Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Product Families

- Composition

Composition Main Chain Functional Group Polypropylene Carboxylic anhydride group

Features & Benefits

- Materials Features

- Civil Engineering and Construction

1) Improvement of Asphalt Heat Resistance

The following UMEX products improve asphalt heat resistance by increasing its softening

point.Name of recommended product UMEX 100TS and UMEX 110TS Standard Amount to be added Between 2 and 10 wt % 4. Example Process for Using UMEX Products

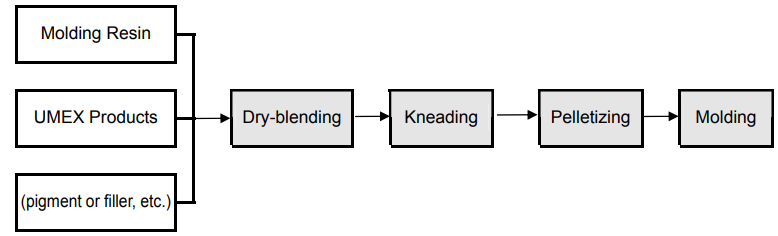

A standard example process for using UMEX products is shown below:Example of Molding Resins and Kneading Temperature

Polypropylene approx. 210 °C ABS resin approx. 230 °C Polyamide approx. 240 °C Polybutylene terephthalate approx. 270 °C

Figure 2. Example Process for Using UMEX Products

Precaution Against Mishandling

- The properties of resin may become worse when the UMEX products are used with the resin in excessive quantities due to being the modified low-molecular-weight polyolefin. Before using the UMEX products, confirm the optimal application amount.

- As shown in Table 2-b on page 7, the compatibility with certain molding resins is insufficient, therefore the transparency may be affected. Before using the UMEX products, confirm the compatibility with resins.

- Performance

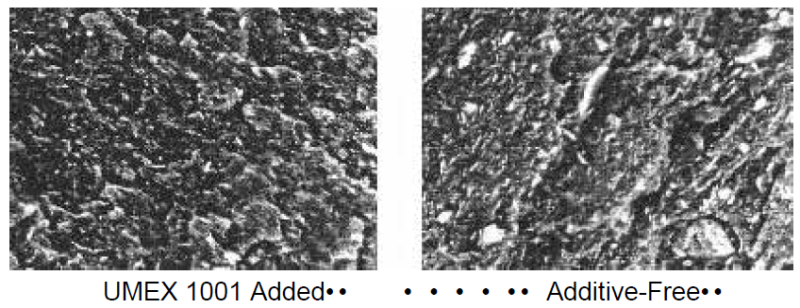

1. Improvement in Dispersibility of Talc in Polypropylene

When either UMEX 1001 or UMEX 1010 is added to a mixture of talc and polypropylene, better molded materials which exhibit a higher tensile stress at yield, a higher flexural strength and a higher flexural modulus are obtained compared with conventional molded materials containing either untreated talc and an acid modified polypropylene or treated talc.Table 3. Improvement in Dispersibility of Talc in Polypropyleneô€€

Formula and Mechanical Property Formula 1 Formula 2 Formula 3 Formula 4 UMEX 1001 UMEX 1010 Acid Modified

PolypropyleneAdditive-Free Polypropylene * wt % 70 70 70 70 Talc (untreated) wt % 30 30 30 .. Talc (treated) wt % ..

.. .. 30 UMEX 1001 wt % 3 .. UMEX 1010 wt % .. 3 .. .. Conventional acid modified polypropylene wt % .. .. 5 Tensile stress at yield MPa 39 39 37 35 Elongation % 8 7 18 22 Flexural strength MPa 55 57 53 51 Flexural modulus MPa 3,400 3600 3,200 3000 Izod impact strength (23 °C) kJ/m 4 3 4 4 Deflection temperature under load

(1.813 MPa) °C78 78 80 82 * Available on the market, MFR 9 g (230 °C, 21.18 N, 10 min), injection-molding grade

Materials and Methods:

Materials:

According to Formulas 1 to 4 described in Table 3, each of the compounds was kneaded using a twin-screw extruder at 210 °C, and then molded using an injection molding machine (nozzle temperature: 210 °C).Methods:

Tensile stress at yield, elongation Measured according to ASTM D 638. Flexural strength, flexural modulus Measured according to ASTM D 790. Izod impact strength Measured with a notch according to ASTM D 256. Deflection temperature under load Measured with the flexural stress of 1.813 MPa according to ASTM D648.

Figure 4. Scanning Electron Micrograph of a Frozen Fractured Cross Section of Polypropylene with Dispersed Talc

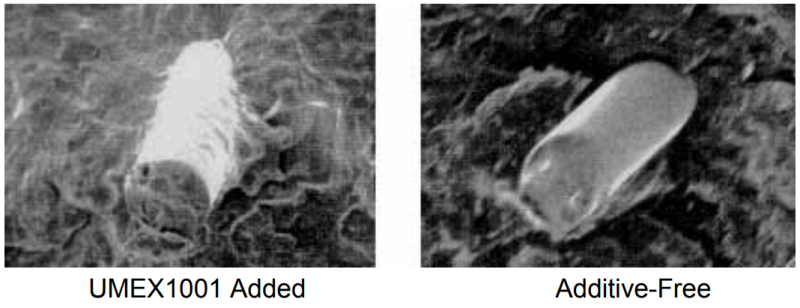

2. Improvement in Adhesion of Fiberglass to Polypropylene

When either UMEX 1001 or UMEX 1010 is added to a mixture of fiberglass and polypropylene, better molded materials which exhibit a higher tensile stress at yield, a higher flexural strength and a higher flexural modulus are obtained compared with conventional molded materials containing either untreated fiberglass and acid modified polypropylene or treated fiberglass. Adhesion of fiberglass to polypropylene is also improved as shown in the electron micrograph in Figure 5.Table 4. Improvement in Adhesion of Fiberglass to Polypropylene

Formula and Mechanical Property Formula 1 Formula 2 Formula 3 Formula 4 UMEX 1001 UMEX 1010 Acid Modified

PolypropyleneAdditive-Free Polypropylene * wt % 70 70 70 70 Fiberglass (untreated) wt % 30 30 30 .. Fiberglass (treated) wt % ..

.. .. 30 UMEX 1001 wt % 5 .. UMEX 1010 wt % .. 5 .. .. Conventional acid modified polypropylene wt % .. .. 5 Tensile stress at yield MPa 46 44 44 42 Elongation % 5 4 4 4 Flexural strength MPa 100 100 95 91 Flexural modulus MPa 4700 4700 4500 4400 Izod impact strength (23 °C) kJ/m 14 13 15 16 Deflection temperature under load

(1.813 MPa) °C121 121 123 124 * Available on the market, MFR 9 g (230 °C, 21.18 N, 10 min), injection-molding grade

Materials and Methods:

Materials:- According to Formulas 1 to 4 described in Table 4, each of the compounds was kneaded using a twin-screw extruder at 210 °C, and then molded using an injection molding machine (nozzle temperature: 210 °C).

Methods:

See Table 3.

Figure 5. Scanning Electron Micrograph of a Frozen Fractured Cross Sectionô€€

of Polypropylene with Dispersed Fiberglass3. Improvement in Dispersibility of Calcium Carbonate in Polypropylene

When either UMEX 1001 or UMEX 1010 is added to a mixture of calcium carbonate and

polypropylene, the dispersibility is improved and better molded materials which exhibit a higher tensile strength, a higher flexural modulus and a higher deflection temperature under load are obtained.Table 5.Improvement in Dispersibility of Calcium Carbonate in Polypropylene

Formula and Mechanical Property Formula 1 Formula 2 Formula 3 UMEX 1001 UMEX 1010 Additive-Free Polypropylene * wt % 50 50 50 Ground calcium carbonate **

(untreated) wt %50 50 50 UMEX 1001 wt % 2.5 UMEX 1010 wt % 2.5 Tensile strength MPa 28.4 29.4 16.7 Elongation % 18 9 17 Flexural modulus MPa 2,724 2,744 2,656 Deflection temperature under load

(0.451 MPa) °C120 117 114 * Available on the market, MFR 9 g (230 °C, 21.18 N, 10 min), injection-molding gradeô€€

** Available on the marketMaterials and Methods:

Materials:

According to Formulas 1 to 3 described in Table 5, each of the compounds was kneaded using a twin-screw extruder at 210 °C, and then molded using an injection molding machine (nozzle temperature: 210 °C).Methods:

Tensile strength,elongation, flexural modulus Measured according to ASTM D 638. Deflection temperature under load Measured with the flexural stress of 0.451 MPa according to ASTM D648. 4. Improvement in Dispersibility of Cellulose Filler in Polypropylene

When either UMEX 1001 or UMEX 1010 is added to a mixture of cellulose type filler and

polypropylene, the dispersibility is improved and better molded materials which exhibit a higher tensile strength, a higher flexural modulus and a higher deflection temperature under load are obtained.Table 6. Improvement in Dispersibility of Cellulose Filler in Polypropylene

Formula and Mechanical Property Formula 1 Formula 2 Formula 3 UMEX 1001 UMEX 1010 Additive-Free Polypropylene * wt % 50 50 50 Pulp ** wt % 50 50 50 UMEX 1001 wt % 2.5 UMEX 1010 wt % 2.5 Tensile strength MPa 49.0 48.0 35.3 Elongation % 5 4 4 Flexural modulus MPa 4,812 4,900 4,586 Izod impact strength (23 °C) kJ/m 3 2 3 Deflection temperature under load

(0.451 MPa) °C156 155 149 * Available on the market, MFR 20 g (230 °C, 21.18 N, 10 min), injection-molding grade

** Available on the market, granulated to use as fillersMaterials and Methods:

Materials:

According to Formulas 1 to 3 described in Table 6, each of the compounds was kneaded using a twin-screw extruder at 210 °C, and then molded using an injection molding machine (nozzle temperature: 210 °C).Methods:

Tensile strength, elongation,

flexural modulusMeasured according to ASTM D638. Izod impact strength Measured with a notch according to ASTM D256. Deflection temperature under load Measured with a flexural stress of 0.451 MPa

according to ASTM D648.5. Effects of Surface Modification on Polyolefin

When UMEX 1010 is added to a mixture of ethylene propylene rubber and polypropylene, the surface of the molded resin is modified. The contact angle of liquid on the molded resin also decreases. Consequently, adhesion of the resin to a high polar paint (melamine type, polyurethane type, etc.) is improved dramatically.Table 7. Effects of Surface Modification on Polyolefin

Formula and Property Formula 1

UMEX 1010Formula 2

Additive-FreePolypropylene * wt % 50 50 Ethylene propylene rubber ** wt % 50 50 UMEX 1010 wt % 8 Contact angle ° 88 Sample 1 (unwashed) 99 Sample 1 (unwashed) 96 Sample 2 (washed) 100 Sample 2 (washed) Adhesion to high polar paint

(melamine type paint)80/100 Sample 1 (unwashed) 0/100 Sample 1 (unwashed) 80/100 Sample 2 (washed) 0/100 Sample 2 (washed)

* Available on the market, MFR 9 g (230 °C, 21.18 N, 10 min), injection-molding grade

** Resin-modifier gradeMaterials and Methods

Materials:

According to Formulas 1 to 2 described in Table 7, each of the compounds was kneaded using a twin-screw extruder at 210 °C, and then molded using an injection molding machine (nozzle temperature: 210 °C) . Each formula sample 1 was unwashed.

Each formula sample 2 was washed using a neutral detergent and rinsed.ô€€

Methods:

Contact angle

The test pieces were kept at 23 °C, 65 % R.H., and then the contact angle of water on the sample was measured using a contact angle tester.ô€€

Adhesion to high polar paint

The sample was painted using a bar coater No.4 with a car paint (melamine type), and dried at 120 °C for 30 min. It was then kept at ambient temperature (20±15 °C) for 24 hours. Next, a right angled grid pattern was cut from the surface of the painted sample using a cutter. The intervals between the cut lines were 1 mm each with a total of 100 squares formed by the lines.

Then, an adhesive cellophane tape was stuck to the prepared sample. The tape was quickly peeled off at an angle of 45 degrees to the surface. The adhesion was determined by the number of squares that still remained. The larger the number of the squares on the surface, the better the adhesion to the high polar paint.6. Improvement in Molding Processability on ABS Resin UMEX 110TS and UMEX 1010 improve fluidity and release properties of ABS resin when one of the products is added to the resin.

Table 8. Improvement in Molding Processability on ABS Resin

Formula and Property Formula 1

UMEX 110TSFormula 2

UMEX 1010Formula 3

Additive-FreeABS resin 100 100 100 UMEX 110TS 3 UMEX 1010 3 MFR

(200 °C, 49.03 N, 10 min) g18 12 4 Release property Very good Very good Considerable* Tensile strength MPa 44 48 50 Elongation % 10 10 15 Flexural strength MPa 73 75 75 Flexural modulus MPa 2,400 2,300 2,500 Izod impact strength (23 °C) kJ/m 12 12 12 Deflection temperature under load °C

(1.813 MPa)91 92 92 * A portion of the resins was not removed from the mold and remained there.ô€€

Materials and Methods:

Materials:

According to Formulas 1 to 3 described in Table 8, each of the compounds was kneaded using a twin-screw extruder at 230 °C, and then molded using an injection molding machine (nozzle temperature: 210 °C).

Methods:

MFR

MFR was measured according to ISO 1133 (JIS K 7210).

Release property A thick, flat four-sided embossed mold (80 × 80 × 2 mm) was used, and then the release property was evaluated.

Mechanical property

See Table 3.7. Improvement in Adhesive Strength of Hot Melt Adhesives

When either UMEX 100TS or UMEX 110TS is added to hot melt adhesives, the workability of the adhesives is enhanced because their melt viscosity decreases compared with a mixture of a viscosity depressant (low molecular polyolefin type), including polyethylene wax (Formula 3), and what is more, the UMEX products improve the peel strength and creep resistance.Table 9. Improvement in Adhesive Strength of Hot Melt Adhesives

Formula and Property Formula 1

UMEX 100TSFormula 2

UMEX 110TSFormula 3

Polyethylene WaxFormula 4

Additive-FreeStyrene elastomer 50 50 50 50 Tackifier (rosin type) 50 50 50 50 UMEX 100TS 10 UMEX 110TS 10 Polyethylene wax 10 Melt viscosity (200 °C,Adhesion) mPa.s 50,000 51,000 60,000 80,000 Peel strength (25 °C, Adhesion) kN/m 3.1 3.5 1.0 0.4 Creep resistance (70 °C, Adhesion) min 68 70 33 10 Materials and Methods:

Material:

According to Formulas 1 to 4 described in Table 9, each of the compounds was kneaded using a twin-screw extruder at 210 °C.

Methods:

Melt viscosity

Melt viscosity was measured at 200 °C using a Brookfield-type viscometer.

Peel strength (JIS K 6854) Two polypropylene films were joined together with the sample, and then cut into a 25 mm wide sample. The peel strength (T type) of the sample was measured at 25 °C according to JIS K 6854.

Creep resistance (JIS K 6859)

Two polypropylene films were joined together with the sample (the area of adhesion was 25 mm wide and 25 mm long, the length of non-adhesion films was 75 mm). Then, one of the non-adhesion films was fixed. A 500 g weight was hung on another non-adhesion film, and then the time required for its peeling off and completely dropping from the fixed film was measured. The measurement was conducted at 70 °C.8. Increase in the Softening Point of Asphalt

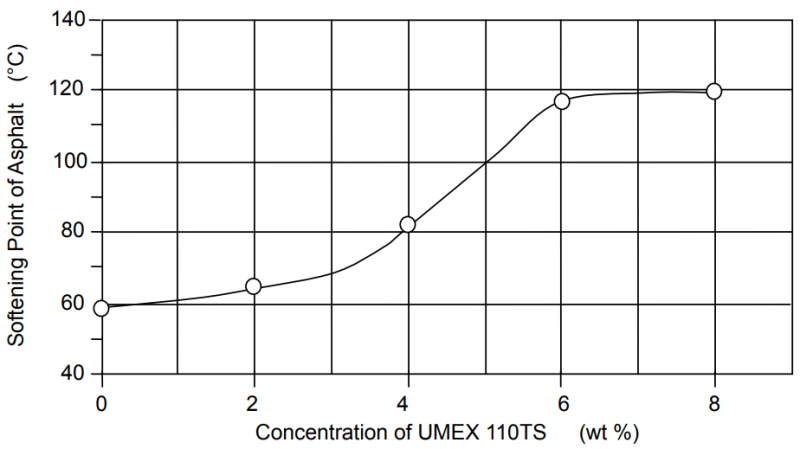

The softening point rises when UMEX 110TS is added to asphalt.

Figure 6. Improvement in Softening Point of Asphalt

Materials and Methods:

Material:

UMEX 110TS was added to asphalt, and then kneaded at 170 °C.

Method:

The softening point of the sample was measured according to ASTM E28-58T.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Reinforcements

- Adhesive & Sealant Type

- Industrial Additives End Use

- Plastics & Elastomers Processing Methods

- Applications

1. Main Applications of UMEX Products

Table 1 shows main applications of UMEX products.Table 1. Main Applications of UMEX Products

Improved Performance UMEX

100TSImprovement in filler dispersibility in polyolefin Good Improvement in pigment dispersibility in polyolefin Excellent Improvement in fiberglass adhesion to polyolefin - Improvement in polyolefin paintability* - Improvement in polyolefin film printability - Improvement in fluidity and adhesion of traffic paint for roads Good Improvement in fluidity and adhesion of hot melt adhesives Excellent Increase in softening point of asphalt Excellent Improvement in molding processability of ABS resin and polyamide resin Excellent * Paintability using paint of high polarity such as melamine type and polyurethane type (improvement of adhesion to paint)

2. Product Numbers of the UMEX Products and Features

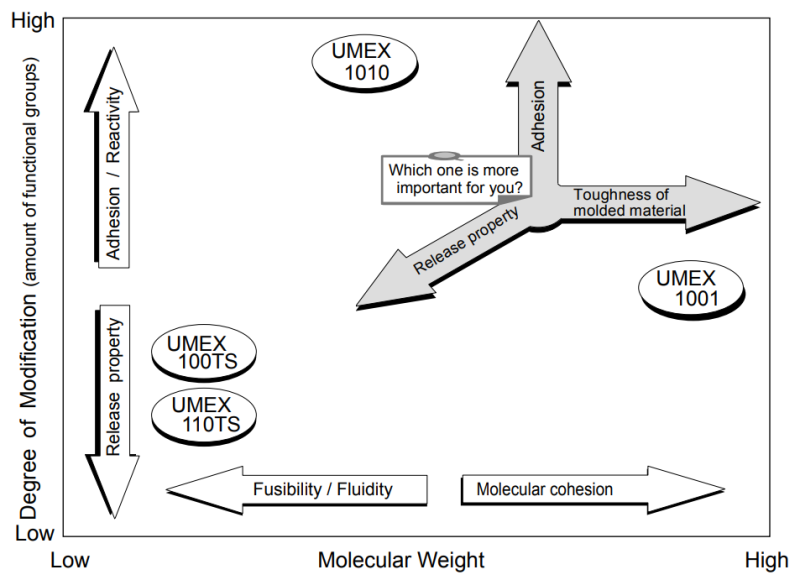

Figure 1 shows the features of each UMEX product. Select optimal UMEX products according to your blending needs.

Figure 1. Product Numbers of UMEX Products and Their Features ―Conceptual Drawing

3. Applications and the Standard Amount to be Applied

For each application, the standard amount to be applied of the UMEX products is shown below.

Properties

- Appearance

- Pale yellow powder

- Typical Properties

- Typical Properties

1. Typical Properties of UMEX Products

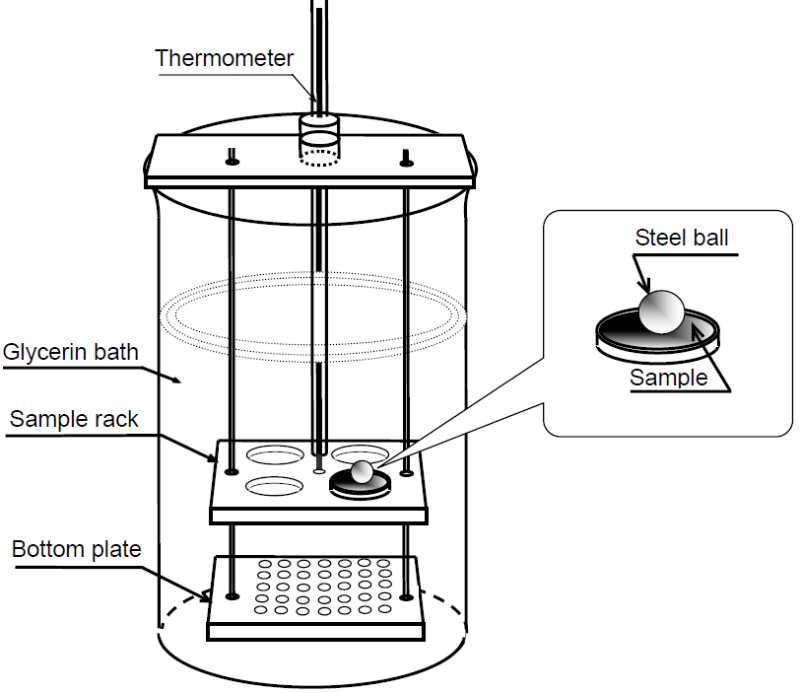

Table 2 shows the typical properties and compatibility with other resins.Main chain Polypropylene Functional group Carboxylic anhydride group Appearance Yellow granule Specific gravity (ASTM D 792) 0.95 Melt viscosity (160 °C) mPa·s 15,000 Softening point (JIS K 2531*) 153 Acid value (JIS K 0070) 26 * Softening point : According to JIS K 2531, a glycerin bath was heated at a rate of 5 °C/min and the sample was gradually softened. The temperature (softening point) was measured when the steel ball touched the bottom plate after passing through the sample.

Product Name/Compatibility Polyethylene Completely soluble (transparent) Polypropylene Completely soluble (transparent) Ethylene-vinylacetate copolymer Partially soluble (opaque, no separation into layers) Polyvinyl chloride Incompatible (opaque, separated into the original two layers) Polystyrene Incompatible (opaque, separated into the original two layers) Polyamide Completely soluble (transparent) Polycarbonate Partially soluble (opaque, no separation into layers) Polybutylene terephthalate Partially soluble (opaque, no separation into layers) Modified PPE Incompatible (opaque, separated into the original two layers) Polymethylmethacrylate Partially soluble (opaque, no separation into layers) ABS resin Partially soluble (opaque, no separation into layers) Value of symbols

UMEX Products and other resins were blended at a weight ratio of 5:95 and the mixture was melted.2. Heat Loss Property

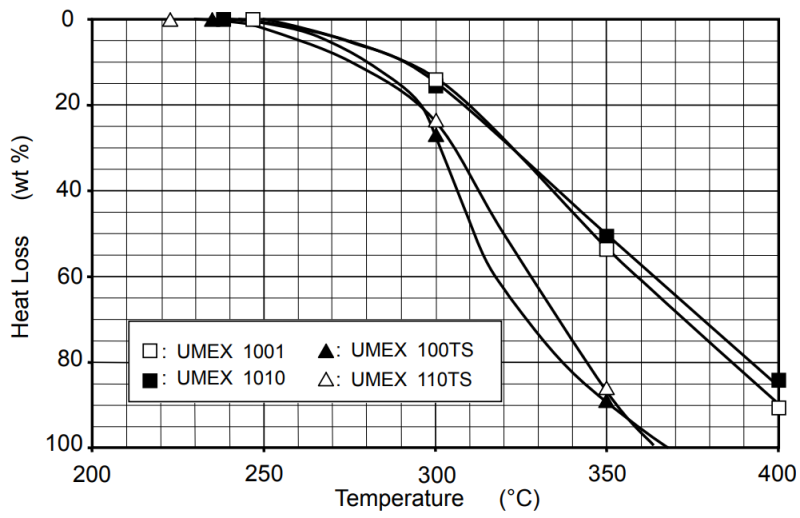

Figure 3 shows the heat loss properties of the UMEX products.

Figure 3. Heat Loss Property

Method:

- Apparatus: Apparatus for thermogravimetry

- Heating rate: 10 °C/min

- Ambience: Air

| Value | Units | Test Method / Conditions | |

| Acid Value | 3.5 | — | JIS K 0070 |

| Melt Viscosity (at 160°C) | 120 | mPa·s | — |

| Softening Point | 148 | — | JIS K 2531 |

| Specific Gravity | 0.89 | — | ASTM D 792 |

Technical Details & Test Data

- Resins and Rubber

1) Improvement in Inorganic Filler Dispersibility and Fiberglass Adhesion to Polyolefin

The following UMEX products assist in uniform dispersion of inorganic fillers such as talc,

magnesium hydroxide, etc. when added to polyolefin, thereby tough molded materials are

obtained. Also, when fiberglass is added, these products improve the adhesion of fiberglass to the resin, which also produce tough molded materials.Name of recommended product UMEX 1001 and UMEX 1010 Standard Amount to be added Between 1 and 5 wt % 2) Improvement of Polyolefin Paintability

Polar groups of the following UMEX products modify the surface of the polyolefin, thereby the adhesion to paint are improved.Name of recommended product UMEX 1001 and UMEX 1010 Standard Amount to be added Between 5 and 10 wt % 3) Improvement of Polyolefin Film Printability

Polar groups of the following UMEX products modify the surface of polyolefin film, thereby the printability of the film is improved.Name of recommended product UMEX 1001 and UMEX 1010 Standard Amount to be added Between 2 and 10 wt % 4) Improvement of Resin Molding Processability

The following UMEX products improve the fluidity of molten polyamide resin or molten ABS resin, thereby the molding processability is improved.Name of recommended product UMEX 1010, UMEX 100TS and UMEX 110TS Standard Amount to be added Between 1 and 5 wt % 5) Improvement of Pigment Dispersibility

When a color masterbatch is created using the following UMEX products and pigments for coloration of molding resins, the pigments disperse uniformly and the molded materials having excellent glossy surfaces are obtained.Name of recommended product UMEX 100TS and UMEX 110TS Standard Amount to be added Between 50 and 200 wt % to pigments - Adhesives

1) Increase in Softening Point of Hot Melt Adhesives

The following UMEX products increase the softening point of hot melt adhesives while decreasing the melt viscosity.Name of recommended product UMEX 100TS and UMEX 110TS Standard Amount to be added Between 2 and 10 wt %