Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Type

121°C (250°F) Cure, Epoxy Prepreg System

Features & Benefits

- Product Highlights

- Excellent system for out of autoclave cure

- Toughened for good impact resistance

- MIL-R-9300 qualified

- Ideal for low-to-medium service temperature Applicationss

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Recommended Applications

- Energy

- Aerostructures

- Radome

- Industrial

- Secondary aircraft structures

- Radomes with glass, quartz, and Kevlar®

- Reflectors

- Sporting goods

- Knee braces and other related medical items

- General purpose composites

Properties

- Physical Form

- Mechanical Properties

- Thermal Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Modulus | 2.8 (0.4) | Gpa (Msi) | — |

| Compressive Strength | 115 (16.7) | MPa (Ksi) | — |

| Flexural Modulus | 3.4 (0.50) | Gpa (Msi) | — |

| Flexural Strain | 5.5 | % | — |

| Flexural Strength | 156 (22.6) | MPa (Ksi) | — |

| Tensile Modulus | 3 (0.44) | Gpa (Msi) | — |

| Tensile Strain | 2.5 | % | — |

| Tensile Strength | 75 (10.9) | MPa (Ksi) | — |

| Value | Units | Test Method / Conditions | |

| Coefficient of Thermal Expansion (CTE) | 71 (39) | ppm/°C (ppm/°F) | — |

| Glass Transition Temperature (Tg) | 125 (257) | °C (°F) | — |

| Value | Units | Test Method / Conditions | |

| Density | 1.17 | g/cc | — |

| Dielectric Constant at 10 GHz | 3 | — | — |

| Dielectric Constant at 10 GHz on 4581 quartz | 3.26 | — | — |

| Loss Tangent at 10 GHz | 0.019 | — | — |

| Loss Tangent at 10 GHz on 4581 quartz | 0.0081 | — | — |

| Moisture Absorption after 24 hr water boil | 2 | % | — |

Technical Details & Test Data

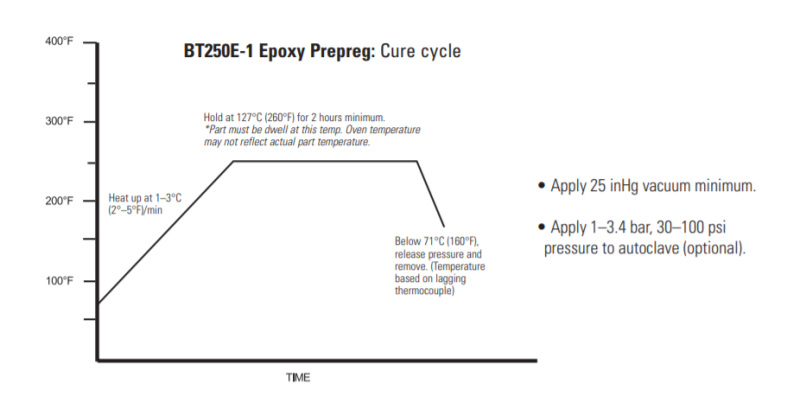

- Recommended Cure Cycle

Storage & Handling

- Shelf Life

- Tack Life: Up to 30 days at ambient

- Out Life: Up to 30 days at ambient

- Frozen Storage Life: 12 months at -18°C (< 0°F)

Tack life is the time during which the prepreg retains enough tack, drape, and handling for component lay-up. Out life is the maximum time allowed at ambient temperature before cure. *Ambient is 18–22°C (65–72°F)

- Product Handling

The following guidelines are provided to our customers to assure that best practices are used to attain the best results from Toray Advanced Composites epoxy products. Keep in mind that these procedures represent best practices for all composite prepreg and adhesive materials.

-

FREEZER STORAGE: Epoxy resin materials have good shelf life at room temperature; however, the life and performance of the material is best preserved with the following basic guidelines. Refer to the shelf life included in the product certifications. The epoxy material should be sealed in an airtight bag and kept frozen below -18°C (0°F) when not being used for longest life and most consistent performance. A good safety measure is to have a bag of desiccant (silica moisture absorber) in the core of the prepreg roll to assure the best protection from moisture ingression.

-

MOISTURE ABSORPTION AND SENSITIVITY: While very resistant to moisture absorption after cure, epoxies can be adversely affected by moisture uptake prior to cure. For this reason, all materials must be completely thawed to room temperature prior to opening the sealed bag to avoid condensation on the material. Also, it is good practice to keep prepreg and; in-process hardware in a sealed bag or vacuum bag if it will be exposed to the atmosphere for long periods of time.

-

HANDLING OF MATERIALS: When handling any prepreg materials, one should always wear clean, powder-free latex gloves. This will assure that no hand oils are transferred to the prepreg and/or composite during processing. The presence of oils in the part could lead to problems in both mechanical and electrical performance of the part. This also guards against dermatitis that may occur with some users.

- NONMETALLIC HONEYCOMB AND FOAM CORE US: When using nonmetallic honeycomb and foam core materials for sandwich structures, the materials should always be dried in an oven prior to lay-up to drive off any moisture that may be in the core. The core should be cooled in the presence of a desiccant to avoid moisture uptake. Following drying, it is always best to use the material as soon as possible. Recommended core dry time/temp: 121°C (250°F) for 3–4 hours.

-