Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Agrochemical Functions

- Cleaning Ingredients Functions

- Industrial Additives Functions

- CAS No.

- 68608-88-8

- EC No.

- 271-807-5

- Technologies

- Product Families

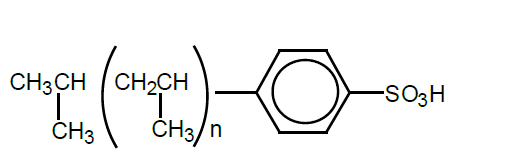

- Chemical Structure

n=3

n=3

Features & Benefits

- Biodegradability

Product is biodegradable.

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Application Area

- Home Care Applications

- I&I Cleaning Applications

- Applications

SULFONIC 100 is an economical and versatile, biodegradable surfactant intermediate. This product can be neutralized with a variety of inorganic bases and organic amines to give a wide range of sulfonates with the properties of your choice. SULFONIC 100 contains a minimum of sulfuric acid and upon neutralization produces material with little salt, light color and low odor. Both water soluble and oil soluble salts can be formed depending upon the choice of base. SULFONIC 100 is useful as a drilling foamer; it can also function as a catalyst in acid-catalyzed reactions. The salts can be in styrene butadiene rubber (SBR) latex. Amine salts can be used as acid catalysts in aqueous systems.

Properties

- Formulation Type

- Physical Form

- Appearance

- Clear to slightly hazy, dark brown liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Actives Content (EW 326) | min. 95 | % | — |

| Density (at 38°C) | 1.03 | g/ml | — |

| Flash Point | min. 94 | °C | PMCC Flash Point Tester |

| Freeze Point | 9 | °C | — |

| pH | max. 1 | — | — |

| Pour Point | 12 | °C | — |

| Regulated Volatile Organic Chemicals | 0 | % | U.S. EPA |

| Viscosity (at 25°C) | 11000 | cPs | — |

Regulatory & Compliance

- Chemical Inventories

- Clearances

- The international inventories (country clearances) of SULFONIC 100 can be found in Section 15 of the Safety Data Sheet (SDS). It is the responsibility of the formulator to review the chemical control regulations for each country where the end product is intended to be sold or used.

- SULFONIC 100 is available in Kosher grade.

- SULFONIC 100 is approved for use as inert ingredients under U.S. EPA 40CFR 180.910 and 180.930.

Technical Details & Test Data

- Neutralization of SULFONIC 100

Neutralization Information: Temperature and pH must be controlled during neutralization of SULFONIC 100 to prevent darkening of the product and corrosion of stainless-steel equipment. The reaction temperature should not be allowed to exceed 50 °C and the pH should not go below 6.5. Approximate amounts of SULFONIC 100 and various alkalis for neutralization to make 100 lbs of active dodecylbenzene sulfonate are shown below. Actual requirements will vary with each shipment. It may be necessary to make final adjustments based on pH, adding more acid to lower the pH or more alkali to raise the pH, until the product is approximately neutral.

Neutralization of SULFONIC 100 to obtain 100 lbs of Alkylbenzene sulfonate

Alkali SULFONIC 100 25.2 lbs. NaOH (50%) 97.7 lbs. SULFONIC 100 93.3 lbs. 33.1 lbs. Triethanolamine (85%) 72.8 lbs. 40.0 lbs. Ammonium Hydroxide (28% NH3) 99.1 lbs.

Packaging & Availability

- Standard Packaging

SULFONIC 100 is available in drums and in bulk quantities.

Storage & Handling

- Storage & Handling

- SULFONIC 100 is a strong acid and should be handled with extreme care. Avoid contact with eyes and skin. Wash thoroughly after handling material.

- It is recommended that SULFONIC 100 be stored in closed containers and kept in a cool, dry place.

- Bulk Storage Information: SULFONIC 100 should be stored in vessels of 316 stainless steel or fiberglass with a corrosion liner. Heating and agitation are recommended for outside storage. Material should be stored between 80 - 100°F (27 - 38°C). An internal hairpin coil of 316 stainless steel with low pressure steam (under 50 psig) should be used if heating is required. Pumps, pipes and transfer lines should be 316 stainless steel.

- For the purposes of offloading and packaging, the product may be heated to a maximum of 140°F (60°C). The product should not be kept at this temperature for longer than 1 week.