Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- CAS No.

- 1318-23-6

- EC No.

- 215-284-3

- Technologies

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- CASE Ingredients Features

- Product Highlights

The unique product characteristics of Sasol dispersible boehmites can lead to many advantages for use in different systems. Some key features are:

- The high purity boehmites are produced under careful control to yield products with consistent quality and reliable performance.

- The powders are highly dispersible. Low-viscosity nano-sized particle sols can be prepared at room temperature in 10 to 30 minutes with concentrations of 10–40 wt.% AlOOH.

- The boehmites are versatile. They can be employed under a variety of application conditions, including low or high pH and low or high shear.

- Sasol also offers boehmites which are dispersible in polar and non-polar organic media.

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Base Chemicals End Uses

- Recommended Uses & Known Applications

The Sasol range of dispersible boehmites has traditionally been used in applications such as

- Sol-gel ceramics

- Catalysis

- Rrefractory materials

- Rheology control

- Surface frictionizing

Other applications include surface coating as well as paint detackification, polymer-

additives and functional fillers.

Properties

- Dispersible in

- Acid

- Chemical Properties

- Physical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Aluminium Oxide Content | min. 75 | % | — |

| Carbon Content | max. 0.5 | % | — |

| Ferric Oxide Content | max. 0.020 | % | — |

| Silicon Dioxide Content | max. 0.025 | % | — |

| Sodium Dioxide Content | max. 0.005 | % | — |

| Value | Units | Test Method / Conditions | |

| Crystallite Size (at 120) | 13 - 15 | nm | — |

| Dispersability | min. 97 | % | — |

| Loose Bulk Density | 0.30 - 0.65 | g/ml | — |

| Pore Radius | min. 9.0 | nm | — |

| Pore Volume (3 h/550 °C) | min. 1.0 | ml/g | — |

| Surface Area (3 h/550°C) | min. 150 | m²/g | — |

| Value | Units | Test Method / Conditions | |

| Particle Size Distribution (at < 25μm) | max. 55 | % | — |

| Particle Size Distribution (at < 45μm) | min. 50 | % | — |

| Particle Size Distribution (at < 95μm) | min. 85 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Preparation of DISPERAL HP 14 Dispersions

In non-polar solvent (toluene or xylene)

In order to prepare a DISPERAL HP 14 dispersion of 25 wt % DISPERAL HP 14 content, put 50 g of DISPERAL HP 14 powder and 16.7 g of wetting agent MARLOWET 4538 (available from Sasol) under intensive stirring into 133.3 g of xylene or toluene. Mix it with a stirrer and ultrasound for about two minutes. Typically the viscosity is below 10 mPa·s.

In polar solvent (isopropanol)

In order to prepare a DISPERAL HP 14 dispersion of 20 wt % DISPERAL HP 14 content, put 40 g of DISPERAL HP 14 powder and 20 g of wetting agent MARLOWET 4538 (available from Sasol) under intensive stirring into 140 g of isopropanol. Mix it with a stirrer and ultrasound for about two minutes. Typically the viscosity is below 10 mPa·s.

In water at pH 3 - 5

In order to prepare an alumina sol of 10 (30) wt % solid content, pour 10 g (30 g) of DISPERAL HP 14 powder under intensive stirring into 90 g (70 g) of 0.31 – 0.32 (0.94 – 1.25)% HNO3. After stirring for 30 minutes, the sol is ready for use. The viscosity of this sol is below 10 (100) mPa·s. Under aforesaid conditions DISPERAL HP 14 offers a dispersability (20 minutes at 2,400 rpm) of minimum 97 % at a pH value of 3.0 – 4.0. The dispersion can be diluted with water afterwards if necessary.

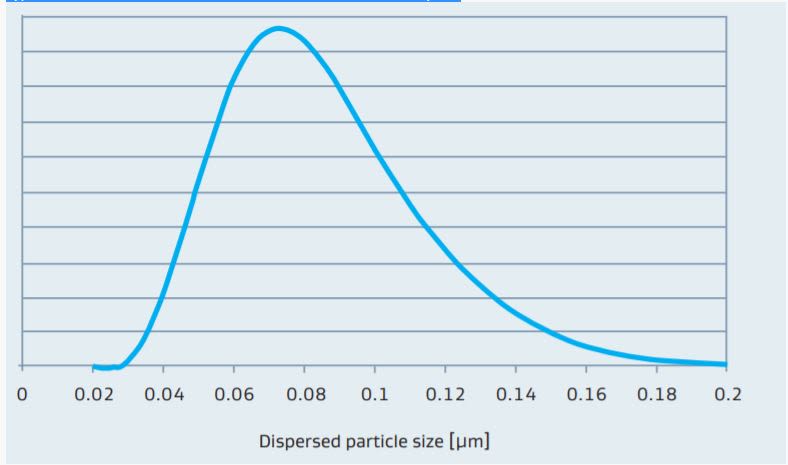

- Particle Size Distribution

Typical Particle Size Distribution of DISPERAL HP 14 in Water at pH 4

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Storage and Handling

DISPERAL boehmite powders are mildly abrasive materials having a Mohs hardness of 3.5 to 4.0. Therefore, handling and storage equipment should be designed for such materials. Examples are aluminum, abrasion resistant carbon steel and polypropylene or epoxy-lined steel. Blower or vacuum systems can be used to move the powders. A minimum of 4,000 ft/min fluidizing velocity is recommended. Boehmite powders will absorb atmospheric moisture and facilities should be designed appropriately. The liquids are readily pumpable using standard centrifugal or positive displacement pumps. Due to the pH range of available products, recommended materials for process equipment include stainless steel, or polymeric-lined steel.

DISPERAL boehmite powders are classified as non-toxic nuisance dusts. Exposure to high concentrations of dust may cause physical irritation and drying of skin and eye tissues. Repeated or prolonged contact with alumina sols may cause irritation as well. Handling and shipping procedures should be designed to avoid such contact and to minimize the inhalation of airborne dust. Normal good laboratory practices and operating procedures should ensure personnel safety.