Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

Applications & Uses

- Applications

- Applications & Uses

Application area and materials

For common European woods and wood materials, synthetics, stone, ceramics, metals, insulating materials, concrete and non-flammable building boards. For tropical timber and woods with a high content of ingredients, we recommend performing bonding tests. For applications in exposed areas it is essential to seek clarification on the parts’ intended use and to perform bonding tests.

Application data

The curing behavior of 1C PUR adhesives depends on the moisture content and temperature of the adherends and the ambient climate. The figures are based on results of tests on precision bonds (wood moisture content 12%) made under standard conditions (20 °C and 65% relative humidity). Different conditions may lead to deviations from the said specifications.

Application

It is essential that the surfaces are clean and grease-free in order to provide the best adhesion and quality of join. Apply the adhesive directly from the container and spread using the appropriate Collano spatula. When applying from plastic tank, follow the Collano Easy Applico 1000 operating instructions. The adherends should first be conditioned to match the climatic conditions of the intended application area, before gluing.

Clean-up

Wipe off any splashes of liquid adhesive using Collano HP 3000, Collano HP 3100 or ethanol. Remove cured adhesive using Collano HP 3000

Preventing and blocking adhesion

Collano HP 2000 can prevent adhesion to equipment, tools and machinery.

Properties

- Color

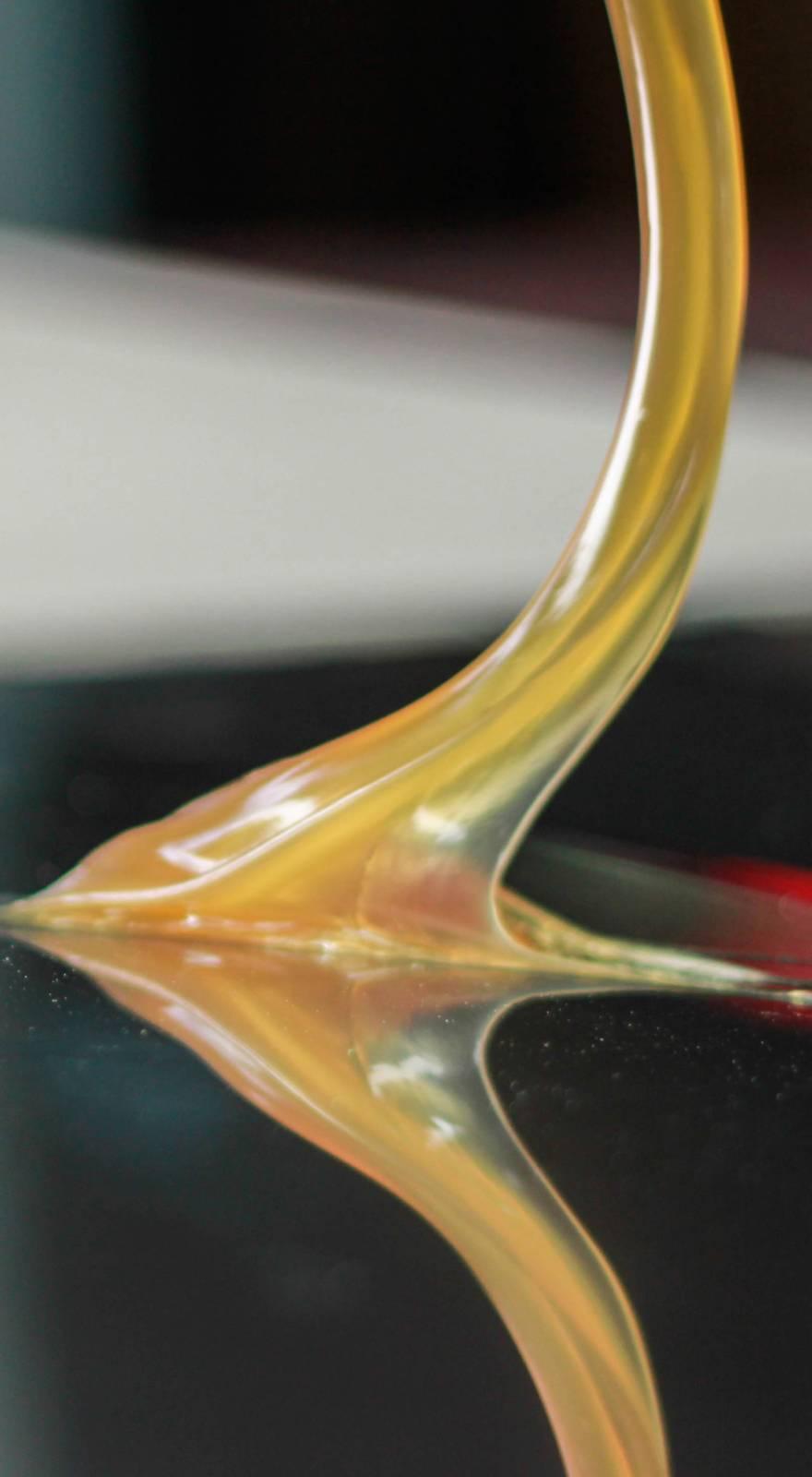

- Physical Form

- Appearance

- Liquid

- Typical Properties

- Adhesive Properties

| Value | Units | Test Method / Conditions | |

| Base | Polyurethane | - | - |

| Density | 1.25 | g/cm³ | - |

| Solids Content | 100.0 | % | - |

| Fluidity | Free flowing | - | - |

| Viscosity (Brookfield) | 8'000 - 12'000 | mPa·s | - |

| Pressure | 0.1 - 1.0 | N/mm² | - |

| Material Moisture Content | 6 - 18 | % | - |

| Application Temperature | 10 - 30 | °C | - |

| Maximum Open Assembly Time | max. 15 | minutes | - |

| Minimum Press Time | min. 45 | minutes | - |

| Final Strength | 7.0 | days | - |

| Value | Units | Test Method / Conditions | |

| Adhesive Application Quantity | 100 - 300 | g/m² | - |

Technical Details & Test Data

- Technical Details

Performance | Material Properties

Information derives from tests carried out by Collano.

Bond strength

- EN 12765, stress group C4.

Temperature resistance

- 120 °C at short-term temperature stability.

Fire resistance category

- EN 13501, provided the appropriate materials and constructions are used.

Resistance

- Resistant against weak caustics, acids and solvents.

Eco label

- EcoBasis, does not violate any Minergie-ECO exclusion criteria.

Safety & Health

- Safety & Health

Safety

The wearing of protective gloves and safety goggles is recommended while handling the liquid product.

Packaging & Availability

- Packaging Type

- Packaging

Packaging

- Plastic bottles 800 g

- Tin buckets 7.5 kg

Storage & Handling

- Storage

Storage

9 months in unopened original packaging at 15–25 °C.