Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Plastics & Elastomers Functions

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Benefits

- High solvating plasticizer with superior plasticizing efficiency

- Compatibility in multiple polymer offering versatility in formulating

- Fast-fusing plasticizer in PVC systems to boost throughput

- Exhibits excellent permanence properties and low volatility

- Features

Phthalate, Fast Fuser With Low Volatility

- Principle plasticizer functionalities for Coatings Adhesives and Sealants

First of all a plasticizer is added to introduce the desired flexibility at low loadings.

Secondly the plasticizer will ensure that the right rheology is achieved in the non cured state. Often thixotropy is required as this will ensure good flowability at high shear rates during extrusion and non sagging properties or high viscosity just after the application of the coating.

Perfect compatibility is the next “must have” property for your plasticizer of choice. This is to avoid adhesive failure due to a migrating plasticizer. The compatibility of your system can be predicted by using the widely spread theory of solubility parameters.

The solubility parameter:

F: is the sum of the “molar” attractions constants, commonly called today “‘Small’s Constants”

V : is the molar volume or the molecular weight divided by the density.

The lower the difference in between the solubility parameter of the polymer and the one of the plasticizer.the higher the compatibility. Graph 1 shows that Santicizer® 261A has an excellent compatibility with a large choice of polymers used in the field of coatings, sealants and adhesives, which is making this plasticizer very versatile for use in the majority of sealant applications.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Ink & Toner Type

- Plastics & Elastomers End Uses

- Uses

Santicizer® 261A has higher molecular weight than Santicizer® 160, but still maintains its high solvating character. This means it continues to be a fast fusing, high efficiency plasticizer, but with lower volatility. Santicizer® 261A is a good option for formulators in applications where permanence during processing and resistance to extraction are key performance parameters.

- Santicizer® in Lubricants Benzyl Esters as seal swell and Phosphate Esters as anti-wear additives

Santicizer® Benzyl Esters as seal swell additives

In crankcase oils, transmission oils and hydraulic fluids the lubricant is in contact with the seal. Those seals can be made of different elastomers. The generally used elastomers are:

- nitrile butadiene rubber (NBR)

- acrylic

- silicone

- fluorinated

While aging, these elastomers tend to become harder (even brittle), tend to shrink and they tend to lose their elastomeric properties (as elongation). When this aging goes along with higher temperatures, as in automotive crankcase oils, this process is even accelerated.

The loss of those elastomeric properties in an engine can be the cause of leaks and thus loss of oil. But in order not to lose the properties of the elastomers and thus prevent leakage some polar additives have to be introduced. Those have to be as compatible as possible with the different elastomers. Alkyl benzyl esters, Santicizer® 261A, Santicizer® 278, Santicizer® Platinum P-1400 & P-1700, are good compatibilizers at a low dosage of 1 to 4 wt% for different type of elastomers. In the volume change aging test according the norm CEC-L-39-T-96 the addition of a seal swell additive as a benzyl ester is necessary to avoid shrinkage of the seal when put in a pure poly alpha olefin.

Volume Change CEC-L-39-T-96 Acrylic Seal NBR Seal Time/Temperature 1 week 150ºC 1 week 100ºC Pure PAO 6 97.6 99.6 PAO 6 +2% Santicizer Benzyl Ester 100.8 106.4

Properties

- Physical Form

- Appearance

- Clear Liquid

- Typical Properties

- Valtris Santicizer® in Polyurethane Applications

Polyurethane systems offer a wide variety of desirable performance features in coatings, adhesives, caulks, sealants and castable applications. Polyurethanes are used for their flexibility, excellent durability, tear resistance, and resilience. Valtris Santicizer phthalate and non-phthalate plasticizers are well suited for polyurethane applications, both 1K and 2K formulations.

Benefits of using Valtris plasticizers:

- Enhance processability by modifying rheological properties.

- Reduce elastic modulus and shore A hardness.

- Improve flexibility and maintain mechanical properties.

- Polar molecules, therefore, highly compatible with excellent permanence in urethane technology.

- Low Hydroxyl number and low moisture content.

- Low neat color.

- Excellent abrasion resistance

Sample Viscosity (low) Shear Recovery (high) Tack Time(fast) Cure Through(fast) Shore A Permanence Hydroxyl Number (low) Santicizer® 261A + - + + = = ++ - Valtris Santicizer® in MS Polymer Applications.

Modified silane polymers were developed 30 years ago, and we have seen a large increase in both the European and North American markets due to its great advantage of being an elastic adhesive compared to polyurethane and PVC adhesives. Modified silanes are one component adhesives which react and cure under the action of moisture, and once cured acquire elastic properties and strength of an elastomeric material. Valtris Santicizer phthalate and nonphthalate plasticizers are well suited for MS Polymer formulations.

Benefits of using Valtris plasticizers:

- Enhance processability by modifying rheological properties.

- Reduce Shore A Hardness.

- Improve flexibility and maintenance of mechanical properties.

- Equal tack time and cure through

- Better Water Sensitivity

Sample Viscosity (low) Shear Recovery (high) Tack Time Cure Through Shore A Migration Water Sensitivity (low % absorbed) Santicizer® 261A + ++ = - = = = - Valtris Santicizer® in SPUR Applications

SPUR: Silylated Polyurethanes. SPURs have a silane curing mechanism and a polyurethane backbone, but they do not contain the unreacted isocynates like standard polyurethane technology. This makes them more esthetic to the environment and they have become increasingly appealing to adhesives, sealants and coatings. SPUR formulations offer fast room-temperature cure and good durability when compared to a standard polyurethane system. Generally, a plasticizer is used in a SPUR formulation because of the need for specific properties the plasticizer can provide that the formulator is not able to reach on its own. Valtris plasticizers are compatible with SPUR technology and can offer properties not seen with standard SPUR formulations.

Benefits of using Valtris plasticizers:

- Enhance processability by modifying rheological properties.

- Reduce elastic modulus and shore A hardness.

- Improve flexibility and maintain mechanical properties.

- Offer better low temperature flexibility.

- Low Hydroxyl number and low moisture content.

- Low neat color.

Sample Viscosity (low) Shear Recovery (high) Cure Through Shore A Water Sensitivity (lower % absorbed) Permanence Cold Temperature Flexibility (lower temp) Hydroxyl Number (lower) Santicizer® 261A ++ - = = = = ++ ++ - Acrylic Sealant with Santicizer

Sealant Formulation

phr Acrylic emulsion (55% solids) 100 Santicizer® 261A 27.5 Filler 176 Water 6.4 Surfactant 2.2 Biocide 0.3 Ehtylene Glycol 3 Dispersants 0.5 Thickener 0.25 Mineral spirits 4 Silane adhesion promoter 0.2 Colorant 2.5 Sealant Properties

Total Solids 81.1% Density 1.58 kg/dm³ Shore A Hardness 45 Stain test No stain Peelstrength to masonry,glass or aluminum 1750 – 3150 N/m

| Value | Units | Test Method / Conditions | |

| Acidity | max. 0.25 | meq/g | — |

| Color | 75 | — | APHA |

| Moisture Content | max. 0.03 | % | KF |

| Specific Gravity (at 25°C) | 1.055 - 1.064 | — | — |

| Viscosity (at 25°C) | 101 | cP | — |

| Assay Content | min. 98.5 | % | — |

Regulatory & Compliance

Technical Details & Test Data

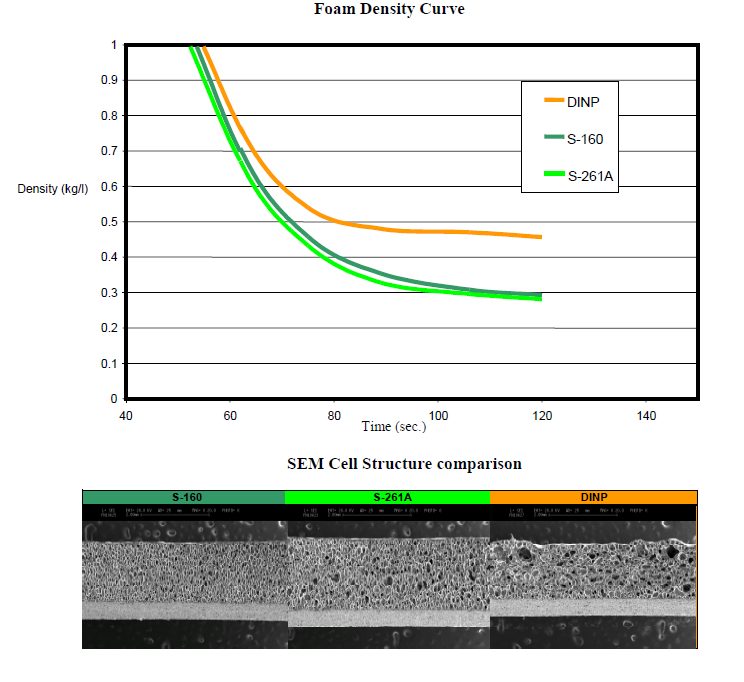

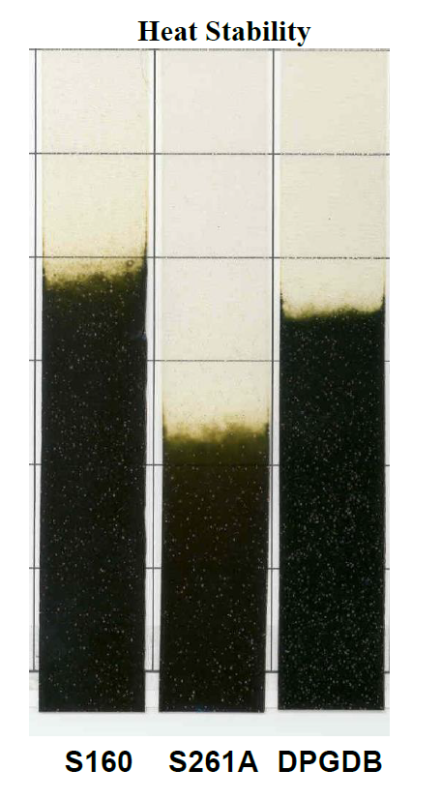

- Foam Characteristics

Santicizer® 261A is fast fusing benzyl phthalates with a high level of permanence, yet they retain the easy processing features of a monomeric plasticizer. Santicizers® are used in many applications including PVC films, fabric coatings, plastisols, foams, sealants and lacquers. Listed below is a comparison of some competitive products commonly in similar foam based applications.

- Santicizer® 261A: Product Comparison

Santicizer® 261A is a fast fusing benzyl phthalate with a high level of permanence, yet retains the easy processing features of a monomeric plasticizer. Santicizer® 261A is used in many applications including PVC films, fabric coatings, plastisols, foams, sealants and lacquers. Listed below is a comparison of some competitive products commonly in similar applications.

S-261A B2088 B50 B988 DINP DINCH Volatility (loss by EPA Method 24) 0.3% 1.7% 2.0% 2.6% 0.1% 0.2% Cold Temp. Flex (Clash and Berg) -23.7 C -16.8 C -14.2 C -9.9 C -33.4 C -43.5 C Hardness (Shore A) 72 75 72 71 76 78 Water Resistance (% change) 0.3 1.0 1.6 0.9 0.3 0.3 Santicizer® 261A has a unique position as a material that holds an optimum balance of the most beneficial properties for PVC applications:

- Low fusion energy requirement required to processing ease, while maintaining a low volatility needed to keep the plasticizer in the material during and after processing.

- Low density to add cost benefit, while keeping a low viscosity at various temperatures to aid in handling and production processes.

- High plasticizer efficiency to reduce required loading, while offering high physical properties like tensile strength and elongation in applications.

- Good plasticizer performance at low temperatures, but retained permanence within the material.

- Micro-biological resistance that helps maintain finished products performance integrity and helps keep products free of ugly mildew and stains.

Packaging & Availability

- Country Availability

- Regional Availability