Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Cleaning Ingredients Functions

- Technologies

- Product Families

- Surfactant Type

Nonionic.

Features & Benefits

- Labeling Claims

- HII Features

- Biodegradability

BIO-SOFT LFS-07 is expected to be readily biodegradable based on the biodegradation profile of its major component(s).

- Product Benefits

- Preservative Free.

- Has degreasing property.

- Leave film-free and streak-free surface.

- Easy-to-Handle Liquids

- Dilutable

- Low Foam or Fast Foam Break

- Cost-Effective Performance

- Versatile, Multi-Surface Performance

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Applications

BIO-SOFT LFS-07 is a high active nonionic surfactant blend that can be used in a wide variety of cleaning applications due to its degreasing power.

- BIO-SOFT LFS-07 is designed for use on low- and high-SFE surfaces.

- This product is especially useful in cleaners used on surfaces where powerful cleaning combined with minimal filming/streaking is desired, such as glass windows and mirrors, floors, ceramic, and vehicle body and windows.

- BIO-SOFT LFS-07 can often replace alkyl polyglucoside surfactants in cleaners due to its excellent low film/streak performance.

- With BIO-SOFT LFS-07, a single cleaner can be formulated to work on all these surfaces and heavily soiled ones as well.

- BIO-SOFT LFS-07 is made to have a very low pour point for easy handling, remaining clear and fluid down to -15°C.

- BIO-SOFT LFS-07 is a highactive alkoxylates that can remove soil without leaving behind a noticeable residue.

Properties

- Physical Form

- Appearance

- Clear liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Activity | 90 - 100 | % | — |

| Actives Content | 90 | % | — |

| pH (in 1% Aqueous) | 10.5 | — | — |

| Color | max. 80 | — | Apha Scale |

| HLB | 11.9 | — | — |

| Viscosity (at 25°C, 77 °F) | 64 | cPs | — |

| Flash Point | min. 94 | °C | — |

| Cloud Point (in 1% Aqueous) | 34 | °C | — |

| Freeze Point | -15 | °C | — |

| Density | 1 | g/ml | — |

| Surface Tension (at CMC) | 27.1 | dynes/cm | — |

| Draves Wetting (in 1% Aqueous, at 25°C, 77 °F) | 4.3 | sec | — |

| Critical Micelle Concentration (CMC) | 300 | mg/L | — |

| Ross Miles Foam (Initial, 0.1% aqueous) | 7.9 | cm | — |

| Ross Miles Foam (5-min, 0.1% aqueous) | 3.3 | cm | — |

| Regulated Volatile Organic Chemicals (Ethanol) | 0 | % | U.S. EPA |

Regulatory & Compliance

- Chemical Inventories

- Clearances

The international inventories (country clearances) of BIO-SOFT LFS-07 can be found in Section 15 of the Safety Data Sheet (SDS). It is the responsibility of the formulator to review the chemical control regulations for each country where the end product is intended to be sold or used.

Technical Details & Test Data

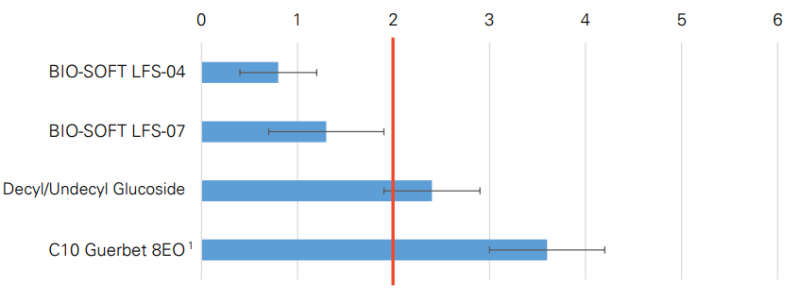

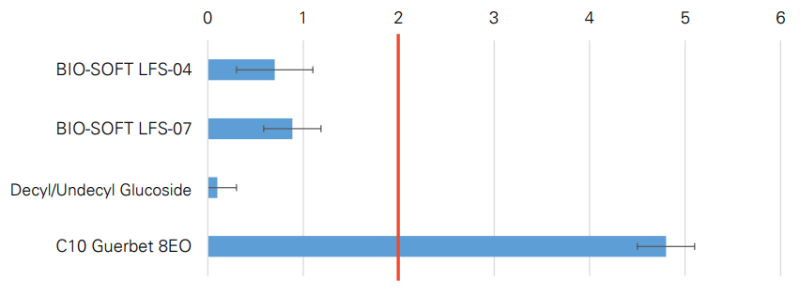

- BIO-SOFT® LFS-07 Film/Streak Performance

Stepan’s Low Film/Streak solutions, BIO-SOFT LFS-07 demonstrates strong film/streak performance on both low- and high-SFE surfaces. When compared to clean surfaces, the acrylic polished vinyl and ceramic treated with Stepan’s LFS-Series alkoxylates show no noticeable difference in filming and streaking between products.

Acrylic Polished Vinyl, Low SFE

Ceramic, High SFE

Method: SM250-A Application 001, pipet application, no-wipe, measured at 15 minutes.

Formulation: 0.1 wt% surfactant in tap water (140ppm nominal)

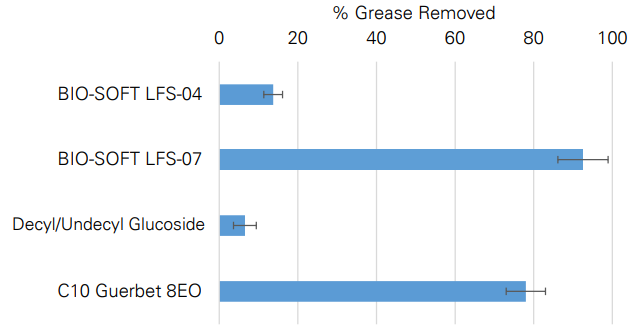

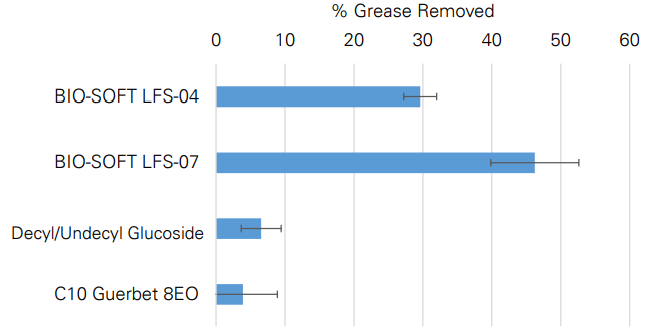

- BIO-SOFT® LFS-07 Cleaning Performance

Along with film/streak improvement, BIO-SOFT LFS-07 exhibit powerful cleaning performance. For everyday messes such as kitchen cleaning, BIO-SOFT LFS-07 provides superior performance.

Immersion Degreasing of Tough Grease

Method: Immersion degreasing, lithium grease/used motor oil (50/50 by wt%), stainless steel, 22°C, 1000 RPM, 30 min, gravimetric analysis. Higher numbers are better.

Formulation: 1 wt% surfactant, 1 wt% potassium hydroxide (45%), 1 wt% sodium metasilicate

Immersion Degreasing of Cooking Shortening

Method: Immersion degreasing, cooking shortening, stainless steel, 22°C, 1000 RPM, 30 min, gravimetric analysis. Higher numbers are better.

Formulation: 0.2 wt% surfactant in deionized water

Safety & Health

- Health Effects

BIO-SOFT LFS-07 is expected to be slightly toxic orally (LD₅₀ >500 mg/kg). Undiluted product is expected to be severely irritating to eyes, and may cause irreversible eye damage.

Packaging & Availability

- Packaging Type

- Standard Packaging

BIO-SOFT LFS-07 is available in drums.

Storage & Handling

- Storage & Handling

Normal safety precautions (e.g., gloves and safety goggles) should be employed when handling BIO-SOFT LFS07. Avoid contact with eyes and nose, or prolonged contact with the skin. Wash thoroughly after handling. BIO-SOFT LFS-07 dilutes easily into water with minimal tendency to form gels at room temperature and above.

Packaging Storage Recommendations

BIO-SOFT LFS-07 should be stored in closed containers and kept in a cool, dry place away from incompatible materials (see Section 10 of the SDS). Product should be stored at temperatures from 0 ºC (32 ºF) to 50 ºC (122 ºF). If material is frozen it should be heated gently and stirred to ensure it is homogeneous prior to use.