Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Structural Characteristics

Features & Benefits

- Labeling Claims

- Materials Features

- General Advantages

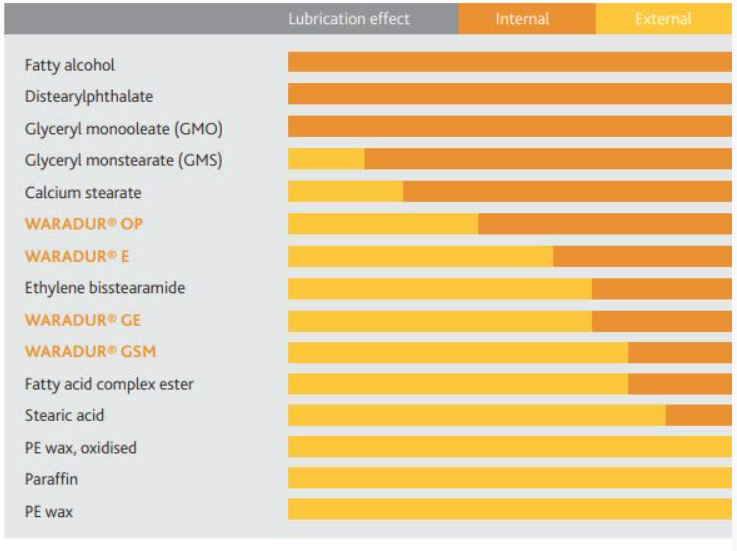

High effectiveness at low concentrations: WARADUR® GE is extremely versatile and suitable for a wide range of plastics applications as a multi-purpose additive, e.g. release agent, flow improver, dispersing agent, gloss booster, surface improver. WARADUR® GE is suitable for engineering plastics, thermosets, PVC, etc.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Recommended Application Areas

- Thermoplastics: PA, PBT, TPE, PET, PC, PVC, styrenics

- Thermosets: epoxy resins, phenolic resins, polyurethane

- Dispersing agents for color masterbatches and filled plastics (talc, glass fiber)

- Application Examples

Thermosets & Epoxides

Montan waxes combine internal lubrication with strong release. Therefore, they are also suitable for the processing of thermosets like epoxy resins and phenolic resins (Novolacs). Internal lubrication helps to improve flow properties whilst external lubrication reduces the adhesion of the molding compound to hot machine parts and improves mold release.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Acid Value | 13 - 30 | mg KOH/g | ISO 2114 |

| Viscosity (120°C) | 15 - 30 | mPa.s | AA 3.2.1.520 |

| Density | 1.00 - 1.02 | g/cm³ | Ph. Eur. 2.2.5 |

| Drop Point | 80 - 88 | °C | ASTM 3954 |

| Saponification Value | 130 - 165 | mg KOH/g | ISO 3681 |

Regulatory & Compliance

- Certifications & Compliance

- Legislation

Food contact legislation :

- FDA 175.105 Adhesives ("montan wax")

- FDA 177.2600 Rubber articles intended for repeated use ("montan wax")

- Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food

Other legislation :

- REACH, RoHS and CONEG compliant

- Listed in all relevant national inventories

Safety & Health

- Product Safety

WARADUR® GE

- is made from fossilized plant wax

- based on data from similar montan ester waxes: expected to REACH the criteria for inherent biodegradability (OECD Guideline 301 D, Closed Bottle Test)

- is not classified as carcinogenic, mutagenic or reprotoxic; no health or environmental hazards are known, provided it is applied in industrial and professional settings

Packaging & Availability

- Packaging

- Paper bag

- Big Bag

Storage & Handling

- Storage

Store at ambient temperature on a dry place. Protect from heat/overheating and direct sunlight. The maximum shelf life is 5 years after production. Thereafter, tests of the chemical characteristics are recommended. After delivery, a minimum remaining shelf life at the customer of 1.5 years is warranted.