Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Benefits

Unique combination of benefits from cotton barriers made using Alexiflam® NF

Alexium is proud to introduce you to Alexiflam® NF, the latest fire-retardant technology for use in mattress applications. In addition to passing the stringent regulatory requirements, Alexiflam® NF is a sustainable solution that eliminates health risks from airborne fiberglass shards and is durable to liquid spills.

- Fire Protection

- Consumer health

- Durability

- Sustainable materials

- Cost advanced

- Cost Advantaged

Cotton socks treated with Alexiflam® NF are not only differentiated by health and sustainability features, they also cost less than socks made from the synthetic alternatives. While competitors start with highly tailored and highcost specialty materials, Alexiflam® NF socks use widely available and lower-priced commodity cotton which is significantly less expensive. So even after treatment with Alexiflam® NF, the sock is more affordable. This means that sock and mattress manufacturers can protect consumers and the environment while improving their bottom line.

- Additional Advantages

- Design flexibility: With Alexium technology, our customers are not limited to a specific design or knitting pattern. Alexiflam® NF can transform cotton fabrics into effective barriers.

- Supply preference: It’s the preferred choice of many suppliers who can produce cotton socks

Applications & Uses

- Markets

- Compatible Reinforcements

- Fire Protection

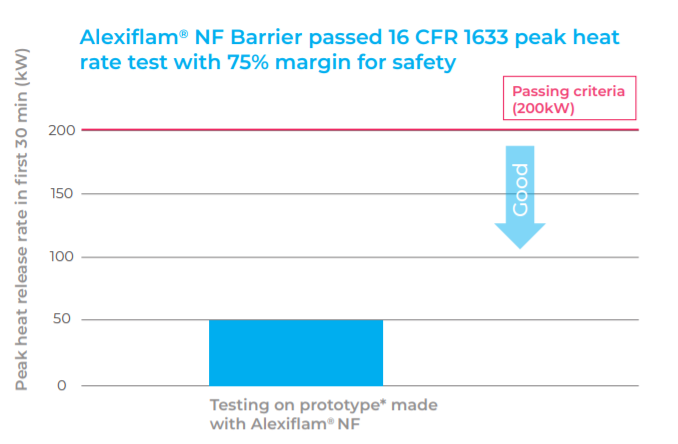

Flame-retardant materials are used in many consumer and industrial products to help prevent and slow fires, protect property, and most importantly save lives. Foam mattresses require a flame-retardant barrier in order to pass regulatory requirements designed to protect consumers. As regulated by the United States Consumer Product Safety Commission, our prototype foam mattresses using FR barriers treated with Alexiflam® NF passed the rigorous flammability testing (16 CFR 1633). Underwriter Laboratories (UL), an independent third party, conducted the testing with the impressive outcomes indicated in the charts below.

- *100% cotton prototype bed construction Sock composition:

- 100% Cotton, 220gsm, rib

- Mattress size: 12” memory foam

- Ticking: PCM-treated polyester

- UL test method: 16 CFR Part 1633

- Sustainable Materials

Current products use non-sustainable synthetic fabrics and non-renewable materials, such as rayon, modacrylic, and fiberglass. Rayon is created by altering cellulose using carbon disulfide, a chemical with acute health risks. Modacrylic is produced from petroleum based raw materials. And fiberglass is produced using non-renewable minerals and is manufactured using an energy intensive process. These methods are less than ideal solutions for safety, health or the environment.

Alexiflam® NF treats natural and sustainable 100% cotton, an environmentally-friendly fiber that is a renewable and biodegradable resource.

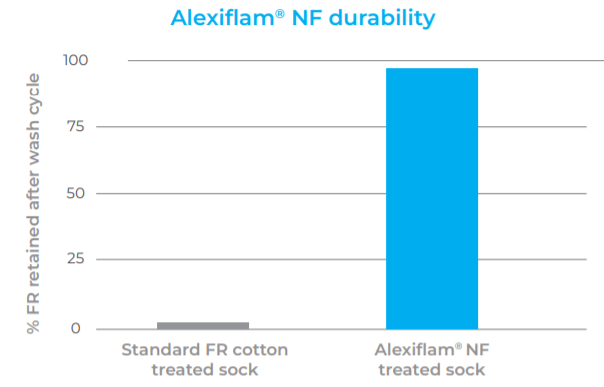

- Durability

Many factors affect the life span of a mattress with the most visible signs when they get wet from spilled coffee or perspiration when sleeping. Traditional cotton treatments are water soluble and wash away with spills, leaving the sock with inadequate flameretardant protection and putting families at risk. Alexiflam® NF treated socks are durable to water, so you can rest assured that a spill does not leave consumers unprotected. To demonstrate its durability, we simulated a liquid incident test by soaking a cotton sock fabric treated with Alexiflam® NF for one minute. The fabric retained 98% of the FR product. A standard FR treated cotton sock retained less than 2% of the treatment, losing its FR properties and leaving consumers unprotected.

Consumers can rest assured when you supply them a mattress that uses a cotton sock treated with Alexiflam® NF.

Technical Details & Test Data

- Comparison of Alexiflam® NF treated cotton sock to alternatives

Standard FR treated cotton sock Fiberglass/Rayon sock Alexiflam® NF treated cotton sock

Flame Retardant Yes Yes Yes Consumer safety and health No (Flame Retardant can Wash Off) No (Airboene Fiberglass Shards) Yes Sustainable fabric Yes No Yes

Safety & Health

- Consumer Health

While consumers sleep, FR socks with fiberglass pose no special health risks. But sometimes families move mattresses from room to room or house to house. And other times children bounce on a mattress. This causes unusual stresses which can tear the FR barrier and tiny shards of glass become airborne leading to respiratory and skin irritation. In some cases reported in the press, families were compelled to leave home while their entire houses were remediated to remove fiberglass shards that had migrated from their bedrooms into the ventilation system and dispersed through the house. Using cotton socks treated with Alexiflam® FR avoids this problematic scenario altogether.