Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Foam Type

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Features

- Low viscosity

- Fast room temperature cure

- Low smoke, flame, and toxicity upon combustion

- Primerless chemical adhesion at room temperature to many substrates

Applications & Uses

- Markets

- Applications

- Application Area

- Cure Method

- Application

- Lightweight potting and encapsulation

- EV battery modules

- PCB staking

- Insulation

Use and Cure Information

Important:

- In order to achieve optimum performance, the same lot number of the A and B components should be used. Mixed lots may not obtain the performance criteria listed on the TDS or Certificate of Analysis.

- The 'A' part of the product contains the platinum catalyst; great care should be taken when using automatic dispensing equipment. Please ensure that it is not contaminated by residual hydride containing rubber (Part B) in the dispensing equipment, as curing will result. If in doubt, it is advised to thoroughly purge the equipment with a suitable hydrocarbon solvent or silicone fluid.

Mixing

- This product is designed to be dispensed by volume and mixed via static mixer. It is best practice to ensure both components are uniform by stirring, if necessary, prior to dispense and use of the product.

- This silicone foam product was designed to be forgiving and process friendly. Depending on the desired flow rate of the dispense system, the static mixer used will influence foam quality. For example, dispensing through a square (8 mm by 8 mm) 32 element static mixer at 1-2 grams per second can result in high quality foam structure. Other mixer configurations may also provide good foam quality, and testing is suggested with regards to equipment-type and application. If foam cell/density quality is not to expectation, changing the dispense conditions to allow for less or greater residence time in the static mixer can influence cell structure via either dispense rate or static mixer configuration.

Temperature

The ambient temperature of the environment, bulk silicone formulation, dispense equipment, and part in which the foam will be dispensed will influence the quality (cell structure and density) of the foam. Reaction (blowing and gelation) slow as temperature is decreased and speed-up as the temperature is increased. Ideal dispensing temperature is from 20 - 30 °C (68 - 85 °F).

Expansion

The silicone foam product will expand by a factor of two to three times the nominal dispense volume via generation of hydrogen gas. The blowing and gelation reactions take place simultaneously upon mixing Parts A and B. When potting an enclosed container, it should be noted that the combined reactions of gelation and blowing may result in exterting pressure on the housing and components inside. The volume and rate of dispense will affect the overall density and cell structure.

Processing and Purging

Due to the fast gel time, machine dispense is recommended. Ideally, the silicone foam is dispensed in or on the parts quickly in succession. If there is to be a gap in time between dispense stages, a purge cycle is recommended to clear the nozzle. To prevent curing in the mixer and equipment, a minimum recommended gap between dispenses or purges is approximately one-fourth of the stated gel time (i.e., if gel time is 120 seconds, a purge or dispense should take place within 30 seconds). The time and frequency in which purges are needed will be dependent on environmental conditions.

Inhibition of Cure

Great care must be taken when handling and mixing all addition cured silicone elastomer systems, ensuring that all the mixing tools (vessels and spatulas) are clean and constructed in materials which do not interfere with the curing mechanism. The cure of the silicone can be inhibited by the presence of compounds of nitrogen, sulfur, phosphorus and arsenic; organotin catalysts and PVC stabilizers; epoxy resin catalysts and even contact with materials containing certain of these substances e.g. molding clays, sulfur vulcanized rubbers, condensation cure silicone rubbers, onion and garlic.

Properties

- Cured Properties

- Uncured Properties

- Uncured Product Property

Color A Black Color B Translucent white Mix Ratio By Volume 1 to 1 Mix Ratio By Weight 1.17 to 1 Self Bonding Yes

| Value | Units | Test Method / Conditions | |

| Elongation (at Break) | 70.0 | % | ISO 37 |

| Foam Density | 0.4 | g/cc | — |

| Working Temperature | max. 200 | °C | — |

| Thermal Conductivity | 0.067 | W/mK | — |

| Value | Units | Test Method / Conditions | |

| Gel Time (at 25°C) | 90.0 | Seconds | — |

| Specific Gravity (Component A) | 1.17 | — | — |

| Specific Gravity (Component B) | 1.0 | — | — |

| Viscosity (Component A) | 20000.0 | cP | Brookfield |

| Viscosity (Component B) | 12000.0 | cP | Brookfield |

| Viscosity (Mixed) | 17000.0 | cP | Brookfield |

Technical Details & Test Data

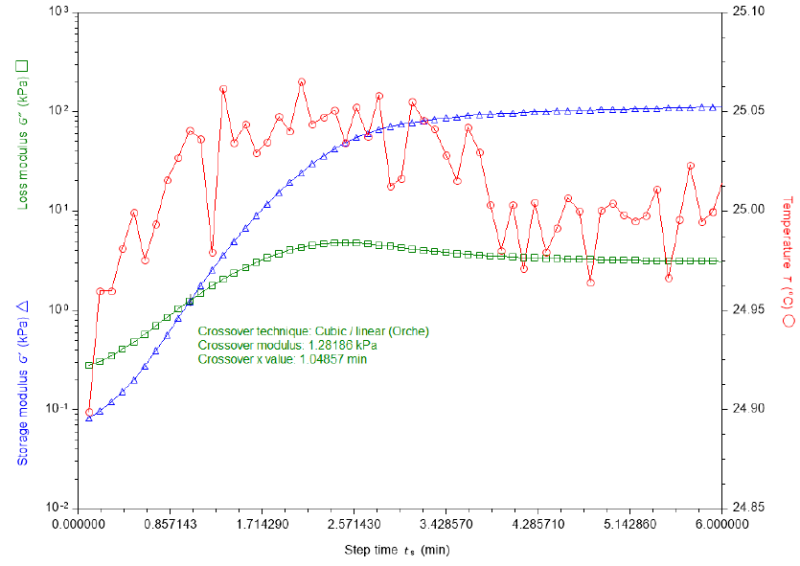

- Cure & Modulus Behavior of SilSo Lite 21025

The below table illustrates the cure behavior of the foam at various temperatures. An example rheology curve at 25 °C is below. The start time of the experiment is approximately 1 minute after dispense.

Temperature (°C) Temperature (°F) Time to Modulus Crossover (min) 1.0 33.8 18.7 5.0

41.0 10.1 9.0 48.2 7.8 13.0 55.4 4.8 17.0 62.6 2.7 21.0 69.8 1.7 25.0 77.0 1.0 SilSo Lite 21025 Cured Isothermally at 25 °C

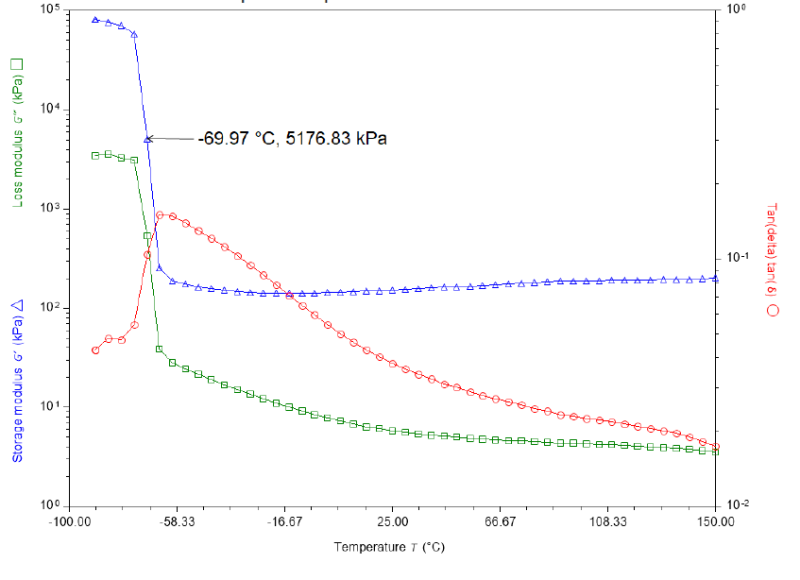

Modulus versus temperature profile for SilSo Lite 21025 from -90 °C to 150 °C

Safety & Health

- Health and Safety

Proper storage and handling are required. The Part B component can evolve hydrogen over time. It is important to avoid contact with acids and bases during storage. Product should be used in a well ventilated area during dispense.

Packaging & Availability

- Packaging Type

- Packaging

CHT silicone liquid foams are available in a variety packaging including bulk containers.

Storage & Handling

- Shelf Life

- 6 Months

- Storage Conditions

Maximum storage temperature is 38 °C / 100 °F