Knowde Enhanced TDS

Identification & Functionality

- Base Chemicals Functions

- Technologies

- Product Families

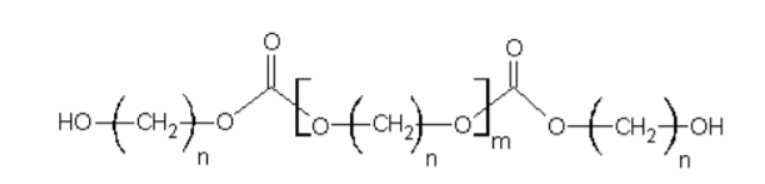

- Structure

Ravecarb 106: n=50% 6; 50% 5; m=12

Features & Benefits

- CASE Ingredients Features

- Features

Superior Resistance to

- Temperature

- Hydrolysis

- Degradation by Ultraviolet Light

- Oxygen

- Solvents

Tensile strength Excellent Heat stability Excellent Weather ability Excellent Hydrolysis resistance Excellent Fungi resistance Good Oleic acid resistance Excellent

Applications & Uses

- Markets

- Base Chemicals End Uses

- Uses

- Polyurethane coatings suitable for special uses, high resistance to hydrolysis, heat, U.V., radiation and atmospheric agents, high modulus and high mechanical resistance.

- Used in adhesives, synthetic leather, paints and varnishes, thermoplastics

- General Formulations

Properties

- Physical Form

- Appearance

- White solid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Chemical Structure | Homopolymer from hexandiol | — | — |

| Theoretical OH Functionality | 2.0 | — | — |

| OH number | 53 - 59 | mgKOH/g | — |

| Average Molecular Weight | 2000.0 | — | — |

| Acidity number | 0.1 | mgKOH/g | — |

| Water | 0.1 | % | — |

| Melting range | 36 - 50 | °C | — |

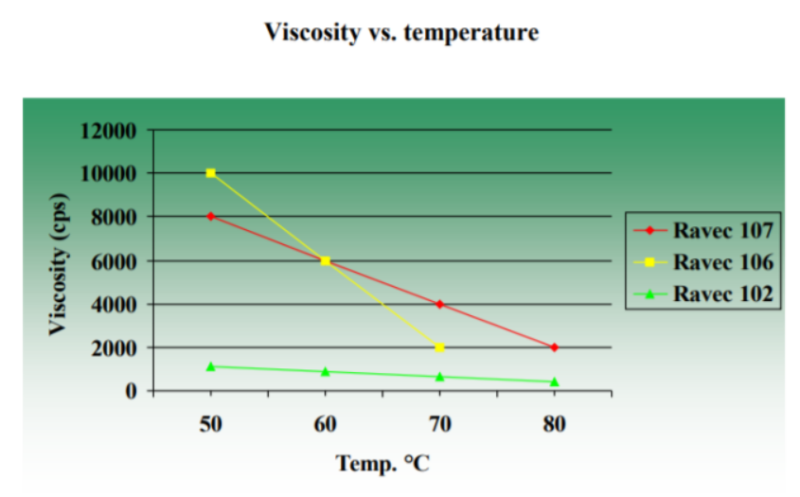

| Viscosity (50°C) | 10000.0 | cps | — |

| Tensile strength (Aliphatic PUR) | 62.1 | N/nm | — |

| Section Modulus (100%, Aliphatic PUR) | 10.2 | — | — |

| Elongation (Aliphatic PUR) | 1009.0 | % | — |

| Tensile strength (Aromatic PUR) | 61.6 | N/nm | — |

| Section Modulus (100%, Aromatic PUR) | 9.3 | — | — |

| Elongation (Aromatic PUR) | 1200.0 | % | — |

Technical Details & Test Data

- Viscosity vs Temperature

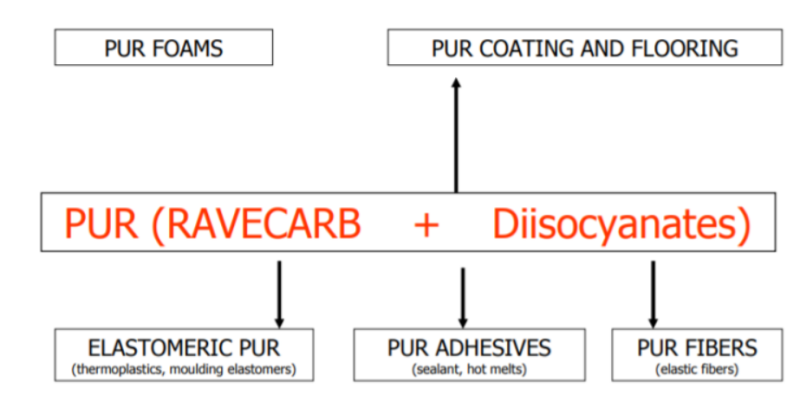

- Ravecarb and Elastomeric “PUR”

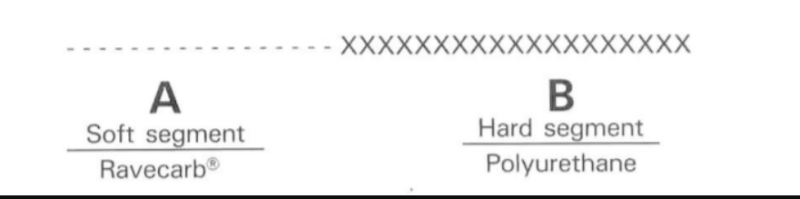

A urethane polymer is the reaction product of a high molecular weight polyol, a short difunctional chain extender, and an aliphatic or aromatic diisocyanate (here is no difference in the formulation technique between Ravecarb and polyols of different natire). It produces a (AB) type polymer composed of alternating hard and soft segment:

The soft segment is the high molecular weight polyol chain, and the hard segment is the reaction product of the chain extender and the diisocyanate. As the concentration of the hard segment increases, the modulus of the urethane increases, and the opposite when the soft segment increases. In addition, the nature of the hard segment can be modified by the choice of an appropriate crosslinker.

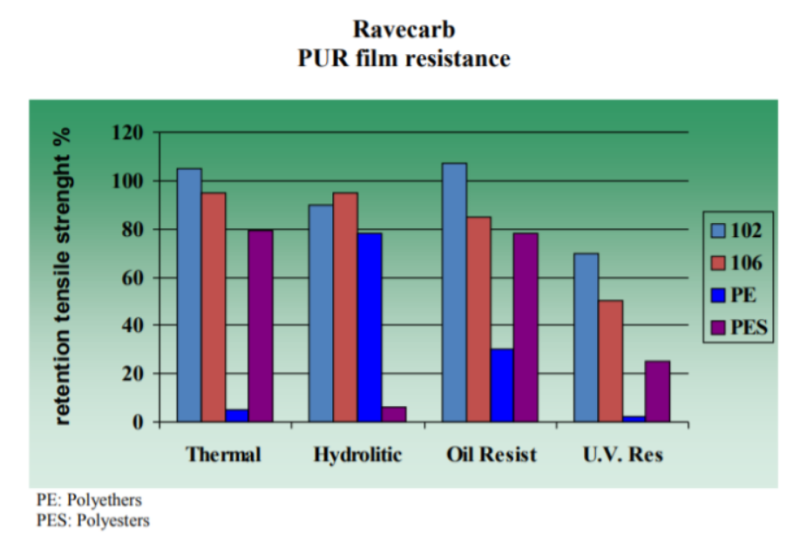

- Ravecarb PUR film resistance

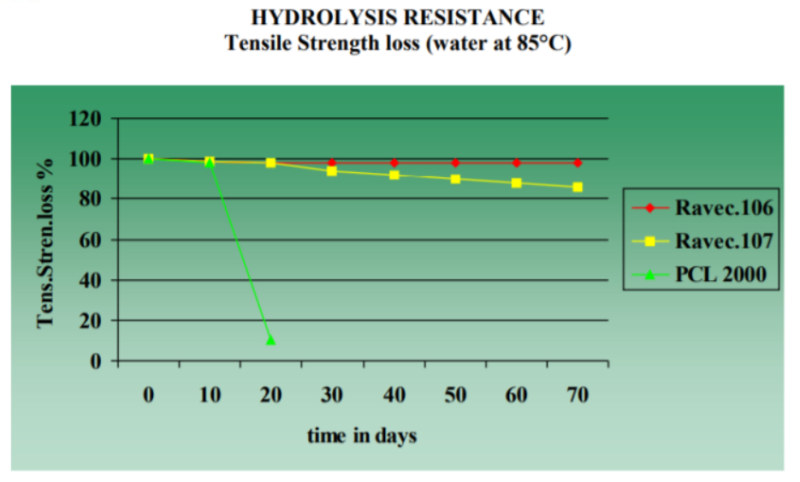

- Hydrolysis Resistance Tensile Strength Loss (water at 85°C)

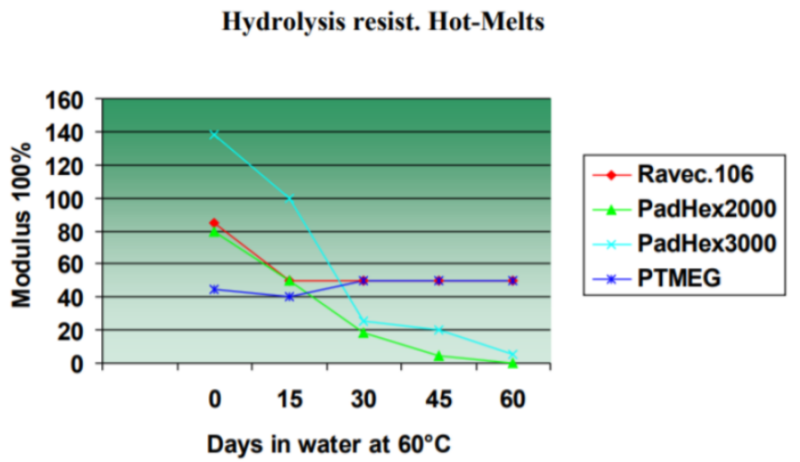

- Hydrolysis resist. Hot-Melts