Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Industrial Additives Functions

- Polymer Structure

- Gel polystyrene Crosslinked With Divinylbenzene

- Functional Group

- Sulfonic Acid

- Ionic Form

- Na⁺

- Technologies

Features & Benefits

- Industrial Additives Features

- Advantages

- High operating capacity

- Good kinetic performance

- Excellent physical and chemical stability

Applications & Uses

- Markets

- Applicable Processes

- Applications

- Softening - Industrial

- Industrial demineralization when regenerated with acids.

- Systems

- Coflow regenerated systems

- Conventional counterflow systems

Properties

- Appearance

- Spherical Beads

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Total Capacity (Na⁺ Form) | min. 2.0 | eq/L | - |

| Moisture Retention (Na⁺ Form) | 44 - 48 | % | - |

| Particle Size Range | 300 - 1200 | µm | - |

| Particle Size (max. 300µm) | 1.0 | % | - |

| Uniformity Coefficient | max. 1.7 | - | - |

| Reversible Swelling (Na⁺ to H⁺) | 9.0 | % | - |

| Specific Gravity | 1.29 | - | - |

| Temperature Limit | 120.0 | °C | - |

Regulatory & Compliance

- Regulatory Approvals

- IFANCA Halal Certified

- Kosher Certified

- Certified by the WQA to NSF/ANSI-61 Standard

Technical Details & Test Data

- Hydraulic Characteristics

Pressure Drop

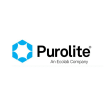

The pressure drop across a bed of ion exchange resin depends on the particle size distribution, bed depth, and voids volume of the exchange material, as well as on the flow rate and viscosity of the influent solution. Factors affecting any of these parameters such as the presence of particulate matter filtered out by the bed, abnormal compressibility of the resin, or the incomplete classification of the bed, will have an adverse effect, and result in an increased head loss. Depending on the quality of the influent water, the application and the design of the plant, service flow rates may vary from 10 to 40 BV/h.

- Hydraulic Characteristics

Backwash

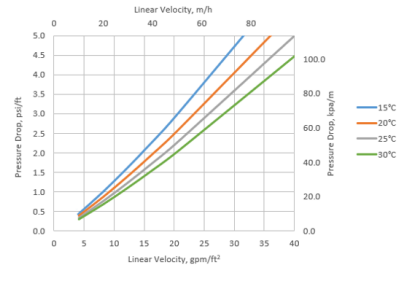

During up-flow backwash, the resin bed should be expanded in volume between 50 and 70% for at least 10 to 15 minutes. This operation will free particulate matter, clear the bed of bubbles and voids, and reclassify the resin particles ensuring minimum resistance to flow. When first putting into service, approximately 30 minutes of expansion is usually sufficient to properly classify the bed. It is important to note that bed expansion increases with flow rate and decreases with influent fluid temperature. Caution must be taken to avoid loss of resin through the top of the vessel by over expansion of the bed.

Packaging & Availability

- Packaging Type

- Packaging

- 1ft³ Sack

- 25L Sack

- 5ft³ Drum (Fiber)

- 1m³ Supersack

- 42ft³ Supersack

- Bulk Tanker (North America only)

Storage & Handling

- Shipping

Shipped in quantity 800 - 840 g/L.