Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Cure Method

- Plastics & Elastomers End Uses

Properties

- Physical Properties

Tensile Strength Excellent Rebound Resilience Good Abrasion Resistance Good Tear Resistance Good Mechanical Properties (High Hardness) Good Mechanical Properties (Low Hardness) Fair Compression Set at 70°C Excellent Compression Set at 100°C Excellent Heat Resistance Excellent Low-Temperature Performance Excellent Gas Impermeability Good Transparency (Cured Articles) Fair Hydrolysis (Water) Resistance² Fair Oil Resistance Excellent Diesel/Biodiesel Resistance Excellent Gasoline Resistance Excellent Gasohol (Gasoline/Ethanol 90/10) Good FDA Use (177.2600 Compliant) Insufficient Data Processing Compression Molding Excellent Transfer Molding Excellent Injection Molding Excellent Extrusion³ Excellent Steam Vulcanization⁴ Fair Hot Air Vulcanization⁵ Fair - Low Temperature Properties

- Millathane® Millable urethanes have good low temperature properties.

- Compounds based upon polyether grades having brittle points down to as low as -68°C (-90°F), and compounds based upon polyester grades down to as low as -60°C (-76°C).

- Low temperature flexibility is important for applications such as airplane deicing bladders, automotive parts, and hose for cold temperature use.

- Some grades of both polyether and polyester millable urethanes can stiffen considerably at low temperatures due to crystallization of the polymer.

- Grades that are the most resistant to low temperature hardening are the polyether grades Millathane CM and E40 and the polyester grades Millathane HT and 66.

- Note

¹ Relative properties (to other Millathane polymers/compounds)

² The hydrolysis resistance of polyester urethanes can be significantly improved by the addition of carbodiimide hydrolysis stabilizers. Premilled grades contain 1.5 phr of MillstabTM P, a polymeric carbodiimide hydrolysis stabilizer.³ For extrusion roll building or preforms only.

⁴ Compound must be completely protected from direct steam contact

⁵ Peroxide cured compounds can be cured in hot air (with pressure) if protected from air/oxygen contact

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

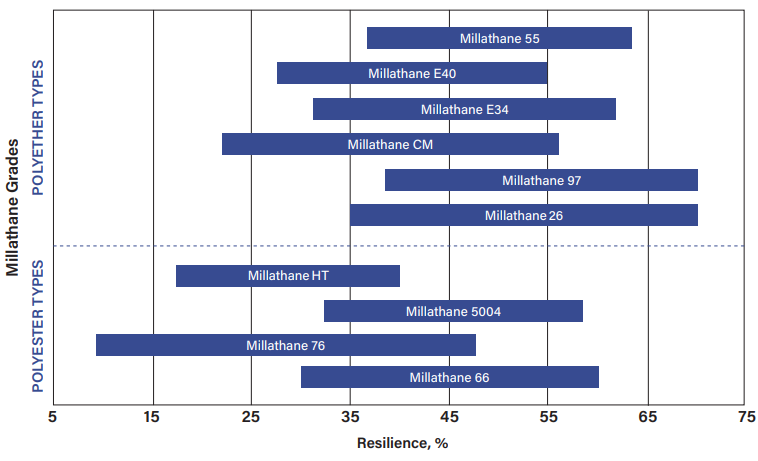

- Resilience/Damping

Millathane millable urethanes can have resilience (rebound) values varying from below 10%, as seen with some Millathane 76 compounds, to over 60%, as seen with several polyether grades.

Low resilience compounds generally have excellent vibration damping characteristics and are used in instrument packaging and other vibration damping applications.

High resilience compounds tend to have lower heat build-up in dynamic applications such as rubber-covered rollers.

Generally, resilience will be higher with low filler loadings than with higher filler loadings. Peroxide cures will tend to give higher resilience than sulfur cures.

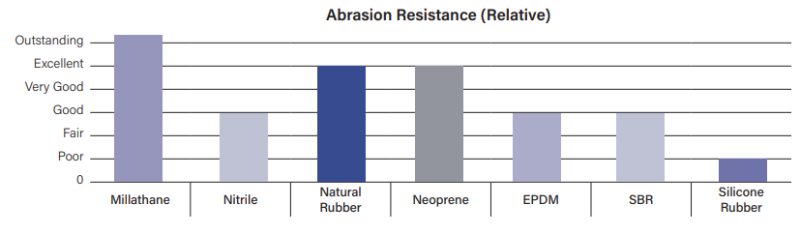

- Abrasion Resistance

- Abrasion resistance is the ability of a surface to resist wearing due to contact with another surface moving with respect to it.

- High resistance to abrasion is important in applications like rollers, belting, and helicopter dust covers.

- The DIN Abrasion Test (ASTM D5963) is one of the most common tests for measuring abrasion resistance.

- It's where a rotating cylindrical sample is passed across a rotating drum of abrasive and the amount of sample volume lost is measured.

- Typical abrasion resistance values for Millathane millable urethane compounds is 50-80 mm³.

- Some compounds can have abrasion resistance values as low as 25 mm³, depending on the polymer, cure system, and formulation.

- Polyurethane rubber provides the highest abrasion resistance of any rubber, synthetic or natural.

- Laboratory tests do not always predict the advantage of Millathane compounds over other rubbers, but field experience often shows a tremendous improvement in product lifetime when millable urethane replaces conventional rubber.

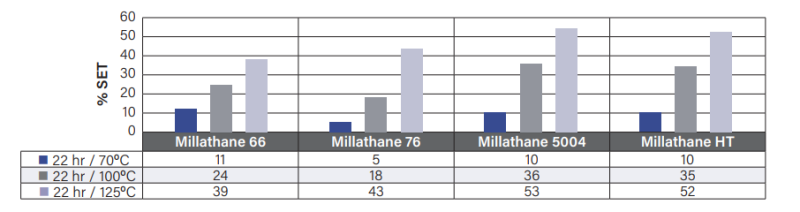

- Compression Set

- Peroxide-cured Millathanes have very good compression-set characteristics at temperatures up to 125°C, with the set increasing as the temperature increases (as is typical for all rubbers).

- The chart below compares the compression set of four polyester Millathane grades at 70°C, 100°C, and 125°C.

- Even lower compression sets can be achieved with compounds, with Millathane 66 giving the best (lowest) set at elevated temperatures.

- Generally, polyester urethanes will have improved compression set compared to polyether grades.

- Peroxide-cured billable urethane compounds will have much better (lower) compression set compared with sulfur-cured compounds, especially when coagents are included along with the peroxides.

- Oil, Fuel and Solvent Resistance

- Polyester grades will have significantly better resistance to oil and solvents than polyether grades.

- Polyester grades should be chosen for applications requiring optimum resistance to these materials, such as printing rollers and seals.

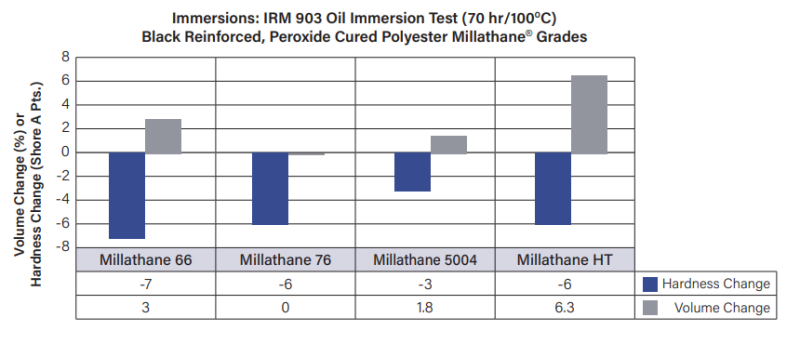

- The chart below compares four polyester Millathane grades for their resistance to IRM 903 Oil.

- All of the compounds showed minor hardness and volume changes after the elevated temperature oil exposure.

- Millathane 5004 and 76 had the lowest volume changes, and Millathane 5004 had the least change in hardness.

- Heat Resistance

- Millable polyurethane rubber is not known for its high-heat resistance, typically being used at temperatures less than100°C.

- Polyester grades of Millathane® have significantly better heat resistance than polyether grades, and peroxide cures will have better heat resistance than sulfur cures.

- For applications that need non-continuous exposure to temperatures up to 150°C, peroxide-cured polyester millable urethanes such as Millathane 66 and 5004 can have very good utility because of their excellent retention of properties.

- The table below shows the excellent heat resistance of a black reinforced, peroxide-cured Millathane 66 compound.

- The physical properties tested showed no hardness change and minor changes in tensile strength and elongation for heat agings conducted from 70°C to 150°C.

- The compression set showed excellent results up to 140°C, the high value of the set at 150°C would make it unsuitable for applications at this temperature.

- Millathane 66 Premilled contains 1.5 parts of the hydrolysis stabilizer MillstabTM P, which is a polymeric carbodiimide.This is beneficial primarily to hydrolysis resistance but also benefits heat aging and compression set resistance.

Heat Aging Conditions Original 70hr/70°C 70hr/100°C 70hr/125°C 70hr/140°C 70hr/150°C Hardness, Shore A 88 88 88 88 88 88 Points Change - 0 0 0 0 0 Tensile Strength, psi (MPa) 3550 (24.5) 3920 (27.0) 4120 (28.4) 2370 (16.3) 2750 (19.0) 3190 (22.0) % Change - 10 16 -33 -23 -10 Elongation, % 155 165 170 90 100 150 % Change - 6 10 -42 -35 -3 Compression Set Conditions 22hr/70°C 22hr/100°C 22hr/125°C 22hr/140°C 22hr/150°C Compression Set, % 4 5 22 35 74 - Gas Permeability

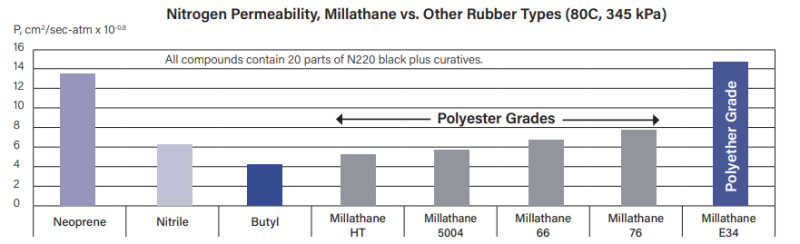

- Millathane millable urethanes have very good resistance to gas permeability, with polyester grades approaching that of butyl rubber.

- A comparison of the nitrogen permeability of several Millathane grades vs. neoprene (CR), nitrile (NBR), and butyl (IIR) rubber is shown in the chart below.

- Polyester millable urethanes have very low gas permeability, comparable to or slightly better than nitrile rubber and slightly defensive to butyl rubber.

- Millathane E34, a polyether polyurethane, had higher (poorer) nitrogen permeability, similar to that of neoprene rubber.