Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 7782-42-5

- EC No.

- 231-955-3

- Technologies

- Product Families

- Composition

PowerFill takes our high density WonderFill and 100% encapsulates it with high purity nickel using the best possible materials and coating techniques. Thermal and electrical conductivity increase substantially with PowerFill. Product flexibility continues with our metal clad option.

Features & Benefits

- Materials Features

- Product Highlights

The nickel coating adheres to the graphite surface without voids and is uniform throughout the coating thickness so shielding effectiveness is maximized. After nickel coating, each particle is autonomous and the result is a free flowing, easy to process powder.

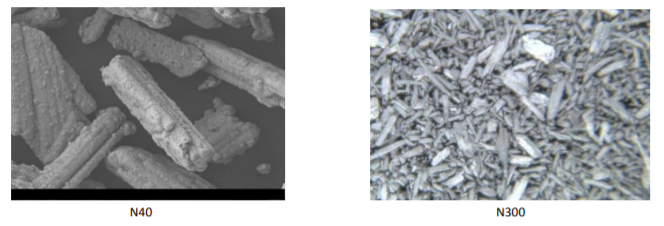

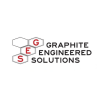

Two standard grades of PowerFill are available. The nickel-coated graphite fiber bundles have aspect ratios varying from 1:1 to 500:1. PowerFill N40 has a low aspect ratio with bulk density of 1550g/l, while the N300 has a higher aspect ratio with some longer particles being approximately 500:1 and a bulk density of 1650g/l. No sizings are applied to nickel surface.

Powerfill N300 has been compounded at 40% by weight addition in both thermoplastic polymers and elastomers to yield higher conductivity than competitive additives. The N40 product has also been compounded as high as 65% weight addition in nylon 6 to create a much more conductive compound. Competitive additives are limited in their loading to typically 40% or less due to processing parameters. All GES materials process effortlessly to allow higher production rates and loading percentages as compared to alternative additives.

Other PowerFill particle size distributions can be specified; as well other coating metals (copper, silver) can be considered.

- Extreme Performance

- Exceptional proven performance achieving less than 1/2 ohm resistance in compound.

- Outstanding corrosion resistant.

- High thermal conductivity

- High Electrical Conductivity

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

Properties

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- PowerFill-Nickel Coated Graphite Fiber Powder

Polymer Additive for EMI / RFI Shielding and Low Resistivity / High Conductivity Applications