Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CAS No.

- 593-45-3

- EC No.

- 209-790-3

Features & Benefits

- Labeling Claims

- Performance Profile

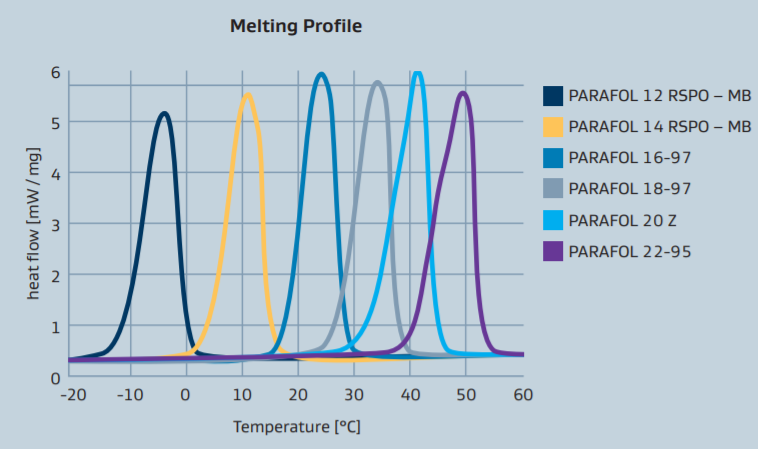

DSC thermogram - melting profile

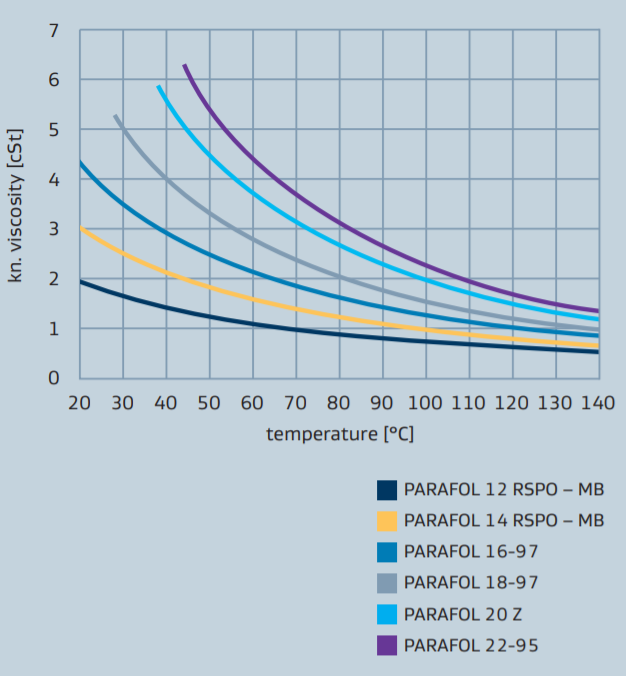

The kinematic viscosity is the resistance to flow of a fluid under gravity. It is determined by measuring the time for a volume of liquid to flow under gravity through a calibrated glass capillary viscometer.

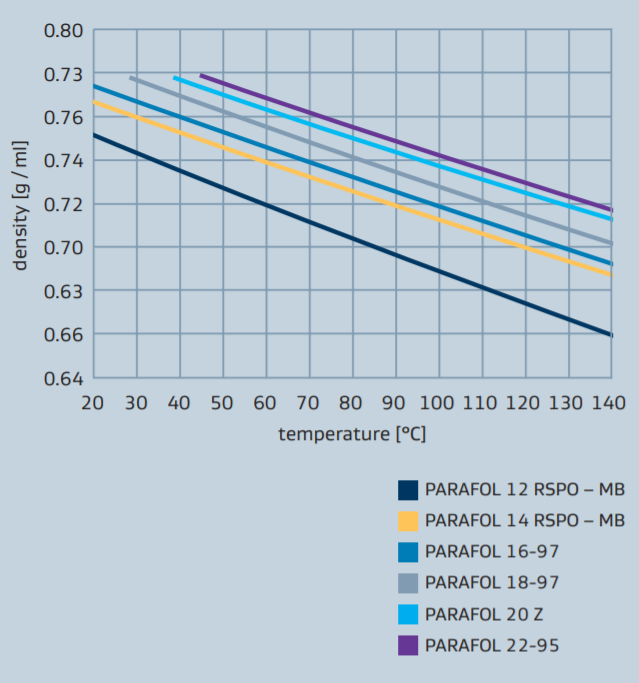

Density is a measure of how much mass is contained in a given unit volume. The formal definition of density is mass per unit volume. Usually the density is expressed in grams per mL. In general,

density can be changed by changing either the pressure or the temperature. Increasing the pressure will always increase the density of a material. Increasing the temperature generally decreases the density, but there are notable exceptions to this generalization.PARAFOL density vs. temperature

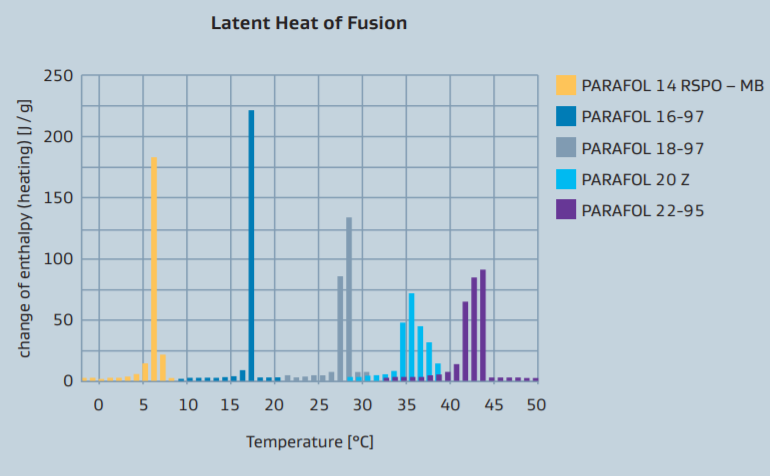

Detailed DSC measurement in intervals of 1°C

Applications & Uses

- Markets

- Applications

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

Properties

- Physical Form

- Odor

- Odorless

- Appearance

- Colorless after melting

- Insoluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| nC16-AN | max. 1.0 | wt. % | 850-14 |

| iC18-AN | max. 1.5 | wt. % | 850-14 |

| nC18-AN | min. 97.0 | wt. % | 850-14 |

| nC 20-AN | max. 1.0 | wt. % | 850-14 |

| Total Paraffins Content | min. 98.0 | wt. % | 850-14 |

| Onset of meltinglinie | min. 26 - 29 | °C | DIN 53765 |

| Heat of fusion | min. 220 | — | DIN 53765 |

| Density (40°C) | approx. 0.768 | g/ml | DIN 51757 |

| Melting point | approx. 28 | °C | 600-22c |

| Flash point | approx. 154 | °C | DIN EN ISO 2719 |

| Refractive index (40°C) | 1.430 - 1.432 | — | DIN 51423 |

| Viscosity (40°C) | approx. 3.1 | mPas | 600-25 |

Regulatory & Compliance

Storage & Handling

- Storage And Handling

PARAFOL single cut paraffns are an excellent choice when looking for a phase change material for latent heat storage applications including functional textiles and construction. The performance profile of PARAFOL single cut paraffin is characterized by:

- Sharp melting profiles.

- Adjustable melting points by chain length in the desired temperature range.

- High latent heat of fusion.

- Non-tendency to segregation.

- Chemical inertness.

- Non-corrosiveness to conventional storage and construction material.

- Non-degradation throughout melt/freeze cycles.

- Non-tendency to supercooling.

Precautions for safe handling

Advice on safe handling

- Wear personal protective equipment.

- Avoid contact with skin and eyes.

Storage temperature of all goods shipped in barrels or drums.

5<T<30°C

41<T<86°F