Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- ULTEM™ Resin For Battery Operated AR/VR Glasses

- High strength to weight ratio enables a thin wall, light weight design.

- Excellent balance of strength and resilience, in addition to light weight, offers flexibility for designers to deliver both comfort and functionality.

- High dimensional stability supports efficient assembly of electronic components.

- ULTEM™ resin’s inherent FR eliminates the need for an additional FR agent, which can cause materials, such as amorphous nylon, to be more brittle and less resilient.

- Adheres to IEC62368-1 electronic safety standards.

- ULTEM™ Photonics Applicational Benefits

- Design Freedom & Miniaturization : Thermoplastics can help enable complex part designs for pluggable and co-packaged optics to replace solutions like glass or thermoset resins. Potential applications include aspherical lenses or lens arrays.

- Integration and Simplification : Thermoplastics are well-suited for the integration of mechanical and optical features to simplify design and assembly for potential cost improvement. Examples include alignment fixtures and overmolding of other thermoplastic materials.

- Mass Production with High Precision : Injection molding of thermoplastics can help enable high precision manufacturing of complex parts at large build numbers.

- Assembly of Mixed Materials : Integration of multiple components can be accomplished with two-shot injection molding:

- Optical and light blocking

- Optical and rigid alignment/mounting

- Ultem Resin Attributes for Eyewear Frames

- Super tough

- Meets JIS B7285, includes 20,000 cycles blending repetitions

- Long life cycle

- UV stabilized

- Light weight

- Excellent in chemical and hydrolytic resistance

- Excellent dimensional stability

- Thin wall molding down to 1.2 mm

- Long term heat resistance (RTI > 170°C)

- Available in custom colors

ULTEM resin delivers a broad range of desirable performance properties for eyeglass frames and is also potentially usable in safety and 3D eyewear frames.

Dimensional and Hydrolytic Stability

- Ensures the lenses are retained in the frame

- Extends the product life cycle

Temperature and Chemical Resistance

- Excellent stain and chemical resistance

- High heat deflection temperature protects the frames even when left on the car dashboard in direct sunlight

Design Freedom & Ease of Production

- Precision thin wall molding at 1.2 mm

- Capability for custom colors providing a wide range of esthetic effects

- Enhanced processing window vs. nylons

Density

- Intrinsically lightweight (up to 50% vs. metal)

Mechanical Properties

- Higher flexural modulus at 3510MPa

- Offers elasticity coupled with resistance to deformation, allowing the frame to bend easily yet return to its original shape

- ULTEM™ Resin Offers

- Lead times of approximately 4 weeks*

- Up to 55% higher stiffness

- Better dimensional stability vs. PSU

- Excellent property retention at elevated temps:

Tg - 217°C, HDT @ 1.80 MPa: 190°C

- Up to 17% lower CTE than PES/PPSU

- Chemical resistance

- Metal plating compatibility

- Compatibility with multiple sterilization methods

- Availability for stock shapes & films

- Product Highlight

The ULTEM™ family of amorphous thermoplastic polyetherimide (PEI) resins offer outstanding elevated thermal resistance, high strength and stiffness, and broad chemical resistance. ULTEM™ copolymers are also available for even higher heat, chemical and elasticity needs.

ULTEM™ resins uniquely balance both mechanical properties and processability, offering design engineers exceptional flexibility and freedom. ULTEM™ resins are also inherently flame retardant and possess excellent dielectric character. ULTEM™ resins are therefore an excellent candidate for your electric vehicle battery needs where high heat resistance is required.

With its appreciable flow and dimensional stability, coupled with excellent resistance to Li-ion electrolyte, ULTEM™ resins such as ULTEM™ CRS5011 resin are today being used for insulation of Li-ion cell terminals. Given its excellent dielectric character, ULTEM™ resin is also an ideal candidate for bus bar insulation. For other powertrain elements, such as DC power converters. ULTEM™ UTF120 dielectric film is already enabling high temperature film capacitors.

- Product Highlights

- Long lasting reliability : Modulus & strength retention after 80°C/85H at1000hrs

- Stable optic signals with temperature : Dimensional stability over thermal range of -20°C to ~150°C

- Stable optic signals with humidity : Dimensional robustness over broad environmental humidity

- Passing 200 insertion tests : Balanced ductility and stiffness performance

- Thin-wall flame resistance : Inherent FR characteristics, halogen and PFAS-free

- Proven economical mass production : Easy processing with tight tolerance through molding

- Colored solutions : Compliance to IEC 61249-2-21 , IPC 4101E and JEDEC JS709B

- Key Benefits

- Heat Resistance

- Dimensional Stability

- Dielectric Performance

- Miniaturization and Thin Wall

- Resilience

- Product Benefits

- High temperature resistance, haze onset temperature up to 230°C, near-IR transparency for better heat dissipation

- Excellent dimensional stability, low CTE, good creep resistance

- Lightweight solution compared to metal & glass

- Low outgassing to help limit potential risk of headlight contamination

- Direct metallization, primer-free, more environmentally cautious

- Design freedom, high productivity, system cost saving

- Availability of ISCC+ certified bio-based solutions

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Potential Applicational Features

- Fiber Optical Connector

- High IR transmission

- High refractive index

- Low CTE 25 - 200°C

- Design for easy assembly

- On Board Lens Array

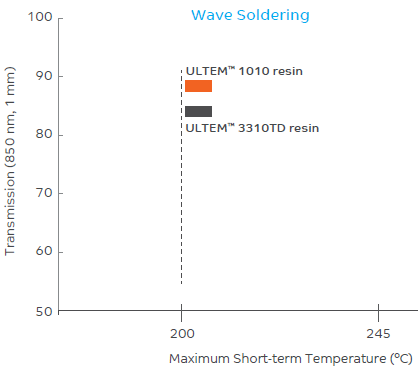

- Can withstand reflow soldering peak temperature up to 260°C

- Complex interconnect designs for co-packaged optics

- Sensor Lens

- Option for partial overmolding to reduce light scattering

- High IR transmission

- High flow for complex tooling

- Fiber Optical Connector

- Applications in Various Industries

- Mobilty

- Connectors

- Water

- Food Service

- Healthcare

- Aerospace

- 5G Antennas / Radomes

- Semiconductors

Properties

- Flame Rating

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Processing Information (Extrusion Blow Molding)

- Impact Properties

- Injection Molding

- Flame Characteristics

- Note

- ᵃ Back Pressure, Screw Speed, Shot to Cylinder Size and Vent Depth are only mentioned as general guidelines. These may not apply or need adjustment in specific situations such as low shot sizes, thin wall molding and gas-assist molding. Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ʳ UL Ratings shown on the technical datasheet might not cover the full range of thicknesses, colors and regions. For details, please see the UL Yellow Card.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

| Value | Units | Test Method / Conditions | |

| Ball Indentation Hardness (H358/30) ¹¹ | 140 | MPa | ISO 2039-1 |

| Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ | 3200 | MPa | ASTM D790 |

| Flexural Modulus (at 2 mm/min) ¹¹ | 3300 | MPa | ISO 178 |

| Flexural Modulus (at 2.6 mm/min, 100 mm span) ¹¹ | 3400 | MPa | ASTM D790 |

| Flexural Stress (Yield, 1.3 mm/min, 50 mm span) ¹¹ | 165 | MPa | ASTM D790 |

| Flexural Stress (Yield, 2.6 mm/min, 100 mm span) ¹¹ | 160 | MPa | ASTM D790 |

| Flexural Stress (Yield, at 2 mm/min) ¹¹ | 160 | MPa | ISO 178 |

| Hardness (Rockwell M) ¹¹ | 109 | — | ASTM D785 |

| Hardness (Rockwell M) ¹¹ | 106 | — | ISO 2039-2 |

| Taber Abrasion (CS-17, 1 kg) ¹¹ | 10 | mg/1000cy | ASTM D1044 |

| Tensile Modulus (at 1 mm/min) ¹¹ | 3200 | MPa | ISO 527 |

| Tensile Modulus (at 5 mm/min) ¹¹ | 3350 | MPa | ASTM D638 |

| Tensile Strain (Break, 50 mm/min) ¹¹ | 50 | % | ISO 527 |

| Tensile Strain (Break, Type I, 5 mm/min) ¹¹ | 60 | % | ASTM D638 |

| Tensile Strain (Break, Type I, 50 mm/min) ¹¹ | 60 | % | ASTM D638 |

| Tensile Strain (Yield, 50 mm/min) ¹¹ | 6 | % | ISO 527 |

| Tensile Strain (Yield, Type I, 5 mm/min) ¹¹ | 7 | % | ASTM D638 |

| Tensile Strain (Yield, Type I, 50 mm/min) ¹¹ | 7 | % | ASTM D638 |

| Tensile Stress (Yield, 50 mm/min) ¹¹ | 110 | MPa | ISO 527 |

| Tensile Stress (Yield, Type I, 5 mm/min) ¹¹ | 110 | MPa | ASTM D638 |

| Tensile Stress (Yield, Type I, 50 mm/min) ¹¹ | 115 | MPa | ASTM D638 |

| Value | Units | Test Method / Conditions | |

| Density ¹¹ | 1.27 | g/cm³ | ISO 1183 |

| Moisture Absorption (at 23°C, 50% RH, 24hrs) ¹¹ | 0.2 | % | ISO 62-4 |

| Moisture Absorption (at 23°C, 50% RH, Equilibrium) ¹¹ | 0.7 | % | ISO 62-4 |

| Water Absorption (at 23°C, 24hrs) ¹¹ | 0.25 | % | ASTM D570 |

| Water Absorption (at 23°C, 24hrs) ¹¹ | 0.25 | % | ISO 62-1 |

| Water Absorption (at 23°C, saturated) ¹¹ | 1.25 | % | ASTM D570 |

| Water Absorption (at 23°C, saturated) ¹¹ | 1.25 | % | ISO 62-1 |

| Melt Volume Rate (at 360°C, 5.0 kg) ¹¹ | 25 | cm³/10 min | ISO 1133 |

| Melt Volume Rate (at 340°C, 5.0 kg) ¹¹ | 13 | cm³/10 min | ISO 1133 |

| Specific Gravity ¹¹ | 1.27 | — | ASTM D792 |

| Melt Flow Rate (at 337°C, 6.6 kgf) ¹¹ | 17.8 | g/10 min | ASTM D1238 |

| Poisson's Ratio ¹¹ | 0.36 | — | ASTM E132 |

| Mold Shrinkage (flow, 3.2 mm) ᵍ ¹¹ | 0.5 - 0.7 | % | SABIC method |

| Mold Shrinkage (xflow, 3.2 mm) ᵍ ¹¹ | 0.5 - 0.7 | % | SABIC method |

| Value | Units | Test Method / Conditions | |

| Ball Pressure Test (at 123°C to 127°C) ¹¹ | Pass | — | IEC 60695-10-2 |

| Coefficient of Thermal Expansion (at -20°C to 150°C, flow) ¹¹ | 0.000052 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at -20°C to 150°C, xflow) ¹¹ | 0.000052 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at -40°C to 150°C, flow) ¹¹ | 0.000052 | 1/°C | ISO 11359-2 |

| Coefficient of Thermal Expansion (at -40°C to 150°C, xflow) ¹¹ | 0.000052 | 1/°C | ISO 11359-2 |

| Heat Deflection Temperature (at 0.45 MPa, 3.2 mm, Unannealed) ¹¹ | 207 | °C | ASTM D648 |

| Heat Deflection Temperature (at 0.45 MPa, 6.4 mm, Unannealed) ¹¹ | 210 | °C | ASTM D648 |

| Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ | 190 | °C | ASTM D648 |

| Heat Deflection Temperature (at 1.82 MPa, 6.4 mm, Unannealed) ¹¹ | 201 | °C | ASTM D648 |

| Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 192 | °C | ISO 75/Af |

| Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 209 | °C | ISO 75/Bf |

| Relative Temperature Index (Electrical) ¹¹ | 170 | °C | UL 746B |

| Relative Temperature Index (Mechanical with impact) ¹¹ | 170 | °C | UL 746B |

| Relative Temperature Index (Mechanical without impact) ¹¹ | 170 | °C | UL 746B |

| Thermal Conductivity ¹¹ | 0.22 | W/m-°C | ASTM C177 |

| Thermal Conductivity ¹¹ | 0.22 | W/m-°C | ISO 8302 |

| Vicat Softening Temperature (Rate A/50) ¹¹ | 215 | °C | ISO 306 |

| Vicat Softening Temperature (Rate B/120) ¹¹ | 212 | °C | ISO 306 |

| Vicat Softening Temperature (Rate B/50) ¹¹ | 211 | °C | ISO 306 |

| Vicat Softening Temperature (Rate B/50) ¹¹ | 211 | °C | ASTM D1525 |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity ¹¹ | 1.00E+15 | Ω.cm | IEC 60093 |

| Volume Resistivity ¹¹ | 1.00E+17 | Ω.cm | ASTM D257 |

| Surface Resistivity (ROA) ¹¹ | min. 1.E+15 | Ω | IEC 60093 |

| Dielectric Strength (in oil, at 0.8mm) ¹¹ | 33 | kV/mm | IEC 60243-1 |

| Dielectric Strength (in oil, at 1.6mm) ¹¹ | 25 | kV/mm | IEC 60243-1 |

| Dielectric Strength (in oil, at 1.6mm) ¹¹ | 28 | kV/mm | ASTM D149 |

| Dielectric Strength (in oil, at 3.2mm) ¹¹ | 16 | kV/mm | IEC 60243-1 |

| Dielectric Strength (in oil, at 3.2mm) ¹¹ | 19.7 | kV/mm | ASTM D149 |

| Relative Permittivity (1 MHz) ¹¹ | 2.9 | — | IEC 60250 |

| Dissipation Factor (at at 1 MHz) ¹¹ | 0.006 | — | IEC 60250 |

| Relative Permittivity (50/60 Hz) ¹¹ | 2.9 | — | IEC 60250 |

| Dissipation Factor (at 50/60 Hz) ¹¹ | 0.0005 | — | IEC 60250 |

| Dielectric Constant (at at 1.1 GHz) ᵃ ¹¹ | 3.01 | — | — |

| Dielectric Constant (at at 10 GHz) ᵃ ¹¹ | 3.02 | — | — |

| Dielectric Constant (at at 5 GHz) ᵃ ¹¹ | 3.02 | — | — |

| Dissipation Factor (at at 1.1 GHz) ᵃ ¹¹ | 0.0012 | — | — |

| Dissipation Factor (at at 10 GHz) ᵃ ¹¹ | 0.0027 | — | — |

| Dissipation Factor (at at 5 GHz) ᵃ ¹¹ | 0.0024 | — | — |

| Comparative Tracking Index ¹¹ | 150 | V | IEC 60112 |

| Comparative Tracking Index (M) ¹¹ | 100 | V | IEC 60112 |

| Dielectric Strength (in air, at 1.6mm) ¹¹ | 32.7 | kV/mm | ASTM D149 |

| Relative Permittivity (100 Hz) ¹¹ | 3.15 | — | ASTM D150 |

| Dissipation Factor (at 100 Hz) ¹¹ | 0.0015 | — | ASTM D150 |

| Relative Permittivity (1 kHz) ¹¹ | 3.15 | — | ASTM D150 |

| Dissipation Factor (at at 1 kHz) ¹¹ | 0.0012 | — | ASTM D150 |

| Comparative Tracking Index (UL, PLC) ¹¹ | 4 | PLC Code | UL 746A |

| Hot Wire Ignition (PLC 1) ¹¹ | min. 3 | mm | UL 746A |

| Hot Wire Ignition (PLC 2) ¹¹ | min. 0.75 | mm | UL 746A |

| High Ampere Arc Ignition (PLC 3) ¹¹ | min. 3 | mm | UL 746A |

| High Ampere Arc Ignition (PLC 4) ¹¹ | min. 0.75 | mm | UL 746A |

| High Voltage Arc Track Rate (PLC) ¹¹ | 2 | PLC Code | UL 746A |

| Arc Resistance (Tungsten, PLC) ¹¹ | 5 | PLC Code | ASTM D495 |

| Value | Units | Test Method / Conditions | |

| Adapter - Zone 5 Temperature | 330 - 355 | °C | — |

| Barrel - Zone 1 Temperature | 325 - 350 | °C | — |

| Barrel - Zone 2 Temperature | 330 - 355 | °C | — |

| Barrel - Zone 3 Temperature | 330 - 355 | °C | — |

| Barrel - Zone 4 Temperature | 330 - 355 | °C | — |

| Die Temperature | 325 - 355 | °C | — |

| Drying Temperature | 140 - 150 | °C | — |

| Drying Time | 4 - 6 | Hrs | — |

| Drying Time (Cumulative) | 24 | Hrs | — |

| Head - Zone 6 - Top Temperature | 330 - 355 | °C | — |

| Head - Zone 7 - Bottom Temperature | 330 - 355 | °C | — |

| Maximum Moisture Content | 0.01 - 0.02 | % | — |

| Melt Temperature (Parison) | 320 - 355 | °C | — |

| Mold Temperature | 65 - 175 | °C | — |

| Screw Speed | 10 - 70 | rpm | — |

| Value | Units | Test Method / Conditions | |

| Charpy Impact (at -30°C, V-notch Edgew 80*10*4 sp=62mm) ¹¹ | 4 | kJ/m² | ISO 179/1eA |

| Charpy Impact (at 23°C, V-notch Edgew 80*10*4 sp=62mm) ¹¹ | 4 | kJ/m² | ISO 179/1eA |

| Color (at 23°C) ¹¹ | 33 | J | SABIC method |

| Izod Impact (Notched, 80*10*4, at -30°C) ¹¹ | 5 | kJ/m² | ISO 180/1A |

| Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ | 5 | kJ/m² | ISO 180/1A |

| Izod Impact (Notched, at -30°C) ¹¹ | 41 | J/m | ASTM D256 |

| Izod Impact (Notched, at 23°C) ¹¹ | 32 | J/m | ASTM D256 |

| Izod Impact (Reverse Notched, 3.2 mm) ¹¹ | 1174 | J/m | ASTM D256 |

| Izod Impact (Unnotched, 80*10*4, at -30°C) ¹¹ | No break | kJ/m² | ISO 180/1U |

| Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ | No break | kJ/m² | ISO 180/1U |

| Izod Impact (Unnotched, at -30°C) ¹¹ | 1500 | J/m | ASTM D4812 |

| Izod Impact (Unnotched, at 23°C) ¹¹ | 1600 | J/m | ASTM D4812 |

| Value | Units | Test Method / Conditions | |

| Back Pressure ⁷ | 0.3 - 0.7 | MPa | — |

| Drying Temperature ⁷ | 150 | °C | — |

| Drying Time (Cumulative) ⁷ | 24 | Hrs | — |

| Drying Time ⁷ | 4 - 6 | Hrs | — |

| Front - Zone 3 Temperature ⁷ | 345 - 415 | °C | — |

| Maximum Moisture Content ⁷ | 0.02 | % | — |

| Melt Temperature ⁷ | 350 - 410 | °C | — |

| Middle - Zone 2 Temperature ⁷ | 340 - 405 | °C | — |

| Mold Temperature ⁷ | 135 - 180 | °C | — |

| Nozzle Temperature ⁷ | 345 - 405 | °C | — |

| Rear - Zone 1 Temperature ⁷ | 330 - 400 | °C | — |

| Screw Speed (Circumferential speed) ⁷ | 0.2 - 0.3 | m/s | — |

| Shot to Cylinder Size ⁷ | 40 - 60 | % | — |

| Vent Depth ⁷ | 0.025 - 0.076 | mm | — |

| Value | Units | Test Method / Conditions | |

| Glow Wire Flammability Index (passes at 960°C) ʳ ᵖ | 3.2 | mm | IEC 60695-2-12 |

| NBS Smoke Density (Flaming, Ds 4 min) ᵖ | 2 | — | ASTM E662 |

| Oxygen Index (LOI) ᵖ | 47 | % | ISO 4589 |

| Oxygen Index (LOI) ᵖ | 44 | % | ASTM D2863 |

| UL Recognized (94-5VA Flame Class Rating) ᵖ | min. 3 | mm | UL 94 |

| UL Recognized (94V-0 Flame Class Rating) ᵖ | min. 0.75 | mm | UL 94 |

| UL Recognized (94V-2 Flame Class Rating) ᵖ | min. 0.4 | mm | UL 94 |

Regulatory & Compliance

- Certifications & Compliance

- OEM Specifications

- Quality Standards

- ULTEM™ Resin May Support

- Electrical: UL94 V0 & 5VA, UL94 F1, UL746B

- Telecom: Telcordia GR-326, TIA/EIA-604-10A

- Mobility: FMVSS, IATF 16949, ISO 14001

- Food Service: FDA, NSF, EFSA, JHOSPA

- Water: NSF, WRAS, KTW

- Semiconductors: FM

- Healthcare: ISO 10993, FDA, USP Class VI, compatible with multiple sterilization methods

- Aerospace: ABD 0031, BMS, FAR25.853, OSU 55/55 & NBS smoke density tests

Technical Details & Test Data

- Lightweight Solution In AR Glasses With ULTEM™ Resin

Balance of Comfort & Performance

LLVISION wanted to develop a new generation of AR glasses that uses artificial intelligence (AI) to help individuals with hearing-loss to “see the voice” during conversation. The new product, named “LEION Hey”, was the first to be designed for consumer usage, offering an embedded 400mAh battery and eliminating the need for cables. However, the additional functionality added to the total weight of the glasses, making them potentially uncomfortable to wear on daily basis. The challenge arose to find a lightweight, flame retardant (FR), and high-performance material to reduce the total weight to less than 80 grams. The material also needed to be compliant with IEC 62368-1 electronic safety standards since the onboard computer and battery are integrated into the legs.

The Solution : High Strength ULTEM™ 1000 Resin

SABIC proposed ULTEM™ 1000 resin, a high performance, inherent FR polyetherimide (PEI) material, for consideration in the legs of LLVISION “LEION Hey” AR glasses. The high strength-toweight ratio of ULTEM™ resin helped LLVISION to address their key challenges. In addition, the excellent balance of stiffness and resilience of ULTEM™ resin provided the right clamping force, giving the end-user an overall more comfortable wearing experience. Compared to incumbent amorphous nylon solutions, the excellent dimensional stability of the ULTEM™ material supported LLVISION to create a more efficient assembly of the electronic components within the legs.

- High Heat Withstanding Property of ULTEM Resin for Opto-electronic Solder Process

ULTEM Polyetherimide Resin

- ULTEM resins are near infrared transparent, amorphous thermoplastic resins with a low thermal expansion coefficient (CTE). They have been used for (multi mode) optical lens assemblies in photonics for decades based on a perfect properties fit for this application area.

- The new ULTEM 3310TD resin offers ~ 30% reduction in CTE while retaining optical transmission and is well-suited where extra tight alignment tolerances are required, like lenses for single mode optics in data centers.

- Test Data

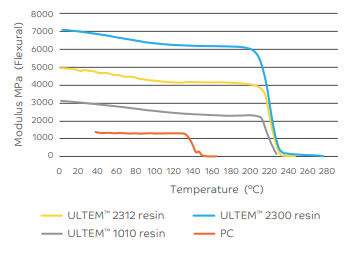

Modulus VS. Temperature

ULTEM resin maintains high modulus up to 217 °C.

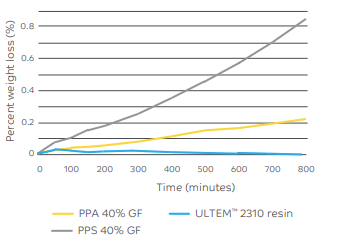

Weight loss in TGA at 225°C/437°F. Samples conditioned 24hrs at 120°C

ULTEM resin outperforms glass-filled PPA and glass-filled PPS with lower outgassing performance.

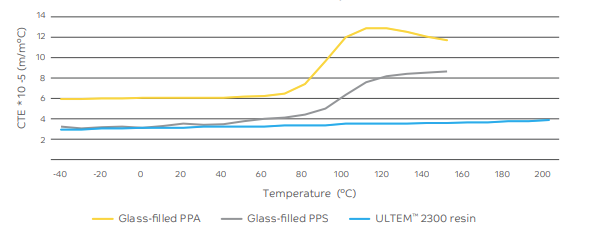

Coefficient of Thermal Expansion

Compared with glass-filled PPA and glass-filled PPS, ULTEM resin keeps a low and stable CTE between -40°C to 200°C and maintains better dimensional stability over a wide temperature range.

Packaging & Availability

- Country Availability

- Regional Availability

- Availability

ULTEM™ resin is available in transparent and opaque custom colors, and can be glass filled for added stiffness.