Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Wear and Friction Solutions High Temperature Materials

Design engineer look to replace metal parts and components with thermoplastics whenever possible. Not only can they be produced more cost-effectively, they offer greater design flexibility, weigh less and resist corrosion. The availability of high temperature resins like PEEK, PPS, PPA and PEI can stretch the use of thermoplastic even further.

If you can’t stand the heat… internally lubricated compounds: While auto under-the-hood and industrial machinery might be the first to come to mind, high temperature application are not always driven by hot operating environment. Some application that may never see elevated use temperatures have to survive a hot manufacturing environment (lead-free solder, paint ovens). High temperature generally feature good chemical resistance as well.

Internally lubricated compounds:

The addition of an internal lubricant to a thermoplastic material can improve the wear resistance and can reduce the coefficient of friction in plastic parts. Traditional lubricants like PTFE and PTFE/Si blends are common. Compounds made with high temperature resins can provide wear performance comparable with externally lubricated metal parts.

- Product Features

- FM: 11.1GPa

- HDT:257°C

- Chemical resistance

- Low wear and COF

- UL94-V0@0.75 mm,

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Impact Properties

- Injection Molding

- Flame Characteristics

- Note

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

| Value | Units | Test Method / Conditions | |

| Tensile Stress (Break, Type I, 5 mm/min) ¹¹ | 124 | MPa | ASTM D638 |

| Tensile Stress (Break) ¹¹ | 145 | MPa | ASTM D638 |

| Tensile Stress (Break) ¹¹ | 124 | MPa | ISO 527 |

| Tensile Strain (Break, Type I, 5 mm/min) ¹¹ | 1.3 | % | ASTM D638 |

| Tensile Strain (Break) ¹¹ | 1.7 | % | ASTM D638 |

| Tensile Strain (Break) ¹¹ | 1.4 | % | ISO 527 |

| Tensile Modulus (at 50 mm/min) ¹¹ | 12600 | MPa | ASTM D638 |

| Flexural Stress (Break, 1.3 mm/min, 50 mm span) ¹¹ | 178 | MPa | ASTM D790 |

| Flexural Stress ¹¹ | 180 | MPa | ISO 178 |

| Flexural Stress ¹¹ | 200 | MPa | ASTM D790 |

| Flexural Stress ¹¹ | 197 | MPa | ISO 178 |

| Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ | 11600 | MPa | ASTM D790 |

| Flexural Modulus ¹¹ | 11030 | MPa | ASTM D790 |

| Flexural Modulus ¹¹ | 10950 | MPa | ISO 178 |

| Tensile Stress (Break, 5 mm/min) ¹¹ | 121 | MPa | ISO 527 |

| Tensile Strain (Break, 5 mm/min) ¹¹ | 1.3 | % | ISO 527 |

| Tensile Modulus (at 1 mm/min) ¹¹ | 11500 | MPa | ISO 527 |

| Flexural Modulus (at 2 mm/min) ¹¹ | 11050 | MPa | ISO 178 |

| Value | Units | Test Method / Conditions | |

| Density ¹¹ | 1.7 | g/cm³ | ASTM D792 |

| Density ¹¹ | 1.7 | g/cm³ | ISO 1183 |

| Moisture Absorption (at 23°C, 50% RH, 24hrs) ¹¹ | 0.01 | % | ASTM D570 |

| Mold Shrinkage (flow, 24 hrs) ᵍ ¹¹ | 0.1 - 0.2 | % | ASTM D955 |

| Mold Shrinkage (flow, 24 hrs) ᵍ ¹¹ | 0.13 - 0.18 | % | ISO 294 |

| Mold Shrinkage (xflow, 24 hrs) ᵍ ¹¹ | 0.6 - 0.8 | % | ASTM D955 |

| Mold Shrinkage (xflow, 24 hrs) ᵍ ¹¹ | 0.3 - 0.5 | % | ASTM D955 |

| Mold Shrinkage (xflow, 24 hrs) ᵍ ¹¹ | 0.3 - 0.48 | % | ISO 294 |

| Wear Factor Washer ¹¹ | 33 | 10^-10 in^5-min/ft-lb-hr | ASTM D3702 Modified: Manual |

| Wear Factor Washer ¹¹ | 52 | 10^-10 in^5-min/ft-lb-hr | ASTM D3702 Modified: Manual |

| Dynamic COF ¹¹ | 0.44 | — | ASTM D3702 Modified: Manual |

| Static COF ¹¹ | 0.35 | — | ASTM D3702 Modified: Manual |

| Moisture Absorption (at 23°C, 50% RH) ¹¹ | 0.04 | % | ISO 62 |

| Moisture Absorption (at 23°C, 50% RH) ¹¹ | 0.01 | % | ISO 62 |

| Wear Factor Ring ¹¹ | 7 - 8 | 10^-10 in^5-min/ft-lb-hr | ASTM D3702 Modified: Manual |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ | 266 | °C | ASTM D648 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, flow) ¹¹ | 0.0000236 | 1/°C | ISO 11359-2 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, flow) ¹¹ | 0.0000234 - 0.00005003 | 1/°C | ASTM E831 |

| Heat Deflection Temperature (at 0.45 MPa, 3.2 mm, Unannealed) ¹¹ | 278 | °C | ASTM D648 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, xflow) ¹¹ | 0.0000486 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, xflow) ¹¹ | 0.0000501 | 1/°C | ISO 11359-2 |

| Coefficient of Thermal Expansion (at -30°C to 30°C, flow) ¹¹ | 0.000025 | 1/°C | ASTM D696 |

| Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 266 | °C | ISO 75/Af |

| Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 257 | °C | ISO 75/Af |

| Coefficient of Thermal Expansion (at -30°C to 30°C, xflow) ¹¹ | 0.000034 | 1/°C | ASTM D696 |

| Relative Temperature Index (Electrical) ᵖ ¹¹ | 200 | °C | UL 746B |

| Relative Temperature Index (Mechanical with impact) ᵖ ¹¹ | 130 | °C | UL 746B |

| Relative Temperature Index (Mechanical without impact) ᵖ ¹¹ | 130 | °C | UL 746B |

| Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 278 | °C | ISO 75/Bf |

| Value | Units | Test Method / Conditions | |

| Comparative Tracking Index (UL, PLC) ᵖ ¹¹ | 4 | PLC Code | UL 746A |

| Hot Wire Ignition (PLC 0) ᵖ ¹¹ | min. 1.5 | mm | UL 746A |

| High Ampere Arc Ignition (PLC 0) ᵖ ¹¹ | min. 1.5 | mm | UL 746A |

| Hot Wire Ignition (PLC 3) ᵖ ¹¹ | min. 0.75 | mm | UL 746A |

| High Voltage Arc Track Rate (PLC) ᵖ ¹¹ | 4 | PLC Code | UL 746A |

| Arc Resistance (Tungsten, PLC) ¹¹ | 7 | PLC Code | ASTM D495 |

| High Ampere Arc Ignition (PLC 2) ᵖ ¹¹ | min. 0.75 | mm | UL 746A |

| Value | Units | Test Method / Conditions | |

| Izod Impact (Unnotched, at 23°C) ¹¹ | 550 | J/m | ASTM D4812 |

| Izod Impact (Unnotched, at 23°C) ¹¹ | 416 | J/m | ASTM D4812 |

| Izod Impact (Notched, at 23°C) ¹¹ | 60 | J/m | ASTM D256 |

| Izod Impact (Notched, at 23°C) ¹¹ | 85 | J/m | ASTM D256 |

| Instrumented Dart Impact Energy (Peak, at 23°C) ¹¹ | 3 | J | ASTM D3763 |

| Multi-Axial Impact ¹¹ | 1 | J | ISO 6603 |

| Multi-Axial Impact ¹¹ | 2 | J | ISO 6603 |

| Instrumented Dart Impact Total Energy (at 23°C) ¹¹ | 11 | J | ASTM D3763 |

| Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ | 25 | kJ/m² | ISO 180/1U |

| Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ | 5 | kJ/m² | ISO 180/1A |

| Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ | 9 | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Drying Temperature ⁷ | 120 - 150 | °C | — |

| Drying Time ⁷ | 4 | Hrs | — |

| Melt Temperature ⁷ | 315 - 320 | °C | — |

| Front - Zone 3 Temperature ⁷ | 330 - 345 | °C | — |

| Middle - Zone 2 Temperature ⁷ | 320 - 330 | °C | — |

| Rear - Zone 1 Temperature ⁷ | 305 - 315 | °C | — |

| Mold Temperature ⁷ | 140 - 165 | °C | — |

| Back Pressure ⁷ | 0.2 - 0.3 | MPa | — |

| Screw Speed ⁷ | 30 - 60 | rpm | — |

| Value | Units | Test Method / Conditions | |

| UL Recognized (94V-0 Flame Class Rating) ᵖ | min. 0.75 | mm | UL 94 |

| Glow Wire Ignitability Temperature (at 0.75 mm) ᵖ | 800 | °C | IEC 60695-2-13 |

| Glow Wire Flammability Index (at 0.75 mm) ᵖ | 960 | °C | IEC 60695-2-12 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- LNP™ Compounds Wear and Friction Solutions High Temperature Materials

While auto under-the-hood and industrial machinery might be the first to come to mind, high temperature application are not always driven by hot operating environment. Some application that may never see elevated use temperatures have to survive a hot manufacturing environment (lead-free solder, paint ovens). High temperature generally feature good chemical resistance as well.

The addition of an internal lubricant to a thermoplastic material can improve the wear resistance and can reduce the coefficient of friction in plastic parts. Traditional lubricants like PTFE and PTFE/Si blends are common. Compounds made with high temperature resins can provide wear performance comparable with externally lubricated metal parts.

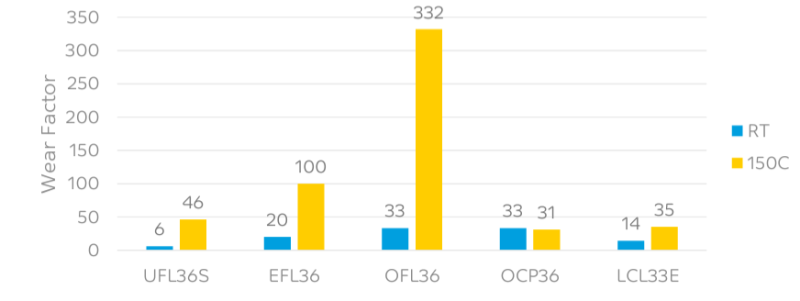

Wear at Elevated Temperatures

Packaging & Availability

- Regional Availability