Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

Features & Benefits

- Base Chemicals Features

- Features

- High strength parts - without oil quenching, induction hardening or other post-sintering heat treatments (with or without tempering).

- Microstructure control - for optimum properties in parts of all sizes.

- It is possible to obtain P/M parts with high strength and hardness with a conventional sintering furnace without post-sintering treatment.

- Benefits

- Lower production costs.

- More environmentally friendly.

- Elimination of quench distortion.

- Large parts with tight tolerances become possible.

Applications & Uses

- Markets

Properties

- Physical Form

- Typical Properties

- Density*

Density measured in water.

| Value | Units | Test Method / Conditions | |

| Carbon | 0.01 | wt% | - |

| Oxygen | 0.25 | wt% | - |

| Sulfur | 0.009 | wt% | - |

| Phosphorus | 0.012 | wt% | - |

| Manganese | 0.45 | wt% | - |

| Molybdenum | 1.0 | wt% | - |

| Nickel | 0.9 | wt% | - |

| Silicon | 0.015 | wt% | - |

| Chromium | 0.45 | wt% | - |

| Iron | min. 97 | wt% | - |

| Apparent Density | 2.92 | g/cm³ | - |

| Flow | 26.0 | s/50g | - |

| Density* (600MPa) | 6.9 | g/cm³ | - |

Technical Details & Test Data

- Sinter Hardening

As Sintered : Atomet 4701 + 2% Cu + 1.0% C, 540 g piece, sintered 25 minutes at 1120°C, slow cooled at 0.4°C/s

Sinter Hardening:

- Sinter hardening is a cost-effective process where P/M parts are cooled in production sintering furnace at a rate that transforms the microstructure from austenite into martensite.

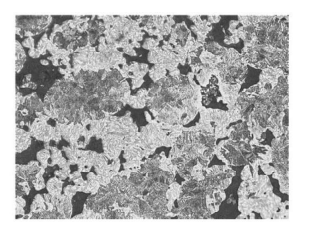

- Micrograph illustrates centrally located microstructure in a 540 g part slow cooled at 0.4ºC/s. Under controlled conditions, hardness of 30 HRC has been achieved throughout the part.

It is Achieved By:

- Atomet 4701 requires cooling rates of 0.4ºC to 1.5ºC/s, when cooling from 650ºC (1200ºF) through 400ºC (750ºF).

- Relative quantities of martensite and bainite may be tailored by adjusting the cooling rate and the added graphite and copper.

- Particle Size Analysis

Particle Size Analysis, wt% U.S. Mesh

µm+60 +100 +325 -325 +250 +150 +45 -45 Trace 12 67 21