Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Highlights

- Excellent cleaning in immersion and ultrasonic tanks

- Long life because oils split rapidly to the surface of your cleaner tank where they can be skimmed off

- An excellent choice where one product is used for multiple purposes, such as washing mixed batches of ferrous, aluminum, and copper alloy parts in a single-stage washer

- Will provide one-to two-weeks' indoor rust inhibition on iron and steel, as well as inprocess tarnish resistance on copper and copper alloy parts

- Will remove coolant residues as well as straight oils

- Master STAGES™ CLEAN family of advanced-technology products offer highly effective cleaning and with the same in-process "one-step" method, leave behind an effective, short-term, anticorrosive film.

- Designed for specific metals, desired length of corrosion inhibition, and applications ranging from spray, immersion, ultrasonic parts, and dip tank cleaning, Master STAGES cleaners+RP inhibitors are all highly concentrated and economical, most with low foam and very low V.O.C. content.

- Additional Information

- Industrial Use Only

- Consult Master Fluid Solutions before using on any metals or applications not specifically recommended.

- This product should not be mixed with other metalworking fluids or metalworking fluid additives, except as recommended by Master Fluid Solutions, as this may reduce overall performance, result in adverse health effects, or damage the machine tool and parts. If contamination occurs, please contact Master Fluid Solutions for recommended action.

- Master STAGES™ is a trademark of Master Chemical Corporation d/b/a Master Fluid Solutions.

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Use Level

- 3.0 - 10.0 %

- Application Guidelines

- CLEAN 2030 will remove coolant residues at room temperature up to 160°F (71.1°C) in soak, agitated, or ultrasonic tanks. Concentrations in the range of 3% - 5% are effective.

- To remove straight oils, use an agitated or ultrasonic tank and hold concentration from 5% - 10%, adjusting temperature up to 160°F (71.1°C) as needed to get proper cleaning. Do not use CLEAN 2030 above 160°F (71.1°C) in ultrasonic washers.

- Straight oils require skimming as they will split rapidly to the surface. CLEAN 2030 can be used with great results removing screw machine oils in low-pressure spray washers such as auger/drumstyle washers, where the oil helps break foam.

- CLEAN 2030 provides corrosion inhibition for ferrous parts in one step. If you have a multi-stage washer, you may choose Master STAGES™ CLEAN 2020 and follow the washing process with a rinse of Master STAGES™ NOCOR® S2 for extended ferrous corrosion inhibition.

- Product Applications

Applications : Corrosion inhibition, immersion tanks, parts washing, and ultrasonic tanks

Soils : Chlorinated oils, coolant residues, oils, and sulfurized oils

Metals : Aluminum, brass, cast iron, copper, copper alloys, ferrous metals, lead, magnesium, steels, and zinc

Industries : Aerospace, automotive, energy, and medical- Mixing Instructions

- Recommended usage concentration in water: 3.0% - 10.0%.

- To help ensure the best possible working solution, add the required amount of concentrate to the required amount of water (never the reverse) and stir until uniformly mixed.

- Recommended Metalworking Concentrations

Design concentration range : 3.0% - 10.0%

Properties

- Physical Form

- Odor

- Mild, detergent (Concentrate)

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Flash Point (Concentrate) | max. 199 | °F | ASTM D92-90 |

| pH (Concentrate as Range) | 11.5 - 12.0 | — | — |

| pH (Typical Operating as Range) | 10.5 - 11.0 | — | — |

| Coolant Refractometer Factor | 3.0 | — | — |

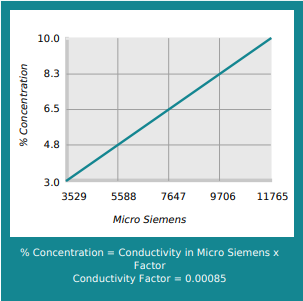

| Cleaner Conductivity Factor | 0.00085 | — | — |

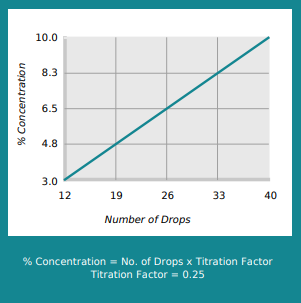

| Titration Factor | 0.25 | — | CL-1 Titration Kit |

| Number of Cleaner Vials | 2.0 | — | CL-1 Titration Kit |

| Cleaner Indicator A or B | A | — | CL-1 Titration Kit |

Regulatory & Compliance

- Product Compliance

CLEAN 2030 is free of borates, nitrites, phenols, phosphate, and SARA 313 listed ingredients.

Technical Details & Test Data

- Test Data

Concentration by Conductivity

Concentration by Titration

Packaging & Availability

- Packaging Type

- Packaging

- 1-gallon jug

- 5-gallon pail

- 54-gallon drum

- 270-gallon tote