Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Compound for Mechatronics

LUBRICOMP RAL23 is an Aramid filled, PTFE lubricated PA66 compound developed for gear, bearing- and sliderapplications as used for mechatronics engineering. This grade can offer a plastic-plastic, lowest slip-stick solution with increased reliability and improved transmission efficiency, whilst helping to improve the noise ergonomics In abrasive wear modes.

Effects

- Wear and Friction

- Typical Industry Requirements

- Transmission efficiency

- No noise

- Good tribological performance when combined with glass fiber reinforced systems, used for structural performance

- Avoidance grease at sub- zero temperatures

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

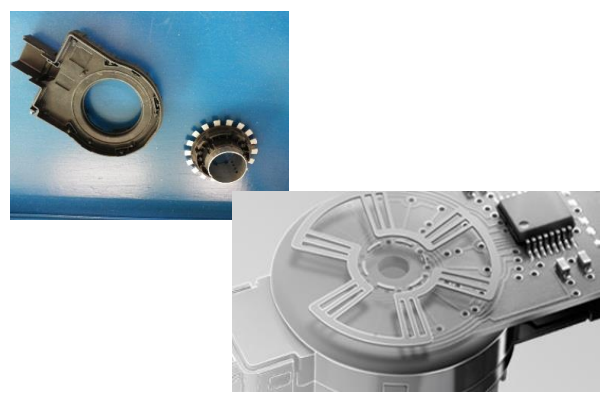

- Application in Mechatronics

- Sensor

- Sliders and actuators

- Gear transmissions clutch systems

- Bearings.

Properties

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Impact Properties

- Injection Molding

- Note

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

- Typical Properties

- Optimum plastic- plastic stick-slip performance

- Vibration dampening characteristics

- Abrasive wear resistance

| Value | Units | Test Method / Conditions | |

| Tensile Stress (Break) ¹¹ | 89 | MPa | ASTM D638 |

| Tensile Stress (Break) ¹¹ | 85 | MPa | ISO 527 |

| Tensile Strain (Break) ¹¹ | 6.3 | % | ISO 527 |

| Tensile Strain (Break) ¹¹ | 5.9 | % | ASTM D638 |

| Tensile Modulus (at 5 mm/min) ¹¹ | 3680 | MPa | ASTM D638 |

| Flexural Stress ¹¹ | 131 | MPa | ASTM D790 |

| Flexural Stress ¹¹ | 107 | MPa | ISO 178 |

| Flexural Modulus ¹¹ | 3500 | MPa | ISO 178 |

| Flexural Modulus ¹¹ | 3930 | MPa | ASTM D790 |

| Tensile Modulus (at 1 mm/min) ¹¹ | 3800 | MPa | ISO 527 |

| Value | Units | Test Method / Conditions | |

| Density ¹¹ | 1.23 | g/cm³ | ISO 1183 |

| Density ¹¹ | 1.24 | g/cm³ | ASTM D792 |

| Mold Shrinkage (flow, 24 hrs) ᵍ ¹¹ | 1 - 1.5 | % | ASTM D955 |

| Mold Shrinkage (xflow, 24 hrs) ᵍ ¹¹ | 1.2 - 1.7 | % | ASTM D955 |

| Wear Factor Washer ¹¹ | 23 | 10^-10 in^5-min/ft-lb-hr | ASTM D3702 Modified: Manual |

| Dynamic COF ¹¹ | 0.38 | — | ASTM D3702 Modified: Manual |

| Static COF ¹¹ | 0.32 | — | ASTM D3702 Modified: Manual |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ | 171 | °C | ASTM D648 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, flow) ¹¹ | 0.000067 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, flow) ¹¹ | 0.000068 | 1/°C | ISO 11359-2 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, xflow) ¹¹ | 0.000097 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, xflow) ¹¹ | 0.000098 | 1/°C | ISO 11359-2 |

| Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 246 | °C | ISO 75/Bf |

| Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 160 | °C | ISO 75/Af |

| Value | Units | Test Method / Conditions | |

| Izod Impact (Unnotched, at 23°C) ¹¹ | 534 | J/m | ASTM D4812 |

| Izod Impact (Notched, at 23°C) ¹¹ | 46 | J/m | ASTM D256 |

| Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ | 37 | kJ/m² | ISO 180/1U |

| Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ | 4 | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Drying Temperature ⁷ | 80 | °C | — |

| Drying Time ⁷ | 4 | Hrs | — |

| Maximum Moisture Content ⁷ | 0.15 - 0.25 | % | — |

| Melt Temperature ⁷ | 275 - 290 | °C | — |

| Front - Zone 3 Temperature ⁷ | 295 - 305 | °C | — |

| Middle - Zone 2 Temperature ⁷ | 280 - 295 | °C | — |

| Rear - Zone 1 Temperature ⁷ | 265 - 275 | °C | — |

| Mold Temperature ⁷ | 80 - 95 | °C | — |

| Back Pressure ⁷ | 0.2 - 0.3 | MPa | — |

| Screw Speed ⁷ | 30 - 60 | rpm | — |

Packaging & Availability

- Regional Availability