Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Product Highlights

- High radiation resistance

- Low microcracking even under severe thermocycling

- Low moisture absorption

- Low dielectric constant and dissipation factors

- Low stress-free cure temperature with high level of cure

- Outstanding mechanical properties

- Compatible adhesive is EX-1516

Applications & Uses

- Markets

- Composites Processing Methods

- Recommended Applications

- Space & Satellite

- Radome

- Optical benches

- Reflectors

- Radomes and antennas

- Low observable structures

- Adhesive Properties And Uses

Toray Advanced Composites cyanate ester resins have been formulated to have good self-adhesive properties to core materials. However, this should not be taken as a green light to eliminate a film adhesive from a cored, structural piece of hardware. This option has been given by Toray for customers who are looking for the best electrical properties available by not using a film adhesive. Toray recommends that the structural integrity be verified per customer specification prior to end item usage and takes no responsibility otherwise. If this option is exercised, the following modified cure cycle has been found to work well.

- Ramp the part to 66–71°C (150–160°F) (Keep Pressure < 15 Psi)

- Dwell for approximately 1 hour

- Ramp the part to the recommended cure temperature for the resin and cure per the provided standard cure cycle.

Properties

- Physical Form

- Thermal Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Coefficient of Thermal Expansion (CTE) | 61 (34) | ppm/°C (ppm/°F) | — |

| Tg (by DMA) cured at 121°C (250°F) | 121 (249) | °C (°F) | — |

| Tg (by DMA) post cured at 177°C (350°F) | 174 (345) | °C (°F) | — |

| Thermal Conductivity | 0.169 | W/m.K | — |

| Value | Units | Test Method / Conditions | |

| Density | 1.156 | g/cc | — |

| Dielectric Constant at 10 GHz | 2.8 | — | — |

| Loss Tangent at 10 GHz | 0.004 | — | — |

| Moisture Absorption P75 laminate saturation at 27°C | 0.04 | % | — |

| Outgassing (CVCM) | 0.01 | % | — |

| Outgassing (TML) | 0.18 | % | — |

Technical Details & Test Data

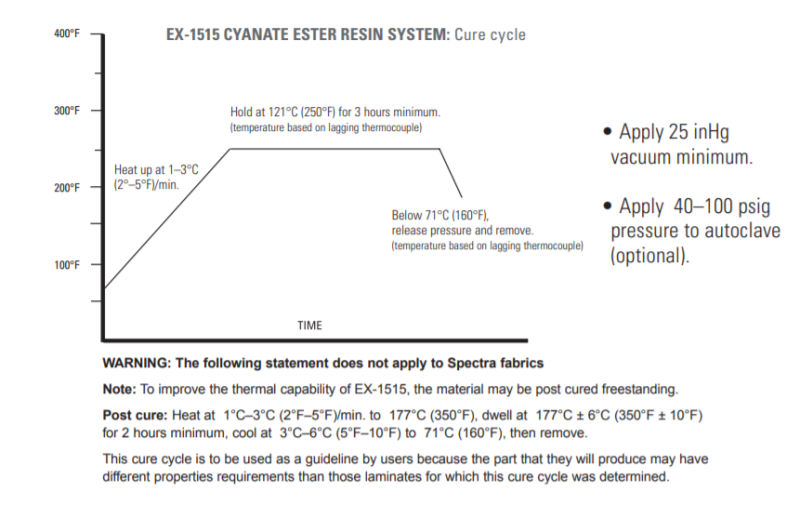

- Recommended Cure Cycle

- Curing Method

Toray recommends that CE composite parts bagged for cure should be performed as follows.

- Release the tool surface

- Lay-up part using standard debulking procedures

- Dam the edges of the part for cure.

- Place 1 ply of porous Teflon® or perforated Teflon® onto the bag surface of the part.

- Place bleeder layers over porous Teflon® material and trim to the part periphery

- Place a non-porous layer of Teflon® over the part.

- Utilize a breather cloth to facilitate vacuum draw.

- Install vacuum bag on the tool for cure

- Follow the provided Toray cure cycle for the particular resin system.

Safety & Health

- Environmental Controls

Toray recommends that any composite or adhesive lay-up be performed in a clean area visibly free from dust. Any work surfaces should likewise be free of residue, dust, or debris. No eating or smoking shall be allowed in the shop area. For radome materials, conductive materials shall not be allowed in the process area. The processing shop area should be maintained between 16–25°C (60–77°F) with a relative humidity of no greater than 70%.

Storage & Handling

- Shelf Life

- Out Life: 21 days at ≤ 21°C (70°F) and ≤ 60% RH

- Frozen Storage Life: 12 months at -18°C (< 0°F) or below

Out life is the maximum time allowed at ≤ 21°C (70°F) and ≤ 60% RH before cure.** ** Out life tested via prepreg tack and drape, and ILSS on 24 ply 7781 fabric laminate cured at 121°C (250°F) under 85 psig pressure for 3 hours.

- Product Handling

The following guidelines are provided to our customers for one specific purpose: to assure that all customers are aware of the manner by which to attain the best possible results from Toray Advanced Composites cyanate ester products. These resin systems will provide sound composite hardware and structures if some simple procedures are followed. Keep in mind that these procedures are good practice for all composite prepreg and adhesive materials and should be used whenever possible.

-

FREEZER STORAGE: E Cyanate Esters (CEs) should always be sealed in an airtight bag and kept frozen below -12°C (10°F) when not being used. A good safety measure is to have a bag of desiccant (silica moisture absorber) in the core of the prepreg roll just in case a pinhole in the bag or other problem occu

-

MOISTURE ABSORPTION AND SENSITIVITY: While very resistant to moisture absorption after cure, CEs can be adversely affected by moisture uptake prior to cure. For this reason, all materials must be “thoroughly thawed” to room temperature prior to opening the sealed bag to avoid condensation on the material. Also, it is good practice to keep prepreg and in-process hardware in a sealed bag or vacuum bag if to be exposed to the atmosphere for long periods of time.

-

HANDLING OF MATERIALS: When handling any prepreg materials, one should always be wearing clean, powder-free latex gloves. This will assure that no hand oils are transferred to the prepreg and/or composite during processing. The presence of oils in the part could lead to problems in both mechanical and electrical performance of the part. This also guards against any dermatitis that could occur with certain users.

-

NONMETALLIC HONEYCOMB AND FOAM CORE USE: When using nonmetallic honeycomb and foam core materials for sandwich structures, the materials should always be dried in an oven prior to lay-up to drive off any moisture that may be in the core. The material should then be cooled in the presence of a desiccant, to avoid any moisture uptake. Following this procedure, it is always a good idea to use the material as soon as possible to avoid rehydration. Recommended Core Dry Time/Temp: 121°C (250°F) for 3–4 hours (minimum), core must be kept dry until it is used.

-