Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

- Product Type

- 125°C (257°F) Cure

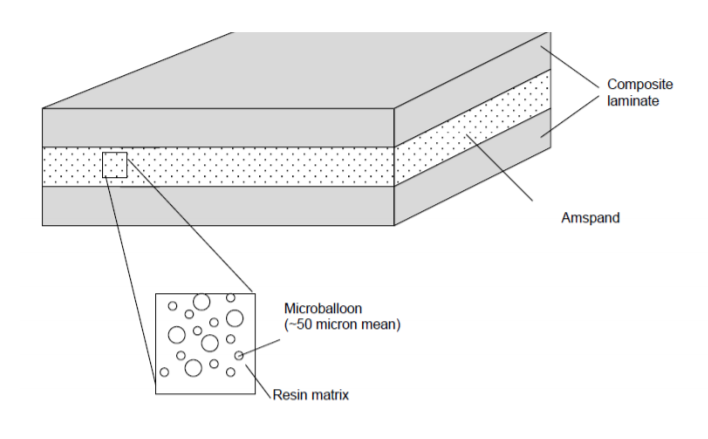

- Expanding Syntactic Core

Features & Benefits

- Materials Features

- Product Highlights

- Density/strength may be tailored by simply changing cure pressure or limiting volume available for expansion.

- Capable of expanding up to 650%**

- Forms a closed cell structure

- Capable of generating internal pressure during cure

- Compatible for co-cure with Toray’s E720 and E722 prepreg

- 30 days out life at ambient temperature ** Variations in heat-up rate, cure temperature, pressure and thickness are all factors that influence the expansion (e.g., at 1-mm thickness an expansion of 250% can be achieved. Increasing the thickness will increase the expansion).

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Recommended Applications

- Sport & Recreation

- Motorsport & Formula 1

- Automotive

- Industrial

- Honeycomb edge filling and splicing

- Honeycomb core stabilization

- Use as a filling core in closed mold operations

Remove from cold storage and allow to reach room temperature before removing from polythene bag. Trim to required shape and remove release paper from one side. Place in position and remove remaining release paper.

Caution: ES72A-2 syntactic core contains a reactive resin system and care must be taken to avoid exothermic heating during the cure.

Properties

- Appearance

- Charcoal Gray

- Cured Properties

- Uncured Properties

| Value | Units | Test Method / Conditions | |

| Density | 0.10 to 0.40 | g/cm3 | — |

| Tg (by DSC) | 114 (237) | °C (°F) | — |

| Value | Units | Test Method / Conditions | |

| Density | 0.9 | g/cm3 | — |

| Flexibility | Pliable at room temperature | — | — |

| Surface weight nom. for 1 mm thickness | 900 | g/m2 | — |

| Surface weight nom. for 1.5 mm thickness | 1350 | g/m2 | — |

| Surface weight nom. For 2 mm thickness | 1800 | g/m2 | — |

| Tack | Medium | — | — |

| Thickness mm ± 10% as standard | 1, 1.5, and 2 | mm (mm) | — |

Technical Details & Test Data

- Recommended Cure Cycle

- Increase air temperature at 2.5°C (4.5°F)/min to 125°C (257°F) and hold for 1 hour

- Allow to cool to 60°C (140°F) prior to releasing vacuum and removal from mold

Safety & Health

- Product Safety And Shelf Life

Handling Safety:

This product may cause skin irritation. Avoid skin contact. If contact occurs, wash with soap and water at the first opportunity.

SHELF LIFE:

- Out Life : 30 days at 20°C (68°F)

- Storage Life : 12 months at -18°C (0°F) when stored in polythene bags

Out life is the maximum time allowed at room temperature before cure.