Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Agrochemical Functions

- Cleaning Ingredients Functions

- Industrial Additives Functions

- CAS No.

- 68154-97-2

- EC No.

- 614-340-8

- Product Families

- Surfactant Type

Nonionic.

Features & Benefits

- Labeling Claims

- Agrochemicals Features

- HII Features

- Industrial Additives Features

- Features

Preservative Free

- Biodegradability

MAKON NF-12 is biodegradable.

- Nonionic Alkoxylates

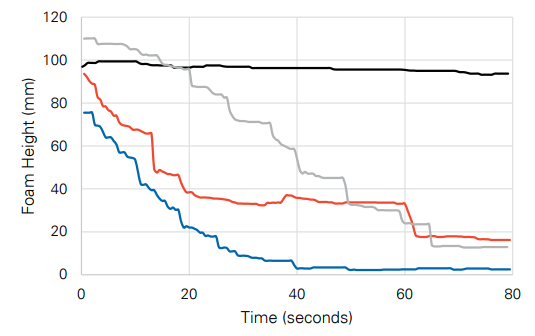

Low foam nonionic alkoxylates (containing both EO and PO) are useful in applications where fast foam break is desired. They can be low foaming below their cloud point, however, foam will break faster when they are used above their cloud point. Figure 2 shows the Stepan products that exhibit low, unstable foam that quickly dissipates compared to a low foam nonionic ethoxylate (control) that creates low, stable foam.

Trade Name Cloud Point (°C) MAKON® NF-12 15 Figure 2: Fast Foam Break

Method: Air sparging method with Dynamic Foam Analyzer (0.3 L/min air injection for 25 seconds), 0.1 wt% surfactant solution in deionized water at 25°C.

Applications & Uses

- Applications

- Applicable Processes

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Applications

MAKON NF-12 is a nonionic surfactant that exhibits low foaming properties and excellent wetting action. MAKON NF-12 may be formulated into highly alkaline built liquid systems with the aid of a hydrotrope such as STEPANATE® SXS or BIO-TERGE® PAS-8S (or BIO-TERGE PAS 7S). Solutions of MAKON NF-12 resist foam development even under extreme or prolonged agitation; they are completely non-foaming above 25 °C. MAKON NF-12 can be used in a variety of applications including mechanical dishwashing, rinse aids, metal cleaning, spray washing, general purpose cleaning, emulsion polymerization, textile wetting and scouring, oil field additives, agricultural adjuvant and non-foaming emulsions.

- Product Applications

- Clean-In-Place (CIP).

- Ware Washing.

- Automatic Dishwash Detergents.

- Metal Cleaning.

- Machine Floor Scrubbing.

- Cleaning in Food and Beverage Production.

- Parts Washing.

- Industrial and Commercial Laundry.

Properties

- Formulation Type

- Physical Form

- Appearance

- Pale, straw colored liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Cloud Point (1% in water) | 15 | °C | — |

| pH (1% in 50:50 IPA:Water) | 6 | — | — |

| Actives Content | 100 | % | — |

| Color | max. 2 | — | Gardener Scale |

| Density | 1 | g/ml | — |

| Freeze Point | -12 | °C | — |

| Viscosity (at 25°C) | 230 | cPs | — |

| Viscosity (at 60 °C) | 45 | cPs | — |

| Pour Point | -10 | °C | — |

| Flash Point | min. 94 | °C | PMCC Flash Point Tester |

| HLB | 6 | — | — |

| Regulated Volatile Organic Chemicals | 0 | % | U.S. EPA |

| Ross-MilesFoam Height (Initial) | 0.4 | cm | — |

| Ross-MilesFoam Height (5 min) | 0.2 | cm | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

- The international inventories (country clearances) of MAKON NF-12 can be found in Section 15 of the Safety Data Sheet (SDS). It is the responsibility of the formulator to review the chemical control regulations for each country where the end product is intended to be sold or used.

- MAKON NF-12 is available as Kosher certified.

Safety & Health

- Health Effects

MAKON NF-12 is slightly toxic orally (Oral LD50=1.8 g/kg).

Packaging & Availability

- Standard Packaging

MAKON NF-12 is available in drums and in bulk quantities.

Storage & Handling

- Storage & Handling

Normal safety precautions (i.e., gloves and safety goggles) should be employed when handling MAKON NF-12. Contact with the eyes and prolonged contact with the skin should be avoided. Wash thoroughly after handling material. It is recommended that MAKON NF-12 be stored in sealed containers and kept in a cool, dry place.

Bulk Storage Information

MAKON NF-12 can be stored in vessels of 316 stainless steel, but carbon steel is adequate. Material should be stored between 80-110 °F (27-43 °C). An internal hairpin coil of stainless/ carbon steel with low pressure steam (under 50 psig) should be used if heating is required. Mild agitation is required if the tank is heated. Material is heat sensitive and agitation prevents localized heating. Heating may not be required for inside storage if the tank is turned over frequently. Stainless steel 316 is preferred for pumps, pipes and transfer lines; however, carbon steel is adequate.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace practices should be used to control these exposures.