Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- INCI Name

- Ingredient Origin

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Fluids & Lubricants Functions

- CAS No.

- 68439-50-9

- EC No.

- 500-213-3

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- HII Features

- Performance Characteristics

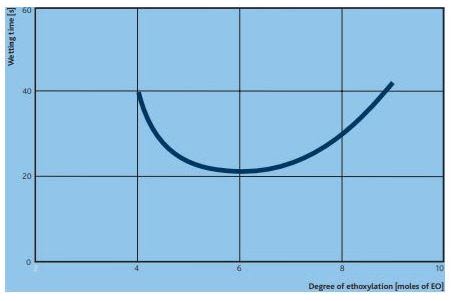

Wetting Efficiency On Textiles

The products of the MARLIPAL 24 series provide excellent wetting performance on textiles, the best values being observed for MARLIPAL 24/40 to MARLIPAL 24/90. The wetting effect, which, in accordance to DIN EN 1772, corresponds to the time taken for a cotton disk to sink in aqueous solution, is shown as a function of the degree of ethoxylation. The shorter the sinking time, the better the wetting efficiency.

Wetting efficiency on textiles Cotton disk method, 20°C, 1 g/l in D.I. water

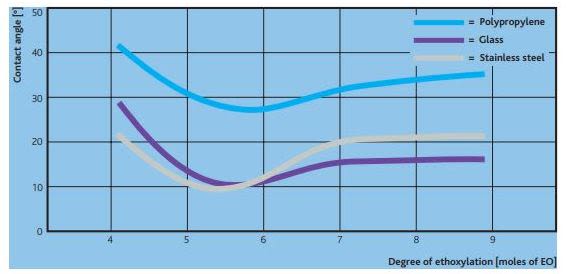

Wetting Efficiency On Hard Surfaces

The MARLIPAL 24 grades show an excellent reduction of the contact angles on all surfaces. The performance is a function of the ether chain length and usually one will find a performance optimum at medium EO chain length. The contact angles of MARLIPAL 24 surfactants dissolved in water with a concentration of 1 g/l are displayed on three different surfaces in dependence of the glycol ether chain length. The best wetting performance is found for the MARLIPAL 24 ethoxylates with 5 to 7 moles EO.

Contact angles of MARLIPAL 24 grades on hard surfaces

Sessile drop method, 1 g/l in D.I. water, 25° C, 50% humidity

The optimum cleaning performance on hard surfaces requires a balanced performance in wetting for ease of cleaning and emulsification properties to avoid dirt redeposition. The MARLIPAL 24 grades with medium EO chain length offer the required performance profile for cleaning.

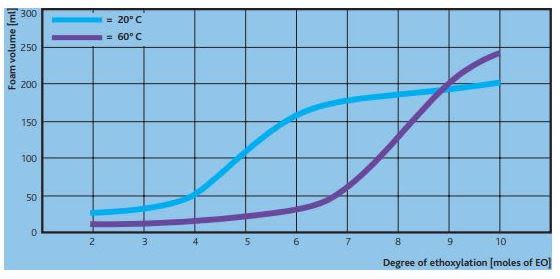

Foaming Profile

The MARLIPAL 24 ethoxylates are moderately foaming surfactants. The foaming profile has been determined by the Schlag foam method (DIN EN 12728) and is shown in the figure below. The foaming profile is well within the typical range of fatty alcohol ethoxylates.

Foaming profile

Schlagfoam method 1 g/l in D.I. water, 20° C and 60° C

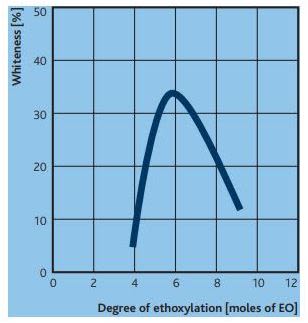

Detergency On Textiles

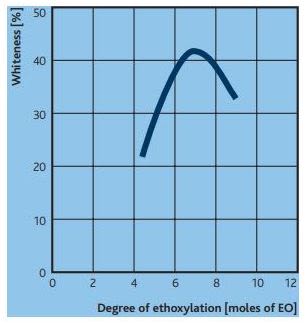

The MARLIPAL 24 surfactants have excellent detergency properties both on synthetic and natural fabrics. The detergency performance was determined in Linitest laboratory washing machines with pigment/sebum soiling. The ethoxylates with 6-7 EO showed an optimum in detergency performance.

Detergency on polyester fabrics at 30°C

Detergency on cotton fabrics at 60°C

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Bath & Shower Applications

- Fluids & Lubricants End Use

- Hair Care Applications

- Home Care Applications

- I&I Cleaning Applications

- Formulation Guidelines

For the formulator, MARLIPAL 24 ethoxylates are versatile building blocks for detergent compositions. By combining with other surfactants, e.g. anionics or cationics, it is possible to achieve synergistic and performance enhancing effects. It is advantageous that the MARLIPAL ethoxylates have a good hard water stability and are chemically stable over a wide pH range both in an acidic and in an alkaline medium.

A major application is in laundry powders and liquid detergents. In European laundry liquids (HDL) alcohol ethoxylates typically are present with 10–25%.

In all-purpose and bathroom cleaners ethoxylates are used as primary surfactants due to excellent grease removal properties and the moderate foam level when compared to anionics.

Properties

- Physical Form

- Appearance

- Clear to turbid liquid

- Miscible In

- Water

- Typical Properties

- Solubility In Water And Gel Formation

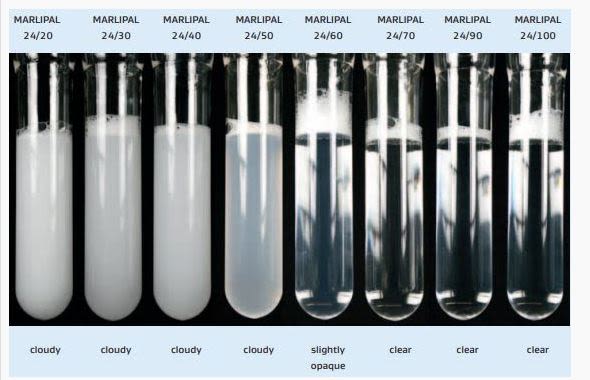

Solubility In Water

The solubility of the MARLIPAL 24 alcohol ethoxylates is determined by the chain length of the water soluble ether chain. Accordingly the solubility increases with increased degree of ethoxylation.

The solubility behavior of MARLIPAL 24 surfactants in dilute, aqueous solutions is shown in the photo below.

Gel Formation With Water

Mixtures of water and alcohol ethoxylates like the MARLIPAL 24 surfactants can cover a wide range of viscosities from free flowing liquids to solid gels depending on the amount of water added. The viscosity profile of MARLIPAL 24 grades is shown in the table. At very high surfactant concentrations (10% water) and at relatively low concentrations below approximately 30% surfactant (70% water), the mixtures of the higher ethoxylates are homogeneous and clear. In the middle concentration range, on the other hand, the MARLIPAL 24 products form pastes or gels which may be clear or cloudy.

MARLIPAL 0% water 10% water 20% water 30% water 40% water 50% water 60% water 70% water 80% water 90% water 24 /20 Liquid Liquid Paste

Paste Paste Paste Paste Paste Paste Liquid 24 /30 Liquid Liquid Gel Gel Gel Gel Gel Liquid Liquid Liquid 24 /40 Liquid Liquid Gel Gel Gel Gel Gel Gel Liquid Liquid 24 /50 Liquid Liquid Gel Gel Gel Gel Gel Liquid Liquid Liquid 24 /60 Liquid Liquid Gel Gel Gel Gel Gel Liquid Liquid Liquid 24 /70 Liquid Liquid Gel Gel Gel Gel Gel Liquid Liquid Liquid 24 /100 Solid Liquid Liquid Gel Gel Gel Gel Liquid Liquid Liquid - Surface Activity

One of the most characteristic properties of surface active agents like the MARLIPAL 24 ethoxylates is their ability to reduce the surface tension of water. The MARLIPAL 24 ethoxylates provide an excellent surface tension reduction already at low concentrations. Adding MARLIPAL 24 ethoxylates the surface tension of water of 72 mN/m can be reduced to values below 30 mN/m. The table gives the surface activity at different concentrations in an aqueous solution.

Surface tension (in mN/m, at 25° C in D.I. water)

MARLIPAL Surfactant concentration in 0.01 g/l Surfactant concentration in 0.1 g/l Surfactant concentration in 1.0 g/l 24/30 28.0* 26.0* 25.5* 24/40 28.5* 26.5* 26.5* 24/50 29.0* 26.5* 26.5* 24/60 29.5* 26.5* 26.5* 24/70 30.0 28.0 28.0 24/100 35.5 33.5 33.5 * Turbid solution, may lead to less accurate results

Ring method according to DIN EN 14370Critical Micelle Concentration

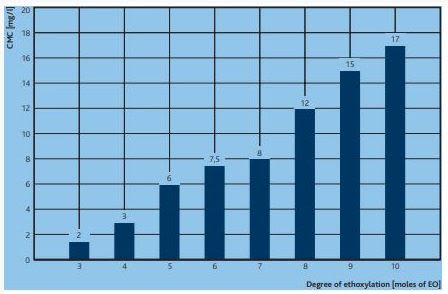

The critical micelle concentration (CMC) is a further characteristic property of a surfactant. The CMC is the concentration at which single surfactant molecules start to build micellar aggregates. The MARLIPAL 24 surfactants show CMC values from 2 mg/l up to values around 20 mg/l. The diagram below shows that the CMC increases in dependence to the ether chain length and increasing water solubility.

CMC in dependence to the ether chain length

| Value | Units | Test Method / Conditions | |

| Cloud Point (10 % in 25% butyl diglycol solution) | 66-68 | °C | DIN EN 1890 |

| pH (2 % in fully demin. water) | 5-7 | - | DIN EN 1262 |

| Density at 50°C | approx. 0.93 | g/ml | DIN 51757 |

| Water Content | max. 0.5 | % | — |

| Color (APHA) | max. 100 | - | AOCS Td 1b-64 |

| Setting Point | approx. 4 | °C | DIN ISO 3841 |

| Polyethylene Glycol Content | max. 2 | % mass | HPLC |

| Refractive Index | approx. 1.442 | - | DGF C - IV 5 |

| Ignition Temperature | approx. 305 | °C | DIN 51794 |

| Flash Point | approx. 168 | °C | ASTM D 92 |

Regulatory & Compliance

- Chemical Inventories

- Purity

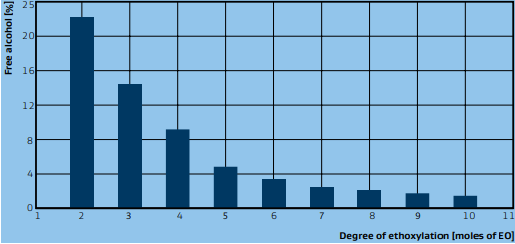

The MARLIPAL 24 products have a high active content of fatty alcohol polyethylene glycol ethers. Depending on the degree of ethoxylation, the products also contain varying amounts of the starting fatty alcohol.

Content of free alcohol in MARLIPAL 24 products

The water content of the MARLIPAL 24 products is usually less than 0.5%.

Technical Details & Test Data

- Viscosities

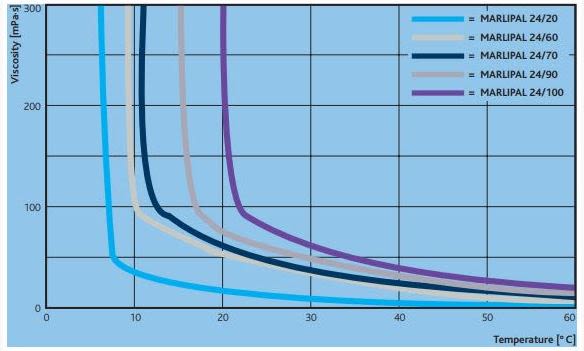

The ethoxylates of the MARLIPAL 24 series with short EO chains are liquid with low viscosity at room temperature. Within this product series the viscosity increases continuously with increasing degree of ethoxylation.

The temperature dependent viscosity at a constant shear rate is shown in the diagram. The viscosity of the water free MARLIPAL 24 ethoxylates increases rapidly at lower temperatures.

Temperature vs. viscosity at a shear rate of D=10 1/s

Rotary viscometer with plate-plate geometry according to DIN 53018- Cloud Points

The cloud point is a leading parameter for characterizing nonionic surfactants and can be determined by a simple test method, described e.g. in DIN EN 1890.

The temperature, at which this clouding occurs, is specific for each ethoxylate and is referred to as the cloud point of the surfactant. The cloud point is a function of the surfactant concentration and is usually determined using 1% or 2% surfactant solutions. If the ethoxylate is insoluble or only sparingly soluble in water, the cloud point can also be determined in aqueous butyl diglycol solution.

The cloud points of MARLIPAL 24 products are listed in the table.

MARLIPAL 10% in 25% (butyldiglycol solution) 5g + 25g of 25% (butyldiglycol solution) 1% in D.I. water 2% in D.I. water 2% in 10% Nacl solution 1% in 5% Nacl solution 24/20 49-51 ca. 37 - - - - 24/30 59-61 ca. 51 - - - - 24/40 66-68 ca. 62 - - - - 24/50 72-74 ca. 70 ca. 22 ca. 21 - - 24/60 76-78 ca. 75 ca. 42 ca. 42 ca. 22 ca. 31 24/70 ca. 79 ca. 78 ca. 54 53-56 ca. 33 ca. 43 24/79 ca. 79 ca. 78 ca. 54 53-56 ca. 33 ca. 43 24/99 ca. 84 ca. 84 ca. 82 81-83 ca. 54 ca. 65 24/100 ca. 86 ca. 86 ca. 94 ca. 94 ca. 64 ca. 78

Packaging & Availability

- Country Availability

- Regional Availability

- Packaging Information

Road tankers

Storage & Handling

- Storage and Handling

- Stored in Stainless steel vessels (Steel No: 1.4541 or 1.4571)

- The effects of extreme temperatures (cold, heat) may cause the product to become turbid, viscous, congeal or separate. In such cases mixing at 30°C-40°C will restore the product for use.

Precautions for safe handling

Advice on safe handling

- Wear personal protective equipment.

- Avoid contact with skin and eyes.

Advice on protection against fire and explosion

- Normal measures for preventive fire protection.

- Do not spray on a naked flame or any incandescent material

Fire-fighting class

- B: Fires involving liquids or liquid containing substances. Also includes substances which become liquid at elevated temperatures.

Conditions for safe storage, including any incompatibilities

Requirements for storage areas and containers

- Keep tightly closed in a dry and cool place

Other data

- Stable at normal ambient temperature and pressure.