Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Carrier Resin

Polyolefinic

Features & Benefits

- Materials Features

- Highlights

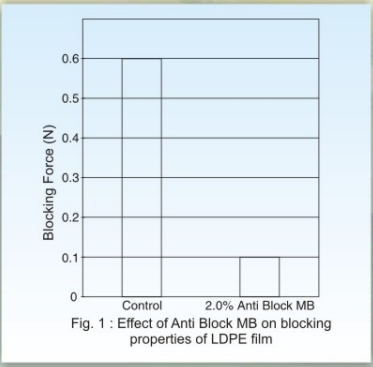

Blocking is a phenomenon where thin films especially those having smooth

surfaces without irregularities have a tendency to stick together when

stacked under pressure. This blocking can cause difficulties in handling

and processing of films. To overcome this problem, Anti block masterbatch

is added to film to reduce the tendency of blocking.

- Advantages

- Ensure good handling properties in automatic packaging application.

- Does not effect sealing and printing properties

- No effect on gloss and transparency.

- No health hazard

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Usage

1 3%. Start with 1% and adjust it as per requirement.

Properties

- Physical Form

- Appearance

- Translucent off white Granules

Packaging & Availability

- Packaging Type

- Packaging

Mono and Multilayer blown film for flexible packaging.

- Packaging

Material is packed in HDPE woven sacks of 25 Kgs.