Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

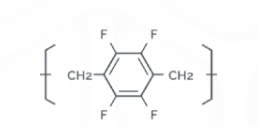

- Structure

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Application Method

- Coating Type

- Uses

Parylene N is the best choice for:

- Dry lubricity.

- High frequency/RF applications because of its low dissipation factor at high frequencies.

- Applications that require a higher penetration factor.

Properties

- Flame Rating

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Film Properties

- Electrical Properties

- Chemical Resistance

| Value | Units | Test Method / Conditions | |

| Coefficient of Friction (static and dynamic) | 0.25 | - | - |

| % Elongation to Break | 20 - 250 | % | - |

| Young’s Modulus | 2.4 | GPa | - |

| Tensile Strength | 48.3 | MPa | - |

| Yield Strength | 42.1 | MPa | - |

| Elongation to Break | 20 - 250 | % | - |

| Elongation at Yield | 2.5 | % | - |

| Density | 1.11 | g/cm³ | - |

| Hardness | R85 | Rockwell | - |

| Hardness | R85 | - | Rockwell |

| Coefficient of Friction (Static) | 0.25 | - | - |

| Coefficient of Friction (Dynamic) | 0.25 | - | - |

| Value | Units | Test Method / Conditions | |

| Gas Permeability (Oxygen at 25°C) | 3 | cc*mm/m²*day*atm | - |

| Penetration Power | 40 X | - | - |

| USP Class VI Polymer | Yes | - | - |

| Gas Permeability (Nitrogen at 25°C) | 3 | cc*mm/m²*day*atm | - |

| Gas Permeability (Carbon Dioxide at 25°C) | 84.3 | cc*mm/m²*day*atm | - |

| Gas Permeability (Hydrogen at 25°C) | 212.6 | cc*mm/m²*day*atm | - |

| Value | Units | Test Method / Conditions | |

| Short Term Service Temperature (in oxygen environments) | 95 | °C | - |

| Continuous Service Temperature (in oxygen environments) | 60 | °C | - |

| Short Term Service Temperature (in inert environments) | 265 | °C | - |

| Continuous Service Temperature (in inert environments) | 220 | °C | - |

| Linear Coefficient of Thermal Expansion (at 25° C) | 69 | ppm/°C | - |

| Thermal Conductivity (at 25° C) | 0.126 | W/m*K | - |

| Specific Heat | 0.2 | cal/g*°C | - |

| Melting Point | 420.0 | °C | - |

| Melting Point | 420 | °C | - |

| Short-term Service Temperature (Oxygen Environment) | 95.0 | °C | - |

| Short-term Service Temperature (Inert Environment) | 265.0 | °C | - |

| Continuous Service Temperature (Oxygen Environment) | 60.0 | °C | - |

| Continuous Service Temperature (Inert Environment) | 220.0 | °C | - |

| Linear Coefficient of Thermal Expansion (25°C) | 69.0 | ppm/°C | - |

| Thermal Conductivity (25°C) | 0.126 | W/mK | - |

| Specific Heat (20°C) | 0.2 | cal/g°C | - |

| Value | Units | Test Method / Conditions | |

| Nitrogen Gas Permeability (25°C) | 3.0 | (ccxmm)/(m²xdayxatm) | - |

| Oxygen Gas Permeability (25°C) | 15.4 | (ccxmm)/(m²xdayxatm) | - |

| Carbon Dioxide Gas Permeability (25°C) | 84.3 | (ccxmm)/(m²xdayxatm) | - |

| Hydrogen Gas Permeability (25°C) | 212.6 | (ccxmm)/(m²xdayxatm) | - |

| Value | Units | Test Method / Conditions | |

| Dielectric Strength (25.4microns) | 276.0 | V/micron | - |

| Dielectric Strength (0.001”) | 25.4 | V/mil | - |

| Volume Resistivity (23°C, 50% RH) | 1.4x10¹⁷ | ohm-cm | - |

| Surface Resistivity (23°C, 50% Relative Humidity) | 1x10¹³ | ohms | - |

| Dielectric Constant (60Hz) | 2.65 | - | - |

| Dielectric Constant (1KHz) | 2.65 | - | - |

| Dielectric Constant (1MHz) | 2.65 | - | - |

| Dielectric Constant (6GHz) | 2.54 | - | - |

| Dielectric Strength (at 0.001”) | 7 | KV/mil | - |

| Dissipation Factor (60Hz) | 0.0002 | - | - |

| Dissipation Factor (1KHz) | 0.0002 | - | - |

| Volume Resistivity (at 23°C, 50% RH) | 1.4x10¹⁷ | ohm-cm | - |

| Dissipation Factor (1MHz) | 0.0006 | - | - |

| Surface Resistivity (at 23°C, 50% Relative Humidity) | 1x10¹³ | ohms | - |

| Dissipation Factor (6GHz) | 0.0021 - 0.0028 | - | - |

| Dielectric Constant (at 1MHz) | 2.65 | - | - |

| Dissipation Factor (at 1MHz) | 0.0006 | - | - |

| Value | Units | Test Method / Conditions | |

| Hydrochloric Resistance (10%, Non-Oxidizing Acid, 25°C) | 0.0 | % | - |

| Hydrochloric Resistance (10%, Non-Oxidizing Acid, 75°C) | 0.0 | % | - |

| Hydrochloric Resistance (37%, Non-Oxidizing Acid, 25°C) | 0.2 | % | - |

| Hydrochloric Resistance (37%, Non-Oxidizing Acid, 75°C) | 2.3 | % | - |

| Sulfuric Resistance (10%, Non-Oxidizing Acid, 25°C) | 0.1 | % | - |

| Sulfuric Resistance (10%, Non-Oxidizing Acid, 75°C) | 0.2 | % | - |

| Sulfuric Resistance (95 - 98%, Non-Oxidizing Acid, 25°C) | 0.2 | % | - |

| Sulfuric Resistance (95 - 98%, Non-Oxidizing Acid, 75°C) | 5.3 | % | - |

| Nitric Resistance (10%, Non-Oxidizing Acid, 25°C) | 0.1 | % | - |

| Nitric Resistance (10%, Non-Oxidizing Acid, 75°C) | 0.2 | % | - |

| Nitric Resistance (71%, Non-Oxidizing Acid, 25°C) | 0.2 | % | - |

| Nitric Resistance (71%, Non-Oxidizing Acid, 75°C) | Brittle | - | - |

| Chromic Resistance (10%, Non-Oxidizing Acid, 25°C) | 0.1 | % | - |

| Chromic Resistance (10%, Non-Oxidizing Acid, 75°C) | 1.2 | % | - |

| Chromic Resistance (74%, Non-Oxidizing Acid, 25°C) | 0.3 | % | - |

| Chromic Resistance (74%, Non-Oxidizing Acid, 75°C) | 8.2 | % | - |

| Sodium Hydroxide Resistance (10%, Base, 25°C) | 0.1 | % | - |

| Sodium Hydroxide Resistance (10%, Base, 75°C) | 0.0 | % | - |

| Ammonium Hydroxide Resistance (10%, Base, 25°C) | 0.3 | % | - |

| Ammonium Hydroxide Resistance (10%, Base, 75°C) | 0.4 | % | - |

| De - Ionized Water Resistance (100%, Inert, 25°C) | 0.0 | % | - |

| De - Ionized Water Resistance (100%, Inert, 75°C) | 0.0 | % | - |

| Isopropyl Resistance (Alcohol, 25°C) | 0.3 | % | - |

| Isopropyl Resistance (Alcohol, 75°C) | 0.3 | % | - |

| Iso - Octane Resistance (Aliphatic Hydrocarbon, 25°C) | 0.2 | % | - |

| Iso - Octane Resistance (Aliphatic Hydrocarbon, 75°C) | 0.3 | % | - |

| Pyridine Resistance (Amine, 25°C) | 0.2 | % | - |

| Pyridine Resistance (Amine, 75°C) | 0.4 | % | - |

| Xylene Resistance (Mixed, 25°C) | 1.4 | % | - |

| Xylene Resistance (Mixed, 75°C) | 2.1 | % | - |

| Trichloroethylene Resistance (TCE, 25°C) | 0.5 | % | - |

| Trichloroethylene Resistance (TCE, 75°C) | 0.7 | % | - |

| Chlorobenzene Resistance (Chlorinated Aromatic, 25°C) | 1.1 | % | - |

| Chlorobenzene Resistance (Chlorinated Aromatic, 75°C) | 1.7 | % | - |

| O-Dichlorobenzene Resistance (Chlorinated Aromatic, 25°C) | 0.2 | % | - |

| O-Dichlorobenzene Resistance (Chlorinated Aromatic, 75°C) | 0.3 | % | - |

| Trichlorotrifluoroethane Resistance (Fluorocarbon, 25°C) | 0.2 | % | - |

| Trichlorotrifluoroethane Resistance (Fluorocarbon, 75°C) | 0.2 | % | - |

| Acetone Resistance (Ketone, 25°C) | 0.3 | % | - |

| Acetone Resistance (Ketone, 75°C) | 0.4 | % | - |

| 2,4-Pentanedione (Ketone, 25°C) | 0.6 | % | - |

| 2,4-Pentanedione (Ketone, 75°C) | 0.7 | % | - |

Regulatory & Compliance

- Certifications & Compliance