Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- INCI Name

- Agrochemical Functions

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Industrial Additives Functions

- CAS No.

- 1300-72-7

- EC No.

- 215-090-9

- Technologies

- Product Families

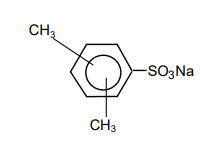

- Chemical Structure

Features & Benefits

- Benefit Claims

- Labeling Claims

- HII Features

- Biodegradability

- STEPANATE® SXS-E is biodegradable (> 90% according EEC 82/243)).

Applications & Uses

- Applications

- Application Format

- Bath & Shower Applications

- Hair Care Applications

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Personal Hygiene Applications

- Skin Care Applications

- Applications

STEPANATE® SXS-E is used in liquid detergent formulations as a solubiliser, coupling agent and cloud point depressant. The hydrotropic or solubilising properties of STEPANATE® SXS-E allows materials to be incorporated into formulations that normally are not compatible. STEPANATE® SXS-E is also useful in lowering the cloud point or crystallization temperature of complex blends. STEPANATE® SXS-E contains no alcohol so it will not decrease the flash point of your formulation. It is also chemically inert in most formulations. STEPANATE® SXS-E is commonly used as a coupling agent for surfactants in phosphate and silicate solutions. The coupling ability of STEPANATE® SXS-E makes it possible to formulate detergents containing high percentages of inorganic builders. Heavy duty cleaners, wax strippers and complex dishwashing detergents can also be prepared without the use of organic solvents. It is also used as a non-caking agent in spray dried detergents.

Properties

- Physical Form

- Appearance

- Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Actives Content | 40 | % | — |

| Color | max. 100 | — | Apha Scale |

| Melting Point | max. 15 | °C | — |

| pH (in 8% active aqueous solution) | 9 | — | — |

| Sodium Sulphate Content | max. 2.0 | % | — |

| Density (at 20°C) | 1.17 | g/cm | — |

Regulatory & Compliance

- Certifications & Compliance

- Clearances

All active components of STEPANATE® SXS-E are listed in the following countries; the registration numbers for the active ingredient are included in parentheses: Europe (EINECS 215-090-9), Canada (DSL 1300-72-7), Australia (AICS 1300-72-7), Korea (ECL KE-11217), United States (TSCA 1300- 72-7), Philippines (PICCS 1300-72-7), Japan (ENCS 3-1909), China (EICS Part.3), New Zealand (HSR 003382) and Mexico (INSQ listed). It is the responsibility of the end user to review the chemical control regulations for each country.

Packaging & Availability

- Standard Packaging

STEPANATE® SXS-E is available in drums (200Kg), intermediate bulk containers (1000kg) and in bulk quantities.

Storage & Handling

- Storage & Handling

Normal safety precautions (i.e. gloves and safety goggles) should be employed when handling STEPANATE® SXS-E. Contact with eyes and prolonged contact with the skin should be avoided. Wash hands thoroughly after handling material. It is recommended that STEPANATE® SXS-E be stored in sealed containers and kept in a cool, dry place. Liquipack or HPDE plastic drums are recommended for storage of STEPANATE® SXS-E. If the material is exposed to low temperatures (below 15°C), it can crystallize and separate. It shou ld be heated gently and stirred in order to reconstitute the clear liquid and to ensure it is homogeneous before use. After reheating and homogenization, it is possible that the pH drifts slightly. This is normal and does not affect the product performance.

Bulk Storage Information

STEPANATE® SXS-E should be stored in 316 stainless steel or fiberglass with a corrosion liner. Mild agitation is recommended while storing to maintain homogeneity. An internal hairpin coil of 316 stainless steel with low pressure steam (under 50 psig) should be used if heating is required. Pumps, pipes and transfer lines should be 316 stainless steel.