Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Benefits

- Fast Drying/Increased Production Time

- Acrylic Modified Alkyd

- Can Be Cross Linked with 8000 Polyurethane Converter

- Excellent Gloss and Color Retention and Chalk Resistance

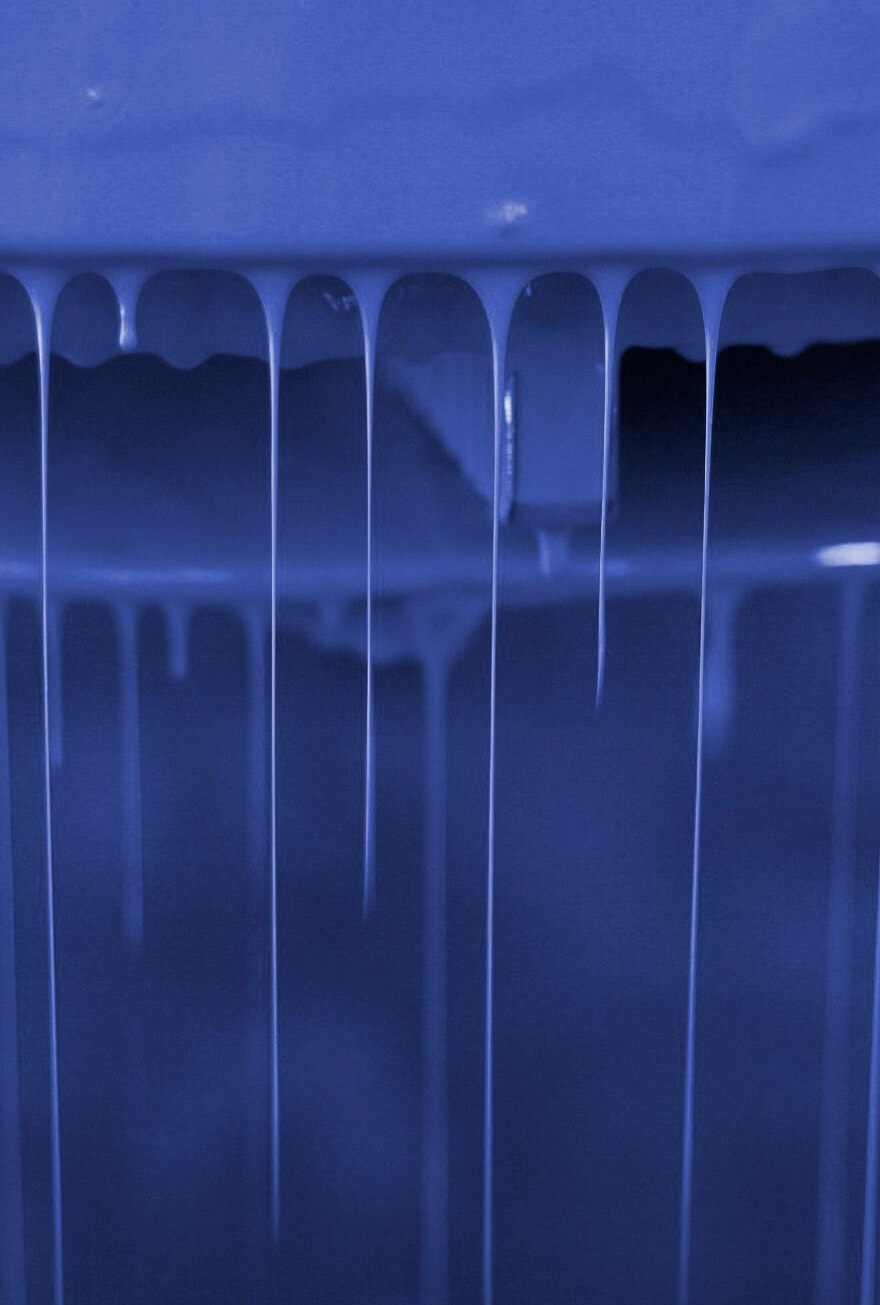

- Excellent Sag Resistance

- Excellent Adhesion

- Excellent Recoat

- Excellent Corrosion Resistance

- Excellent Hardness

- Excellent Resistance to U.V. Exposure

- Excellent Durability

- Good Abrasion Resistance/Resists Chipping

- High Hiding9

Applications & Uses

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Uses

Applications include OEM horse trailer, off-road construction equipment, farm machinery, livestock equipment, storage tanks, tractor-trailers and industrial finishing where both high performance and fast production on the paint line are required.

- Surface Preparation

All substrates must be cleaned free of dust, dirt, oil (including form oils & parting compounds), grease, soap residue, wax and flaking paint. Solvent wipe and/or detergent clean surface in accordance with SSPC-SP1. Sandblast or wire-brush rusty surfaces and prime with 92 Series Alkyd Primer. For optimum adhesion and corrosion resistance, metal should be iron or zinc phosphate treated. Refer to Surface Preparation Guide for more detailed instructions.

- Applications

- Mixing: Hand stir each container thoroughly before using and occasionally while applying. No thinning usually required. For thinning instructions, contact your local H-I-S sales representative.

- Application: May be applied by air, airless, air-assisted airless, turbo or HVLP spray. Product may also be applied by dip or flowcoat. Recommended tip size for airless or air assisted airless spray: .011” to .015” (0.28-0.38 mm) orifice.

- Cleanup: Clean spills, spatters, hands, tools and other equipment promptly with lacquer thinner. Dispose of used paint and waste in accordance with local, state and federal regulations. Follow manufacturer’s safety recommendations when using lacquer thinner.

- Application Precautions & Limitations: Apply when surface, air and product are above 40°F (4°C) and at least 5°F (3°C) above the dew point.

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Volatile Organic Compounds | 563 | g/l | EPA Method 24 |

| Vehicle Type | 4.71 | lb/gal | — |

| Weight Gallon | Acrylic Modified Alkyd | — | — |

| Weight Solids | 7.85 | lb/gal | — |

| Volume Solids | 40.5 | % | — |

| Gloss (at 60°) | 32.7 | % | — |

| Viscosity | 85 | ° | — |

| Hardness (at 77°F) | 65 - 70 | KU | — |

| Grind | B after 30 days | — | — |

| Flash Point | 43 | °F | — |

| Coverage (at 1 dry mil, 25 microns) | 558 | sq.ft./gal | — |

| Practical (11.2 m²/l) | 558 | sq.ft./gal | — |

| DFT (9-10 m²/l) | 450 - 500 | sq.ft./gal | — |

| Reduction & Cleanup (Dry (25 Mircrons), Toluol (Winter)) | 1 mil | — | — |

| Dry Time (at 70°F & 50% RH, To Touch) | 15 | Minutes | — |

| Dry Time (at 70°F & 50% RH, Hard) | 4 | Hours | — |