Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Product Type

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Applications

- Application Area

- Industrial Uses

Type

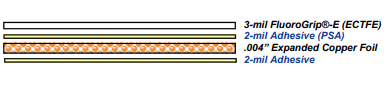

- LS-1000® – Is a high performance laminate applique system comprised of a 3 mil outer fluoropolymer film manufactured from ethylene-chlorotrifluoroethylene (Halar®*) and an underlying expanded copper foil sandwiched between 4-mil and 2-mil acrylic pressure sensitive adhesive designed for an easy peel-and-stick application.

- This applique product is designed to protect underlying composite surfaces from lightning with easy maintenance and repair features.

- LS 1000 has long term environmental resistance characteristics that allow it to be used in extreme outdoor environments including marine, desert and other severe locations. LS-1000® – provides excellent lightning protection to underlying substrates via a sacrificial mode that restricts most damage to the LS 1000® applique film.

- After damage LS-1000® can simply be removed and replaced to provide the same quality lightning protection that the original material provided.

- LS-1000® – is available standard with 3 mil FluoroGrip®-E, .004” expanded copper foil, and a new acrylic based pressure sensitive adhesive system developed for applications on supersonic aircraft.

- LS-1000® can also be customized to have a desired color, different gage, weight or specific metallic foil, and customized adhesive systems for applications that may require specifications outside the scope of the offered product.

Uses

- LS-1000® –applique films provides an excellent alternative to conventional embedded metallic foil composite materials used for constructing structures that are susceptible to lightning strikes. Current systems utilizing embedded metallic foils require costly maintenance and repair once the object incurs a lightning strike event.

- LS-1000® acts as a sacrificial surface layer that protects underlying composites from severe lightning strike damage and can then be easily repaired by simply removing the damaged area of the applique and replacing it with a new section. No bus bars or electrical reattachment is required.

- In addition, LS-1000® can provide desired esthetics (e.g., color), foul resistance, outstanding resistance to cleaning solvents, oils, fuels, (and other fluids or chemicals that may be systematic to the desired application), UV protection, and finally environmentally friendly corrosion and weathering protection of any underlying surface or structure.

Performance

- FluoroGrip® – LS-1000 film has outstanding resistance to chemicals, weathering and high-energy radiation.

Properties

- Flame Rating

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Electrical Properties

- Temperature Properties

- Adhesive Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength | 55.0 | MPa | ASTM D-882 |

| Elongation, Ultimate | 250.0 | % | ASTM D-882 |

| Tensile Modulus | 1375.0 | MPa | ASTM D-882 |

| Initial Tear Strength (1 mil) | 4.4 | N | ASTM D-1004 |

| Propagating Tear Strength (1 mil) | 11.6 | N | ASTM D-1922 |

| Fold Endurance (M.I.T.) | min. 250000 | cycles | ASTM D-2176 |

| Value | Units | Test Method / Conditions | |

| Specific Gravity | 1.68 | — | ASTM D-792 |

| Yield (1mil film) | 22.0 | m²/kg | — |

| Flammability | V - 0 | — | ASTM UL-94 |

| Water Absorption (24 hrs) | max. 0.01 | % | — |

| Value | Units | Test Method / Conditions | |

| Melt Point | 240.0 | °C | ASTM D-3418 |

| Continuous Service Temp (Acrylic Adhesive) | 150.0 | °C | — |

| Continuous Service Temp (Silicone Adhesive) | 164.0 | °C | — |

| Heat Sealing Temp | 245 - 260 | °C | — |

| Degradation Temp (Acrylic Adhesive) | 164.0 | °C | — |

| Degradation Temp (Silicone Adhesive) | 178.0 | °C | — |

| Value | Units | Test Method / Conditions | |

| Dielectric Strength (1 mil) | 216.0 | kV/mm | ASTM D-149 |

| Dielectric Constant (1kHz) | 2.55 - 2.63 | — | ASTM D-150 |

| Dissipation Factor (1kHz) | max. 0.005 | — | ASTM D-150 |

| Value | Units | Test Method / Conditions | |

| End Use | -20 - 200 | °F | — |

| Application | 50 - 120 | °F | — |

| Value | Units | Test Method / Conditions | |

| Haze | 0.2 | % | — |

| Optical Clarity | 98.0 | % | — |

| Peel (Stainless Steel (30 minutes)) | 3.5 | lb/inch | — |

| Peel (Glass) | 3.6 | lb/inch | — |

| Peel (Polycarbonate) | 3.7 | lb/inch | — |

| Peel (Acrylic) | 4.3 | lb/inch | — |

| Quick Tack (on Stainless Steel) | 3.8 | lb/sq. | — |

| Thickness | 1.7 | mils | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Information

Adhesive Construction

Adhesive Liner 2mil 2mil Transparent Acrylic 5.5-mil Moisture Stable Polyethylene Coated Kraft release

4mil 4mil Transparent Acrylic 5.5-mil Moisture Stable Polyethylene Coated Kraft release

Adhesive Performance

180° Peel, 2mil P.E.T./ss: 20 min. bond 350°F Shear, 1” x 1” x 1,000 gr., 2mil P.E.T./ss: 20 min bond

2mil 46 oz./inch >24 hrs. 4mil 72 oz./inch >24 hrs. Expanded Copper Foil

Metal = Cu (Copper)

Original Metal Thickness = 2 (0.002”)

2 Cu 4.5 - 75 Strand Width: 4.5 = 0.0045”

Long Way of Diamond: 75 = 0.075”

- System Lay-up

Packaging & Availability

- Availability

- LS-1000® – is available standard with 3 mil FluoroGrip®-E, .004” expanded copper foil, and a new acrylic based pressure sensitive adhesive system developed for applications on supersonic aircraft.

- Available Thicknesses (Film Only; Not Including Adhesive) - 2 mil, 5 mil, 10 mil.

Ordering Information

LS 1000 comes as tapes 1” to 6” or peel and stick applique 6” to 24” (larger widths may be available via custom order).

Form Width Tapes 1” to 6” Applique Film 6” to 24” (larger widths can be custom ordered)