Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Potential Benefits of LEXAN EXL Resin

- Impact: Best-in-class ductility to -60 ºC with an outstanding balance of ductility and viscosity.

- Weatherability: Excellent retention of mechanical properties upon outdoor exposure.

- Aging: Better retention of properties vs. other polycarbonate resins.

- Flame retardance: FR grades can be used in many ECO-compliant applications.

- Knitline strength: A significant improvement over PC/ABS material

- Chemical resistance: Improved chemical resistance to some chemicals compared to standard polycarbonate

- Mechanical Recycling

Process

Debris are washed, melted & transformed into raw material for a new process. Focus on responsible sourcing of high-quality waste streams

Certification

Third-party certification of PCR content conducted by SCS Global Services

Value Proposition

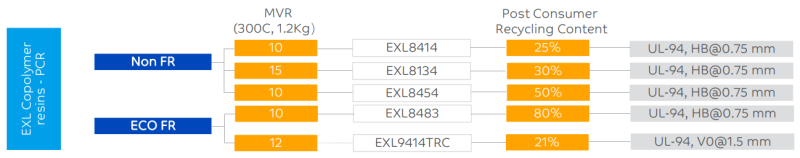

- 21-80% post-consumer recycled content

- Meeting RoHS1 guidelines

- Provides CO2

- reduction & waste depletion options

- Non-brominated & non-chlorinated flame retardant systems

- Up to 2 extra EPEAT points can be achieved

- Broad color space, enhanced performance via

- blending with copolymers

- Drop in solution to existing tools

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Color

- Flame Rating

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Impact Properties

- Injection Molding

- Flame Characteristics

- Note

ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

| Value | Units | Test Method / Conditions | |

| Tensile Stress (Yield, Type I, 50 mm/min) | 57 | MPa | ASTM D638 |

| Tensile Stress (Break, Type I, 50 mm/min) | 55 | MPa | ASTM D638 |

| Tensile Strain (Yield, Type I, 50 mm/min) | 6 | % | ASTM D638 |

| Tensile Strain (Break, Type I, 50 mm/min) | 100 | % | ASTM D638 |

| Tensile Modulus (at 5 mm/min) | 2200 | MPa | ASTM D638 |

| Flexural Stress (Yield, 1.3 mm/min, 50 mm span) | 90 | MPa | ASTM D790 |

| Flexural Modulus (at 1.3 mm/min, 50 mm span) | 2100 | MPa | ASTM D790 |

| Value | Units | Test Method / Conditions | |

| Mold Shrinkage (flow, 3.2 mm) | 0.4 - 0.8 | % | SABIC method |

| Melt Flow Rate (at 300°C, 1.2 kgf) | 15 | g/10 min | ASTM D1238 |

| Water Absorption (at 23°C, 24hrs) | 0.15 | % | SABIC method |

| Specific Gravity | 1.2 | — | ASTM D792 |

| Value | Units | Test Method / Conditions | |

| Vicat Softening Temperature (Rate B/50) | 145 | °C | ASTM D1525 |

| Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) | 123 | °C | ASTM D648 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, flow) | 0.00006 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, xflow) | 0.00006 | 1/°C | ASTM E831 |

| Relative Temperature Index (Electrical) ᵖ | 80 | °C | UL 746B |

| Relative Temperature Index (Mechanical with impact) ᵖ | 80 | °C | UL 746B |

| Relative Temperature Index (Mechanical without impact) ᵖ | 80 | °C | UL 746B |

| Value | Units | Test Method / Conditions | |

| Relative Permittivity (1 MHz) | 3 | — | ASTM D150 |

| Surface Resistivity | min. 1.E+15 | Ω | ASTM D257 |

| Volume Resistivity | min. 1.E+15 | Ω.cm | ASTM D257 |

| Dielectric Strength (in oil, at 0.8mm) | 15 | kV/mm | ASTM D149 |

| Dissipation Factor (at at 1 MHz) | 0.0092 | — | ASTM D150 |

| Hot Wire Ignition (PLC 3) | min. 3 | mm | UL 746A |

| Value | Units | Test Method / Conditions | |

| Izod Impact (Notched, at 23°C) | 800 | J/m | ASTM D256 |

| Izod Impact (Notched, at -30°C) | 700 | J/m | ASTM D256 |

| Izod Impact (Notched, at -40°C) | 650 | J/m | ASTM D256 |

| Instrumented Dart Impact Total Energy (at 23°C) | 70 | J | ASTM D3763 |

| Value | Units | Test Method / Conditions | |

| Back Pressure | 0.3 - 0.7 | MPa | — |

| Drying Temperature | 120 | °C | — |

| Drying Time | 3 - 4 | Hrs | — |

| Drying Time (Cumulative) | 48 | Hrs | — |

| Front - Zone 3 Temperature | 295 - 315 | °C | — |

| Maximum Moisture Content | 0.02 | % | — |

| Melt Temperature | 295 - 315 | °C | — |

| Middle - Zone 2 Temperature | 280 - 305 | °C | — |

| Mold Temperature | 70 - 95 | °C | — |

| Nozzle Temperature | 290 - 310 | °C | — |

| Rear - Zone 1 Temperature | 270 - 295 | °C | — |

| Screw Speed | 40 - 70 | rpm | — |

| Shot to Cylinder Size | 40 - 60 | % | — |

| Vent Depth | 0.025 - 0.076 | mm | — |

| Value | Units | Test Method / Conditions | |

| UL Recognized (94HB Flame Class Rating) ᵖ | min. 0.75 | mm | UL 94 |

| Glow Wire Ignitability Temperature (at 3.0 mm) ᵖ | 875 | °C | IEC 60695-2-13 |

| Glow Wire Ignitability Temperature (at 1.5 mm) ᵖ | 875 | °C | IEC 60695-2-13 |

| Glow Wire Ignitability Temperature (at 1.0 mm) ᵖ | 875 | °C | IEC 60695-2-13 |

| Glow Wire Ignitability Temperature (at 0.75 mm) ᵖ | 850 | °C | IEC 60695-2-13 |

| Glow Wire Flammability Index (at 3 mm) ᵖ | 960 | °C | IEC 60695-2-12 |

| Glow Wire Flammability Index (at 1.5 mm) ᵖ | 850 | °C | IEC 60695-2-12 |

| Glow Wire Flammability Index (at 1 mm) ᵖ | 850 | °C | IEC 60695-2-12 |

| Glow Wire Flammability Index (at 0.75 mm) ᵖ | 825 | °C | IEC 60695-2-12 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- EXL Copolymer Resins: Low Temperature, High Impact Resistance with Post Consumer Recycling Material Solutions

Packaging & Availability

- Regional Availability