Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

Features & Benefits

- Features

- Combines a fine pore structure for enhanced adsorption of trace contaminants with high catalytic activity for theirelimination

- Not impregnated

- Improved trace organic capacity

- High hardness

- Simple equipment design (no pumps or addition of chemicalsrequired)

- Smaller system size as compared to standard carbons; lower capital requirements

- No safety concerns with exotherms or toxicity as with impregnatedcarbons

- Wide applicability; can eliminate chemical addition

- Recycling and Reactivation

Though CENTAUR is 100-percent freshly manufactured virgin GAC, it can be recycled and reused through thermal reactivation to restore its adsorptive capacity. This eliminates the costs and long-term liability associated with the disposal of spent GAC, and provides customers with a consistent, reliable supply of filtration media.

Applications & Uses

- Markets

- Applicable Processes

- Applications

- CENTAUR NDS 12x40 can be utilized in the liquid phase for the promotion of oxidation, reduction, decomposition, substitution, and elimination reactions. Specific applications include chloramines and hydrogen sulfide removal from potable water.

- CENTAUR NDS 12x40 maximizes reaction kinetics with some increase in pressure drop compared to larger mesh products. CENTAUR NDS 12x40 can be utilized in applications such as POU (point of use) and POE (point of entry) water filters and dialysis water treatment.

- Bottle & Brewing

- Hemodialysis

- Drinking Water (Potable)

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH (Extractable) | 5 - 8 | - | - |

| NSF 42- Arsenic | max. 10 | ppb | - |

| NSF 42- Aluminum | max. 200 | ppb | - |

| Prop 65 - Aluminum | max. 200 | ppb | - |

| Moisture Content (as Packaged) | max. 3 | wt% | - |

| Prop 65 - Antimony | max. 3 | ppb | - |

| US Mesh (0.425mm, PAN, max. 40 ) | max. 4 | wt% | - |

| 12 US Mesh (1.70 mm) | max. 5 | wt% | - |

| Prop 65 - Arsenic | max. 5 | ppb | - |

| NSF 42- Antimony | max. 6 | ppb | - |

| Abrasion Number | min. 75 | - | - |

| Iodine Number | min. 900 | mg/g | - |

Regulatory & Compliance

- Regulatory

This product complies with the requirements for activated carbon as defined by the Food Chemicals Codex (FCC) (8th Edition) published by the U.S. Pharmacopeia, is certified as a component to the NSF/ANSI 42 – Drinking Water Treatment Units – Esthetic Effects standard, and meets the requirements for arsenic level for a raw material as defined by the consent judgment dated September 9, 2008 for case number RG08-386432 for California Proposition 65 – Cal. Health & Safety Code §25249.5 et seq.

The product is designed to meet the stringent extractable metal requirements of NSF Standard 42 test protocol.

Technical Details & Test Data

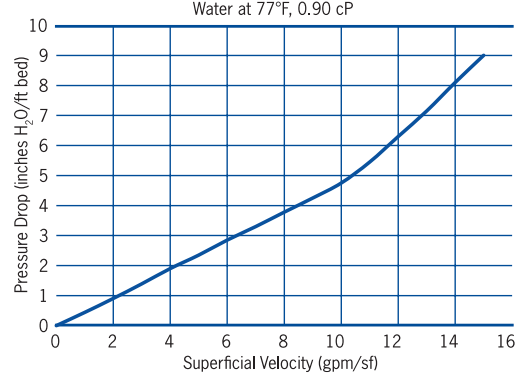

- Typical Pressure Drop

Based on a backwashed and segregated bed

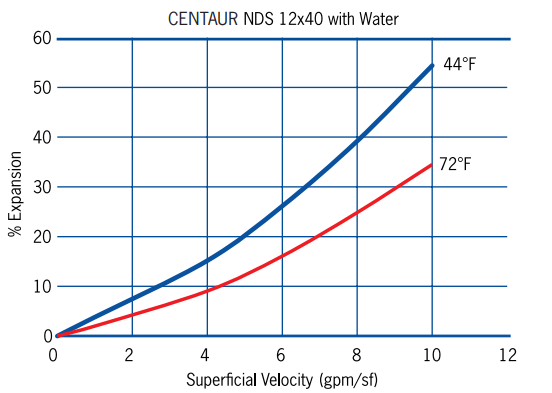

- Typical Bed Expansion During Backwash

- Design Considerations

CENTAUR NDS 12x40 is intended primarily for use in liquid phase applications where maximization of catalytic reaction is desired. Depending on the reactant type, concentrations and process conditions, the contact time in fixed bed systems is typically less than seven minutes.

Safety & Health

- Safety

Wet activated carbon can deplete oxygen from air in enclosed spaces. If use in an enclosed space is required, procedures for work in an oxygen deficient environment should be followed.