Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Industrial Additives Functions

- Technologies

Features & Benefits

- Industrial Additives Features

- Operating Benefits if DURAGUARD S100 Absorbent

- William Blythe has combined innovation in chemistry with our expertise in manufacturing technology to produce a high capacity absorbent for H₂S removal and co-removal of H₂S and mercury from hydrocarbon gas and liquid streams, offering unrivaled durability and performance to natural gas processing operators.

- The DURAGUARD S100 absorbent is engineered to have enhanced porosity, resulting inavery high capacity for H₂S.

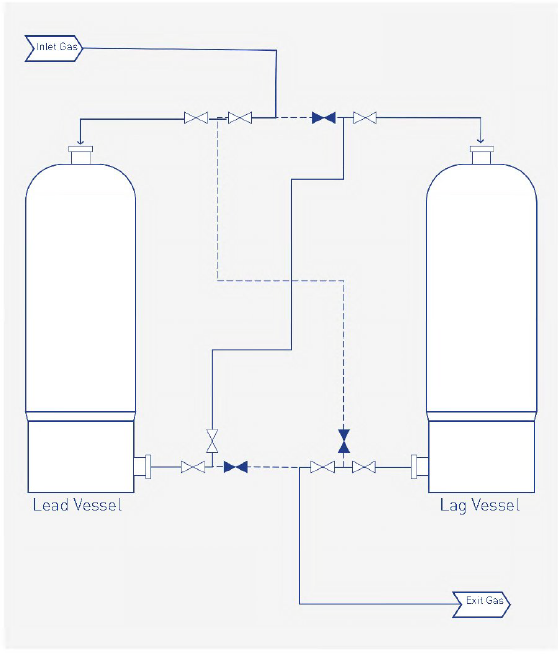

- Operating benefits include impurity removal to very low levels. Product life depends on the amount of H₂S that passes through the bed, allowing for variations in the gas flow and impurity level. The sharp absorption profile means that single bed operation is possible. However, a lead-lag configuration offers the flexibility to change-out spent absorbent while the plant is on-line allowing continuous, uninterrupted operation.

- Benefits

- Sulfur removal to very low levels (<0.1 ppm v)

- Reliable performance and long predictable life

- Low and stable pressure drop

- Spent absorbent can be re-processed

Applications & Uses

- Markets

- Applicable Processes

- Applications

- DURAGUARD S100 is a high porosity metal oxide granule used for H2S removal from hydrocarbon gasses and liquids by reaction with metal oxide in non-regenrable fixed beds.

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Bulk Density | 1300 - 1500 | kg/mᶟ | - |

| Crush Strength | min. 20 | N | - |

| Shape | Spherical | - | - |

| Size | 2.8 - 4.75 | mm | - |

| Sulphur Capacity | min. 370 | kg s/mᶟ | - |

Technical Details & Test Data

- Full Life-cycle

- Reprocessing of spent DURAGUARD absorbent via environmentally friendly and sustainable routes can be managed by William Blythe, ensuring minimum environmental impact from the process.

- We offer customers a turnkey, full solution approach comprising: technical support for the full life-cycle of the absorbent, providing designs for new beds, advice and supervision on loading and un-loading of absorbent, process optimisation during operation and the re-processing of spent absorbent.

Lead-Lag Vessel Operation

Packaging & Availability

- Packaging

1mᶟ big bags in octoboxes or 200 liter steel drums