Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- INCI Name

- Ingredient Origin

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- CAS No.

- 69011-36-5

- EC No.

- 500-241-6

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

Properties

- Physical Form

- Appearance

- Clear to turbid liquid

- Insoluble in

- Water

- Typical Properties

- Solubility and Gel Formation With Water

Since the polyethylene glycol ether chain is the watersoluble constituent of MARLIPAL O13 surfactants, the solubility in water increases with increasing degree of ethoxylation. The lower ethoxylates (3-6 mol EO), in which the alkyl group predominates as the hydrophobic component, are accordingly only sparingly soluble in water. They do, however, dissolve in nonpolar organic solvents and are used for example as w/o-emulsifiers. In contrast, the higher ethoxylates are readily soluble in water.

Alkylpolyethylene glycol ethers, the MARLIPAL O13 ethoxylates form free-flowing or solid gels when water is added in certain concentration ranges. During the preparation of cleaning formulations, this tendency to gel can have an adverse effect on processing. To prevent lumping and gelling, it is thus advisable to add the nonionic surfactant to the water, use warm water and stir well.

Marlipal 0% water 10% water 20% water 30% water 40% water 50% water 60% water 70 % water 80% water 90% water O 13/30 Cloudy Liquid Clear Liquid Clear Liquid Cloudy, non-homogenous Cloudy, non-homogenous Cloudy, non-homogenous Cloudy, non-homogenous Cloudy, non-homogenous Cloudy, non-homogenous Cloudy, non-homogenous O 13/40 Cloudy Liquid Clear Liquid Clear Liquid Gel or Paste Gel or Paste Gel or Paste Gel or Paste Gel or Paste Cloudy, non-homogenous Cloudy, non-homogenous O 13/50 Cloudy Liquid Clear Liquid Clear Liquid Gel or Paste Gel or Paste Gel or Paste Gel or Paste Gel or Paste Gel or Paste Cloudy, non-homogenous O 13/60 Cloudy Liquid Clear Liquid Gel or Paste Gel or Paste Gel or Paste Gel or Paste Gel or Paste Gel or Paste Gel or Paste Cloudy, non-homogenous O 13/70 Cloudy Liquid Clear Liquid Gel or Paste Gel or Paste Gel or Paste Gel or Paste Cloudy, non-homogenous Cloudy, non-homogenous Cloudy, non-homogenous Cloudy, non-homogenous O 13/80 Cloudy Liquid Clear Liquid Gel or Paste Gel or Paste Gel or Paste Gel or Paste Clear Liquid Clear Liquid Clear Liquid Clear Liquid O 13/90 Cloudy Liquid Clear Liquid Gel or Paste Gel or Paste Gel or Paste Gel or Paste Gel or Paste Clear Liquid Clear Liquid Clear Liquid O 13/100 Solid Clear Liquid Clear Liquid Gel or Paste Gel or Paste Gel or Paste Gel or Paste Clear Liquid Clear Liquid Clear Liquid O 13/120 Solid Clear Liquid Clear Liquid Clear Liquid Gel or Paste Gel or Paste Gel or Paste Clear Liquid Clear Liquid Clear Liquid This shows the physical states of aqueous mixtures of MARLIPAL O13 grades. At very high surfactant concentrations (10 % water) and at relatively low concentrations below approximately 30 % surfactant (70 % water), the mixtures of the higher ethoxylates are homogeneous and clear. In the medium concentration range, on the other hand, the MARLIPAL O13 products form pastes or gels which may be clear or cloudy.

| Value | Units | Test Method / Conditions | |

| Cloud Point (10 % in 25% butyl diglycol solution) | 58-61 | °C | DIN EN 1890 |

| pH (2 % in fully demin. water) | 5-7 | - | DIN EN 1262 |

| Density at 50°C | approx. 0.92 | g/ml | DIN EN ISO 3838 |

| Viscosity at 50°C (Brookfield) | approx. 18 | mPa.s | DIN ISO 2555 |

| Water Content | max. 0.5 | % | — |

| Flash Point | min. 150 | °C | — |

| Iodine Color Number | max. 2 | mg I/100 ml | DIN EN 1557 |

| Refractive Index | approx. 1.446 | - | DGF C - IV 5 |

| Polyethylene Glycol Content | max. 2.0 | % mass | HPLC |

| Setting Point | max.-10 | °C | DIN ISO 3841 |

| Ignition Temperature | approx. 340 | °C | DIN 51794 |

Regulatory & Compliance

Technical Details & Test Data

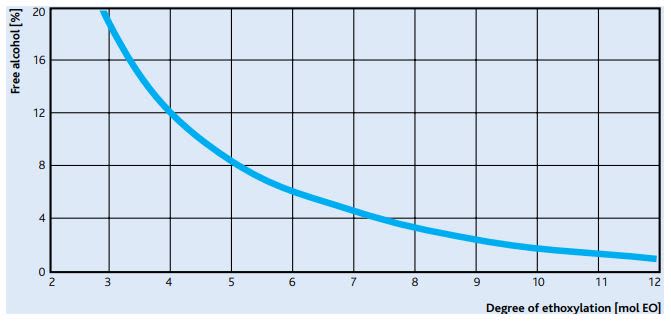

- Free Alcohol Content

Purity

The MARLIPAL O13 products have a high active content of alkylpolyglycol ethers. Depending on the degree of ethoxylation, the products also contain varying amounts of the starting material isotridecanol. The free alcohol, the proportion of which decreases with increasing degree of ethoxylation supports the cleaning action of the ethoxylates and contributes to foam regulation.

During the ethoxylation, secondary reactions yield polyethylene glycols having the structure H(OCH2CH2) nOH. The proportion of polyethylene glycols having varying chain lengths is below 2 %. Polyethylene glycols are water-soluble products which do not impair the properties of the nonionic surfactants.

To neutralize the alkaline catalyst required for the ethoxylation reaction, MARLIPAL O13 grades are treated with shortchain organic acids (usually acetic acid or lactic acid) and adjusted to a pH of 5–7 (2 % in water). Accordingly, they contain a small amount of organic salt and small amounts (less than 0.5 %) of water. The water content, however, may increase on exposure to air since ethoxylates are hygroscopic.

- Wetting Efficiency

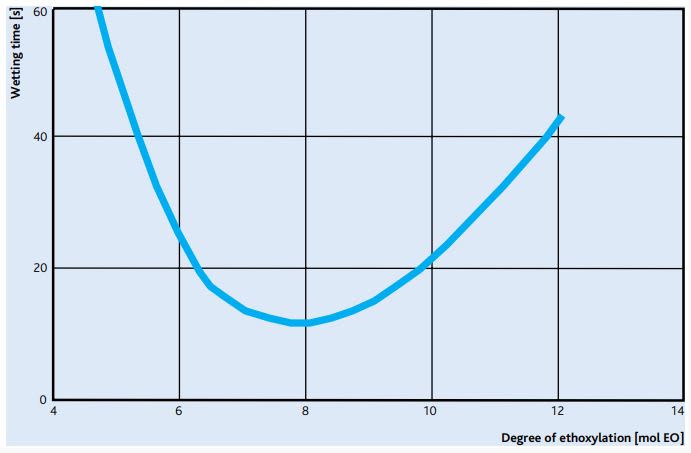

Wetting Efficiency on Textiles:

Wetting efficiency on cotton as a function of degree of ethoxylation (1 g/l in demin. water, 20 °C)

In detergents, the surfactants are the active force which removes grease, soiling and pigment particles from the fibers. The wetting efficiency on textiles is therefore an important criterion for assessing the performance of a surfactant. The products of the MARLIPAL O13 series have high wetting efficiency on textiles, the best values being observed for MARLIPAL O13/60 to MARLIPAL O13/100. The wetting effect, which, in accordance with DIN EN 1772, corresponds to the time taken for a cotton disk to sink, is shown in Figure 3 as a function of the degree of ethoxylation. The shorter the sinking time, the better the wetting efficiency.In detergents, the surfactants are the active force which removes grease, soiling and pigment particles from the fibers. The wetting efficiency on textiles is therefore an important criterion for assessing the performance of a surfactant. The products of the MARLIPAL O13 series have high wetting efficiency on textiles, the best values being observed for MARLIPAL O13/60 to MARLIPAL O13/100. The wetting effect, which, in accordance with DIN EN 1772, corresponds to the time taken for a cotton disk to sink, is shown in Figure 3 as a function of the degree of ethoxylation. The shorter the sinking time, the better the wetting efficiency.

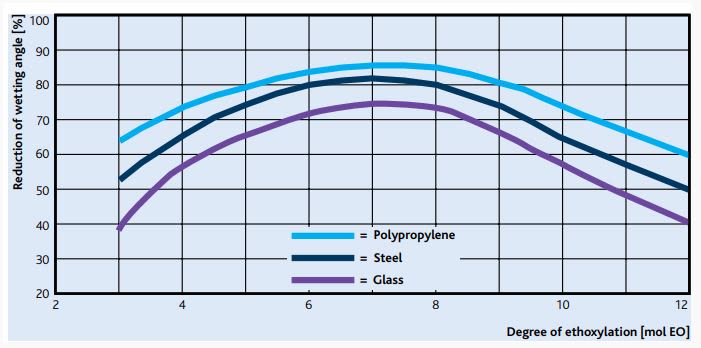

Wetting efficiency on hard surfaces:

Wetting efficiency on hard surfaces as a function of degree of ethoxylation (1 g/l in demin. water, 25 °C)

The wetting behavior of surfactant solutions on hard surfaces, such as glass, ceramics, steel and plastics, can be assessed by wetting angle investigations. Good wetting on hard surfaces can be recognized from how much the shape of the droplet of a surfactant-containing aqueous droplet, traced onto the surface of the material, deviates from the shape of a droplet of pure water. The parameter measured is the wetting angle of the droplet. A high reduction of the wetting angle corresponds to good wetting properties on a given substrate . Polypropylene and steel are wetted very well, the optimum range being from 6-8 mol of ethylene oxide per mol alcohol.

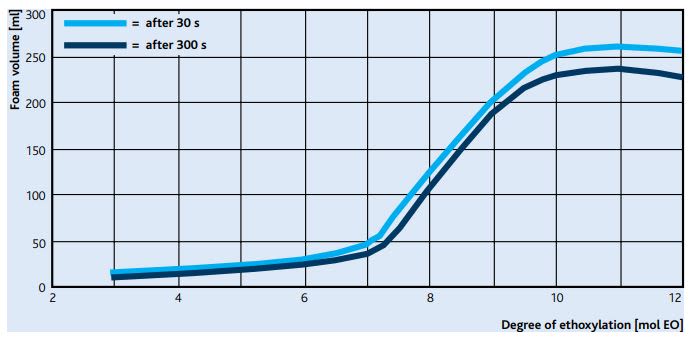

- Foaming Profile

Foaming profile in accordance with DIN EN 12728 (1 g/l in demin. water, 20 °C)

Like all nonionic surfactants, the MARLIPAL O13 ethoxylates produce less foam than anionic products. The foaming profile of the MARLIPAL O13 surfactants is shown in graph and has been determined by the Schlag foam method (DIN EN 12728). The MARLIPAL O13 products containing 8-12 mol of EO/mol produce foam volumes of 100-250 ml in the test, whereas the short chain product grades with lower solubility in water produce significantly less foam. The foaming profile is well within the typical range of alcohol ethoxylates. In comparison, an anionic surfactant such as linear alkylbenzene sulphonate (LAS) produces a foam volume of ca. 600 ml.

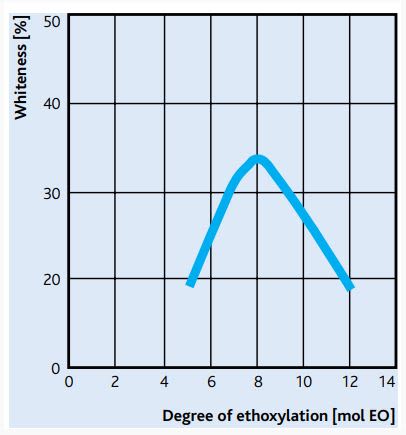

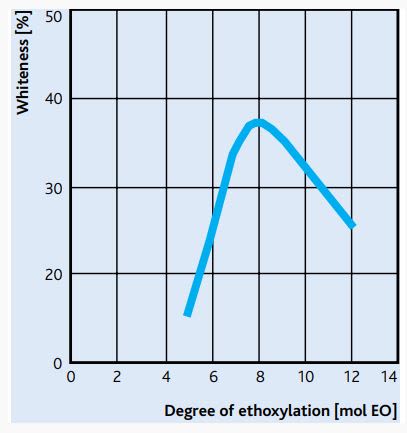

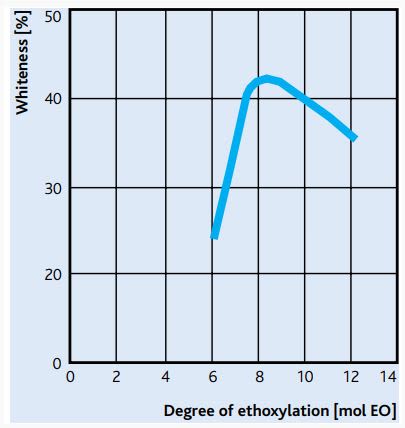

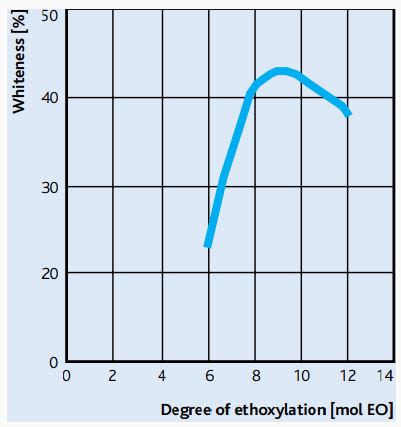

- Detergency on Textiles

The MARLIPAL O13 surfactants have excellent detergency performance both on synthetic and on natural fabrics. The performance on polyester, cotton/polyester blend and cotton was investigated. There are optima in the detergency in the range from 6-10 mol EO, which shift to higher degrees of ethoxylation at a higher washing temperature.

Detergency on polyester at 30 °C

Detergency on cotton/polyester blend at 60 °C

Detergency on cotton at 60 °C

Detergency on cotton at 90 °C

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Storage and Handling

Precautions for safe handling

Advice on safe handling

- Wear personal protective equipment.

- Avoid contact with skin and eyes.

- The effects of extreme temperatures (cold, heat) may cause the product to become turbid, viscous, congeal or separate. In such cases mixing at normal temperatures (i.e. room temperature) will restore the product for use.

Advice on protection against fire and explosion

- Normal measures for preventive fire protection.

- Do not spray on a naked flame or any incandescent material.

Fire-fighting class

- B: Fires involving liquids or liquid containing substances. Also includes substances which become liquid at elevated temperatures.

Conditions for safe storage, including any incompatibilities

Requirements for storage areas and containers

- Keep tightly closed in a dry and cool place.

Storage class (TRGS 510)

- 10: Combustible liquids not in Storage Class 3

Other data

- Stable at normal ambient temperature and pressure.

- Road tankers, about 950 kg containers, about 190 kg iron drums

- Stainless steel vessels (Steel no: 1.4541 or 1.4571)