Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- INCI Name

- Ingredient Origin

- Agrochemical Functions

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- HII Features

Applications & Uses

- Applications

- Applicable Processes

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

Properties

- Physical Form

- Soluble in

- Water (2 wt. %)

- Typical Properties

- Solubility and Gel Formation With Water

Solubility

The solubility of the SAFOL 23E ethoxylates is determined by the chain length of the water soluble polyethylene glycol ether chain. Accordingly, the solubility increases at a higher degree of ethoxylation. Lower ethoxylates , e.g. SAFOL 23E3, are only sparingly soluble in water as these molecules are dominated by the hydrophobic alcohol part. SAFOL 23E3 is soluble in non-polar organic solvents and can be applied as emulsifier.

Gel formation with water

The gel phases typically occur at medium concentrations and can have significant stability even when additional water is added.

Product 0% water 10% water 20% water 30% water 40% water 50% water 60% water 70% water 80% water 90% water SAFOL 23E3 Liquid Liquid Liquid Gel or paste Gel or paste Gel or paste Gel or paste Gel or paste Cloudy Liquid Cloudy Liquid SAFOL 23E5 Liquid Liquid Gel or paste Gel or paste Gel or paste Gel or paste Gel or paste Gel or paste Cloudy Liquid Cloudy Liquid SAFOL 23E6.5 Liquid Liquid Gel or paste Gel or paste Gel or paste Gel or paste Gel or paste Liquid Liquid Liquid SAFOL 23E7 Liquid Liquid Gel or paste Gel or paste Gel or paste Gel or paste Gel or paste Liquid Liquid Liquid SAFOL 23E9 Cloudy Liquid Liquid Liquid Liquid Gel or paste Gel or paste Gel or paste Liquid Liquid Liquid The diagram, which is only intended as a guide to possible physical states on mixing with water, shows that the addition of 10 % of water to the SAFOL 23E grades always gives a homogenous and clear product. This fact is taken into account in our sale products SAFOL 23E7-90 % and SAFOL 23E9-90 %.

- Surface Active Property

One of the most characteristic properties of surface active agents is their ability to reduce the surface tension of water. The SAFOL 23 ethoxylates provide an excellent surface tension reduction already at low concentrations. By adding SAFOL 23 ethoxylates the water surface tension of 72 mN/m can be reduced to values below 30 mN/m. Table 8 illustrates the surface activity at different surfactant concentrations in aqueous solution.

The Critical Micelle Concentration (CMC) is a further characteristic property of a surfactant. The CMC is the concentration at which single surfactant molecules start to build micellar aggregates.

Surface tension in mN/m at 25 °C in D.I. water Critical micelle concentration (CMC) Surfactant Concentration 0.01 g/l 0.1 g/l 1.0g/l mg/l SAFOL 23E3 26.5 * 26.5 * 27 * 6 SAFOL 23E5 29 * 27.5 * 27.5 * 13 SAFOL 23E6.5 32 27.5 28 18 SAFOL 23E7 32 28 28.5 18 SAFOL 23E9 36.5 30.5 31 32

| Value | Units | Test Method / Conditions | |

| Average Molecular Weight | 324.0 | g/mol | — |

| Average Ethylene Oxide Content | 40.7 | wt. % | — |

| Free Ethylene Oxide Content | max. 1 | ppm | — |

| 1,4-Dioxane Content | max. 1 | ppm | — |

| Glycol Content | max. 2 | wt. % | — |

| Cloud Point (10% in BDG) | 59 - 60 | °C | — |

| Free Alcohol Content | max. 13 | wt. % | — |

| Density (at 40°C) | 0.92 | g/mL | — |

| HLB (Calculated) | 8.1 | — | — |

| Viscosity (at 40°C) | 16.5 | cSt | — |

| pH (5 % in IPA/water) | 6 - 8 | — | — |

| Wettability on Cotton | 94.0 | sec | — |

| Surface Tension (SFT) | 26.1 | mN/m | — |

| Average Contact Angle on PTFE | 36.63 | — | — |

| Critical Micelle Concentration | 13.29 | mg/L | — |

| Pour Point | -12.0 | °C | — |

| Water Content | max. 0.1 | wt. % | — |

| Color | max. 50 | mg Pt/L | APHA |

| Flash Point | 154.0 | °C | — |

| Hydroxyl Number | 168 - 176 | mg KOH/g | — |

Regulatory & Compliance

Technical Details & Test Data

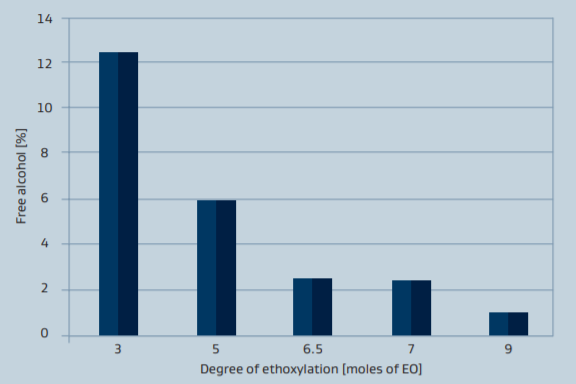

- Free Alcohol Content

Purity

SAFOL 23E products have a high active content of fatty alcohol polyethylene glycol ethers. Depending on the degree of ethoxylation, the products also contain varying amounts of starting alcohol. The free fatty alcohol, the portion of which decreases with increasing degree of ethoxylation, supports the cleaning action of the ethoxylates and contributes to foam regulation.

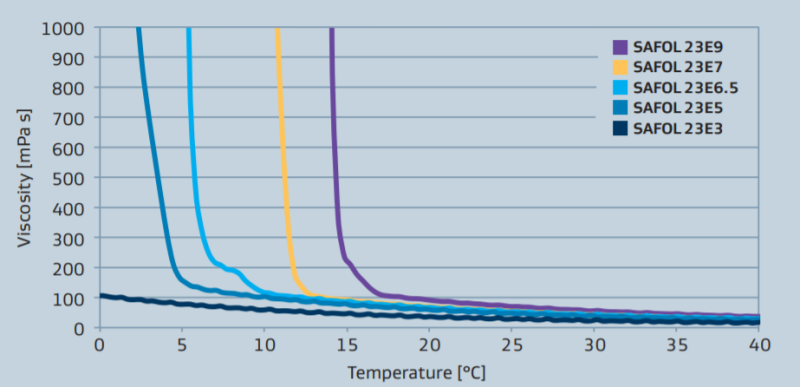

- Viscosity vs Temperature

Viscosity as a function of temperature Rotary viscometer in plate-plate geometry according to DIN 53018, shear rate D=10 1/s

The viscosity profile of alcohol ethoxylates is important for transport and storage issues. The ethoxylates of the SAFOL 23E series with short EO chains are liquid with low viscosity at room temperature. Within the product series the viscosity increases continuously with increasing degree of ethoxylation. Viscosities measured at 20 °C and 50 °C according to Brookfield method . Viscosity was also determined over a range of temperatures. Temperature dependent viscosity of the SAFOL 23 ethoxylates is shown in Figure 5 (determined at a constant shear rate). The viscosity of the ethoxylates increases rapidly at lower temperatures. The product grades SAFOL 23E7-90 % and SAFOL 23E9-90 % contain ca. 10 % water and are homogeneous clear liquids at room temperature.

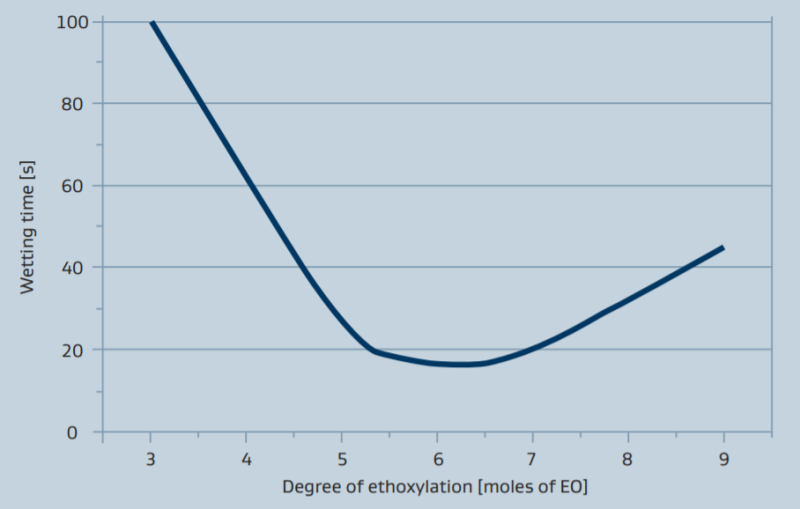

- Wetting Efficiency

Wetting efficiency on textiles

The wetting times of the SAFOL 23E products were determined in aqueous solutions on cotton fabrics. The wetting performance, which corresponds to the time taken for a cotton disk to sink in aqueous solution, is a function of the degree of ethoxylation. The shorter the sinking time, the better the wetting efficiency

The SAFOL 23 ethoxylates provide excellent wetting power on textiles, the best values being observed for SAFOL 23E5 to SAFOL 23E7

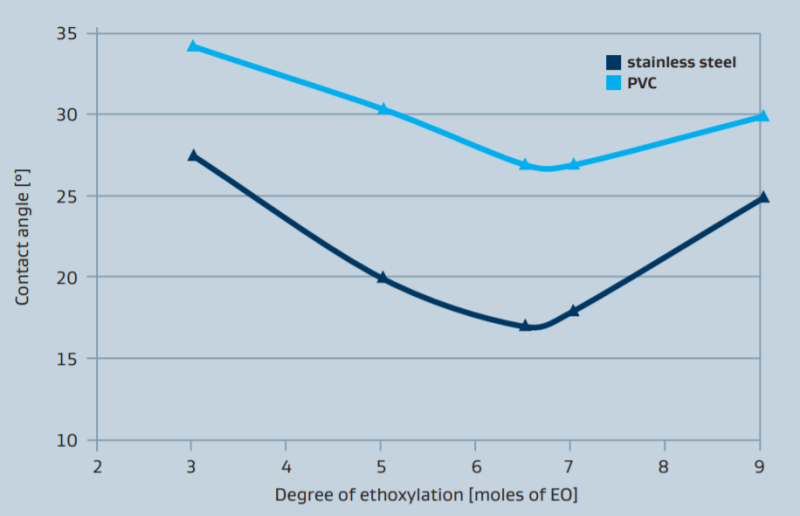

Wetting efficiency on hard surfaces

The wetting performance on hard surfaces such as metal or plastics can be assessed by contact angle measurements. The contact angle indicates how far a droplet of a surfactant solution spreads on the given surface. The lower the contact angle the better the wetting efficiency on the surface.

The contact angles of SAFOL 23E surfactants dissolved in water at a concentration of 1 g/l are displayed on different surfaces. The best wetting performance is found for the SAFOL 23E ethoxylates with 6.5 to 7 moles EO.

- Foaming Profile

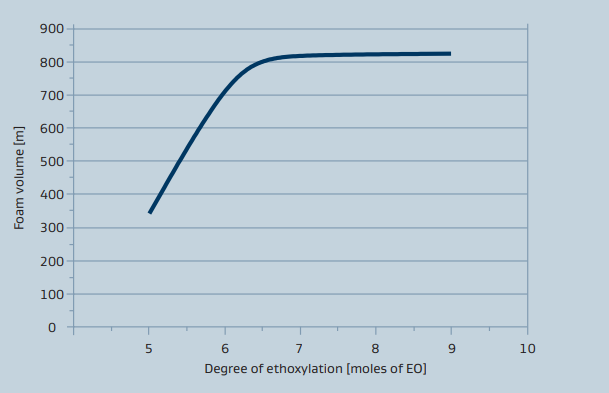

Foaming profile SITA foam method, 1 g/l in D.I. water, 20 °C

SAFOL 23E ethoxylates are moderately foaming surfactants. Figure 11 shows the foaming profile determined by the SITA Foam method (foam generated by a rotating disk). At room temperature the foam level of the ethoxylates increases with increasing degree of ethoxylation. When compared to the market standards, the SAFOL 23E foaming profile is well within the typical range for fatty alcohol ethoxylates.

Packaging & Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Shelf Life

- 24 Months

- Storage And Handling

Safe handling advice

- Take precautionary measures against static discharges.

Storage/Transport pressure

- Ambient

Load/Unload temperature

- 15-38 °C (60-100 °F)

Storage and handling materials

- Suitable: Carbon steel coated with baked phenolic. Any moisture may cause rusting of carbon steel. If product is moisture free, uncoated carbon steel tanks.

Further information on storage conditions

- Mix thoroughly before use. When stored in the liquid form, ethoxylates should be padded with a dry inert gas, such as nitrogen, to prevent oxygen or air from entering the tank. Prolonged storage in the presence of air or oxygen may cause product degradation. Oxidation is not expected when stored under a nitrogen atmosphere. Inert gas blanket and breathing system needed to maintain color stability. Use dry inert gas having at least -40°C (-40°F) dew point.

- Small quantities should be stored in sealed bottles, totes and drums at a temperature of 25°C (77°F) or less. Liquid bulk quantities should be padded with a dry inert gas, such as nitrogen, to prevent air from entering the tank or container. The product should not be exposed to temperatures in excess of 60°C (140°F) for long periods of time to avoid product degradation. Based on our experience, SAFOL 23E3 Ethoxylate shows no physical and/or chemical changes for at least 24 months after the manufacturing date when stored under conditions that minimize exposure to air, moisture and extreme temperatures. It is recommended to test the ethoxylate for key specifications every 24 months after the manufacturing date.