Knowde Enhanced TDS

Identification & Functionality

- Backing Material Type

- Product Type

- Technologies

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

- Dry/glue-free/non-tacky

- Residue-free removal

- Reusable

- Customizable adhesive strength (0-40 N/cm2 shear & 0-2 N/cm2 peel)

- Directional adhesion or friction performance may be possible for select applications

- Available in sheets, die cut pieces & double-sided microstructure tape

- Maximum sheet size is 8”x16”; custom sheets available in smaller sizes

- Microstructures range from 10-150μm in height & 10-150μm in diameter

- Application temperature range of -20°C to 100°C

- Adhesive Performance

5lb pre-load, 1 minute dwell time, retraction speed of 1mm/s, on stainless steel substrate.

- Benefits

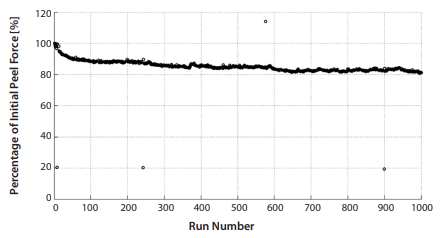

- Repeatability: Setex Tape provides repeatable adhesive performance, unlike PSAs that lose their strength over time.

- Residue-Free: Setex Tape does not leave any sticky adhesive residues when it is removed from a surface.

- Dry / Glue-free / Non-tacky: Setex Tape is completely dry, providing exceptionally strong adhesion without sticky chemical bonds or lint-attracting hooks (or mushrooms).

- Customizable Performance: Setex Tape can be designed with varying shear and peel strengths to fit your application’s needs.

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Guidelines and Recommendations

- Setex Tape is supplied with fiber tips in contact with a release film. This film should be removed before evaluation of the samples and replaced when samples are not in use.

- For best performance, adhesive samples should be applied to a clean, dry surface, free ofany oil ordebris.

- The strength of the dry adhesive is dependent onthe number of microfiber tips in contact withthe surface and the contact time. We recommend applying with firm pressure to achieve good surface contact.

- For optimal adhesive strength avoid touching the microfiber surface. We recommend handling the microfiber samples using gloves to avoid contamination.

- Carrier Options

- PET film

- TPU film

- Foam

- Pressure sensitive adhesive

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Shear Strength | 30-40 | N/cm2 | — |

| 180° Peel Strength | 2022-01-02 | N/cm | — |

| 90° Peel Strength | 0.6-0.8 | N/cm | — |

Technical Details & Test Data

- Performance over 1000 peel cycles

- Test Data

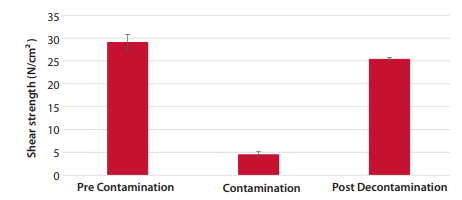

How to Clean Contaminated Microfibers

If the microfiber surface becomes contaminated, it can be cleaned. If contamination is mild (e.g., small amount of dust or debris), it can be refreshed by blotting with a low-medium tack pressure sensitive adhesive tape, such as Scotch® tape. The contaminant will stick to the tacky adhesive and lift off the microfiber surface. If the contamination consists of heavier amounts of debris, or if the microfiber surface is contaminated by skin oils, it can be refreshed by rinsing the surface with isopropyl alcohol (typically 70%) and wiping with a lint-free cloth. Allow to dry completely. For heaviest contaminants, the surface can be lightly cleaned with basic dish soap and water. Allow the surface to dry completely before reapplying the microfiber surface to the mating surface.

Setex was contaminated with ISO Grade 12103-1 A2 Fine Test Dust. The decontamination protocol used to remove the dust particles was to wash it thoroughly with liquid dish soap and water, then drying it under a high-speed air blower.