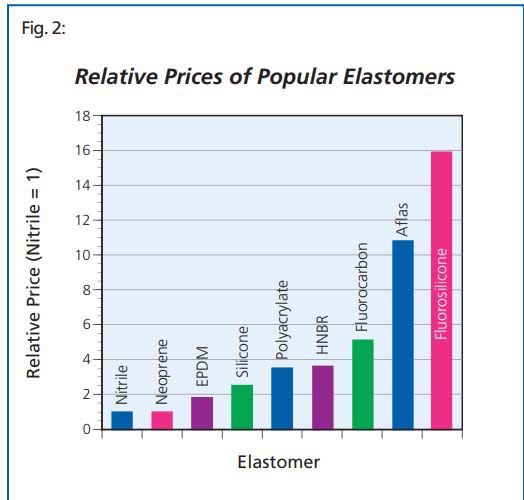

Nitrile seals are the most economical of the popular seals available and, due to their outstanding service capabilities, offer excellent value (Figure 2). Of popular seal materials, only neoprene can routinely match the low price offered by nitrile.

This chart shows the prices of Parco O-rings made of the most popular compound of each elastomer and is intended to provide a rough estimate of relative price. These prices are based on a comparison of 30 popular sizes of O-rings for each compound.- Rely on Parco for Nitrile Seals

Founded in 1941, Parco was the first manufacturer to specialize in O-rings, still one of our primary products. Today, Parco has two modern facilities manufacturing O-rings, custommolded elastomeric seals, rubber-to-metal bonded parts, and machined metal parts. Parco sells to many Fortune 500 companies, who demand world-class quality. To maintain the highest quality we make our own molds, develop and mix our own compounds, and mold our parts in computer-controlled presses. Our quality management system is certified to international standards ISO 9001 and ISO/TS 16949 and aerospace standards AS9100 and AC7115

- Key Features

Parco’s nitrile seals are an excellent choice for various applications. Key features include the following:

• Excellent resistance to various chemicals: Parco nitrile seals resist a broad range of industrial, automotive, and aircraft fluids.

• Wide range of service temperatures: Parco nitrile seals are suitable for applications from -65° to +285°F, depending on the compound.

• UL-listed: Certain Parco nitrile seals are UL-listed for gasoline, kerosene, LP gas, diesel fuels, and fire extinguishers.

• MIL SPEC conforming: Parco offers nitrile seals to meet demanding military and aerospace specifications.

• Unsurpassed economy: Nitrile is the most economical high-performance seal material available.- Product Highlight

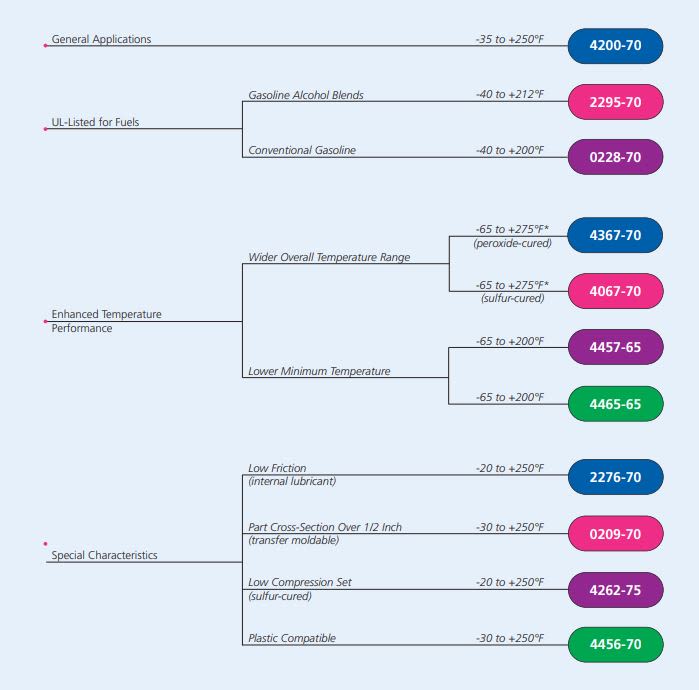

Nitrile compounds are the most widely used industrial seal materials. Parco’s nitrile seals offer excellent service in diverse fluids, including hydrocarbon fuels and fluids, solvents, water, and water-based solutions. Those seals have a long history of reliable service from -65 to 250°F at pressures up to 1,500 psi. Because of the excellent economy of nitrile seals, follow Parco’s general rule: consider nitrile seals first. Nitrile compounds are copolymers of acrylonitrile and butadiene. Acrylonitrile provides resistance to petroleum-based fluids such as oils and fuels, while butadiene contributes to low-temperature flexibility. Different nitrile compounds are formulated by adjusting acrylonitrile levels to achieve the desired balance of petroleum-based fluid resistance and flexibility at the anticipated service temperature. Standard nitrile is also known as Buna N Rubber or by the ASTM D1418 designation NBR. Parco offers more than 100 nitrile compounds tailored to a broad range of operating conditions. Acrylonitrile content, curing system, and type and quantity of plasticizers are a few of the compounding factors that can be varied to match the seal material to the end-user’s requirements. Parco also produces special types of nitriles for more demanding applications. Hydrogenated nitrile, designated HNBR, is used with automotive lubricants and sour crude oil containing aminebased corrosion inhibitors. HNBR is also used when a seal is exposed to ozone and higher temperatures. Carboxylated nitrile, designated XNBR, provides improved abrasion resistance and superior extrusion resistance at high pressures. If you are unfamiliar with the different types of elastomeric seal materials currently in use, consult Parco’s Elastomer Selection Guide before reading this guide. There you will find guidelines to help you select the best elastomer for your application. When you have determined that a nitrile compound may be appropriate for your application, use this guide to narrow your choice. Contact a Parco customer service representative to to obtain additional product information about specific nitrile compounds.

Applications & Uses

- Applications

- Cure Method

- Plastics & Elastomers End Uses

- Used In

Nitrile O-rings are used in a broad range of industrial, automotive, and aircraft fluids at temperatures between -65 and 250°F. More than 50 percent of sealing needs can be met using nitrile seals.

Properties

- Chemical Resistance

- Color

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Hardness | 73.0 | Shore A | D2240 |

| Tensile Strength | 1974.0 | psi | D412 |

| Ultimate Elongation (pct) | 361.0 | — | D412 |

| Modulus (100 pct, Elongation, pct) | 814.0 | psi | D412 |

| Compression Set Solid 22 hours (100°C, 212°F ) Pct of Original Deflection | max. 16 | — | D395 |

| Heat Aging 70 hours (100°C, 212°F) Hardness Change, pts. | 6.0 | Shore A | D573 |

| Heat Aging 70 hours (100°C, 212°F) Tensile Strength Change, pct. | 6.0 | — | D573 |

| Heat Aging 70 hours (100°C, 212°F) Ultimate Elongation Change, pct. | max. -26 | — | D573 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Hardness Change, pts. | -16.0 | Shore A | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Tensile Strength Change, pct. | -35.0 | — | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Ultimate Elongation Change, pct. | -42.0 | — | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Volume Change, pct. | 25.0 | — | D471 |

| Low Temperature Flexibility TR-10 | -23(-10) | °C(°F) | D1329 |

| Low Temperature Flexibility Glass Transition (Midpoint) | -42(-43) | °C(°F) | D1329 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

*High temperature limit is based on requirements in MIL-P-25732 and AMS-P-83461