Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Carrier Resin

Polyolefin

Features & Benefits

- Materials Features

- Highlights

Foaming agents are the additives which evolve gas through chemical reactions or through

thermal decomposition. This gas creates cell structure in the polymer matrix. Foaming agents

are of two types, Exothermic blowing agent and Endothermic blowing agent.- Properties

Very fine closed cell structure

Better surface appearance

Direct dosage in final formulation- Recommended Temperature

190- 220 degree centigrade

- Benefits

- Reduce Weight Strength ratio

- Improve rigidity

- Thermal Insulation

- Excellent Impact Strength

Applications & Uses

- Markets

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Usage

1-5% of the weight of foamed /middle layer

Properties

- Physical Form

- Appearance

- Yellow polymeric pulverized powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Bulk Density | 0.572 | gm/cc | - |

| Foaming Temperature (In Hot Air Oven) | 200.0 | °C | - |

| Moisture Content | max. 0.02 | % | - |

Technical Details & Test Data

- Comparison Between Foaming Agent and Master Batches

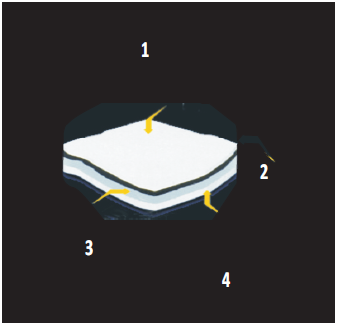

Tank Size Standard Weight Foam Layer In kgs Blowing Chemical Blowing Master Batch In Ltrs In Kgs 1% 1.50% 4 Layer White Tank 3rd MG 300LTRS 4 LAYER WHITE 24 5 0.05 0.075 500LTRS 4 LAYER WHITE 32 7 0.07 0.105 800LTRS 4 LAYER WHITE 38 8 0.08 0.12 1000LTRS 4 LAYER WHITE 46 8 0.08 0.12 1500LTRS 4 LAYER WHITE 73 15 0.15 0.225 2000LTRS 4 LAYER WHITE 87 17 0.17 0.255 2500LTRS 4 LAYER WHITE 102 20 0.2 0.3 3000LTRS 4 LAYER WHITE 125 26 0.26 0.39 5000LTRS 4 LAYER WHITE 202 40 0.4 0.6 1 (Outer / First Layer) White color polyethylene layer (UV stabilized). 2 (Second Layer) Black color second layer

same as last layer.3 (Third Layer) Polyethylene foam layer

Thermal Insulat ion &

rigidity4 (Inner /Fourth) White Layer containing Anti

fungus/Ant i bacter ial

master batch.

Packaging & Availability

- Packaging Type

- Packaging

Material is packed in 20 kg HDPE Woven Sacks