Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

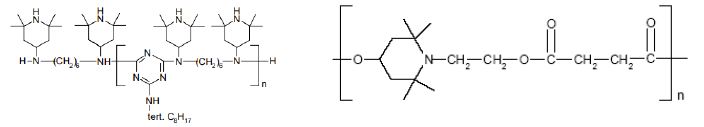

- Chemical Structure

Features & Benefits

- Key Attributes

PUREsorb 783 is a versatile light stabilizer for thin and thick sections and delivers excellent cost and performance benefits. PUREsorb 783 can be used at levels not possible with other conventional stabilizers for applications requiring indirect food approvals. The synergism between the two high molecular weight HALS components of PUREsorb 783 helps to provide an efficient stabilization to the polymer against degradation through UV radiation and long-term heat exposure.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Product Applications

Application of PUREsorb 783 include polyolefins (PP, PE), olefin copolymers such as EVA as well as blends of polypropylene with elastomers and PA.

Guidelines for Use-

UV Stabilization of: Usage Thick sections HDPE, LLDPE, LDPE & PP 0.1 – 0.8% Films LLDPE & PP 0.1 – 1.0% Tapes PP & HDPE 0.1 – 0.8% Fibers PP 0.1 – 1.0%

Properties

- Color

- Physical Form

- Appearance

- White to slightly yellow pastilles

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Melting Range | 55 - 140 | °C | — |

| Flash Point | 192.0 | °C | — |

| Bulk Density | 514.0 | g/l | — |

Storage & Handling

- Product Handling

In accordance with good industrial practice, handle with care and avoid unnecessary personal contact. Avoid continuous or repetitive breathing of dust. Use only with adequate ventilation. Avoid dust formation and ignition sources.

- Product Storage

This product may be stored in a sealed container. Containers should be kept tightly closed when not in use and stored in a cool, dry place.