- Polymer Name:PP/EPDM

- Processing Methods:Injection Molding

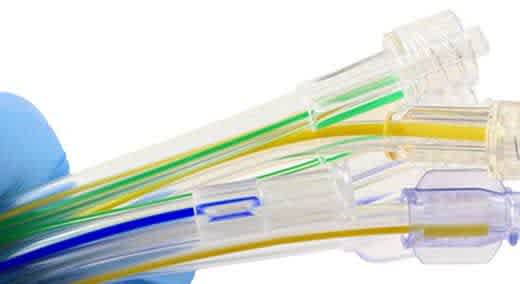

- End Uses:Toys, Household Goods, Containers, Closures, Soft Touch Applications, Food Preparation Equipment, Caps, Protective Caps, Kitchenware, Handles, Food Packaging, Sealing Lip, Seals

- Density:940.0 - 940.0 kg/m³

- Tear Strength:23.0 - 23.0 kN/m

- Features:Chemical Resistant, Soft, Soft Touch, Food Contact Acceptable, Flexible, Excellent Hydrolysis Resistance, Hot Air Resistant, Good Colorability, Good Flow, Ozone Resistant, Hydrolysis Resistant, Good Weather Stability

MOCOM Compounds ALFATER® XL A60I 4FC0010 is a thermoplastic vulcanisate (PP+EPDM) of natural color, bright inherent color, and blue. Its pre-drying conditions include a dry air (dessiccant) dryer at 70-80°C for 2-4 hours, with a maximum moisture content of less than 0.10%. Special features of the polymer include being food contact compliant with EN 71-3, good colorability, good weathering resistance, good chemical resistance, good ozone resistance, good hot air resistance, and good hydrolysis resistance. It is used in the packaging, household goods, food processing industry, toys, and other areas for injection molded parts, such as seals, sealing lips, handles, soft touch elements, protection caps, caps/closures, containers, and kitchenware. It adheres to polypropylene homopolymer, polypropylene copolymer, polyethylene, thermoplastic vulcanisate (PP+EPDM), thermoplastic olefin elastomer, and thermoplastic elastomer general.