Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Applications

- Coating Type

- Use Level

- 8 - 12 phr

- Product Applications

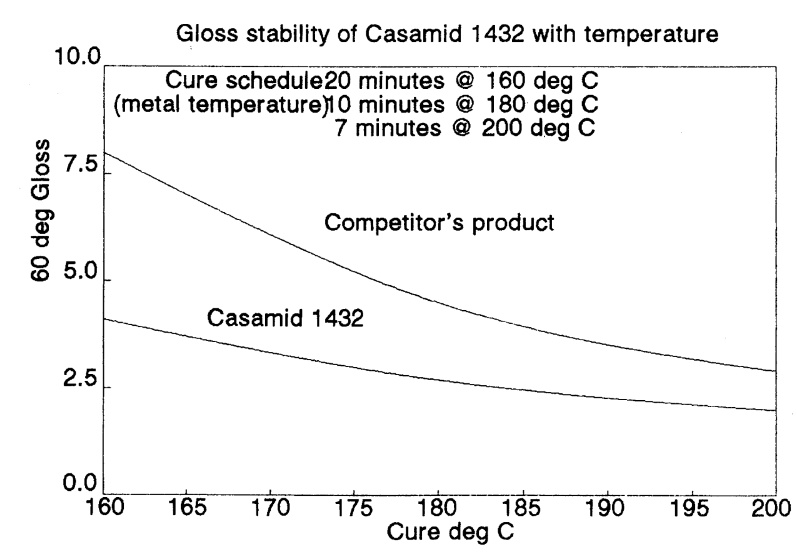

Casamid™ 1432 is intended primarily for use in ultra low gloss powder coatings based on pure epoxy or epoxy modified with hydroxyl terminated polyester. By appropriate formulation, coatings with gloss levels below 5% & impact resistance of 150 - 160 inch pounds may easily be obtained. Casamid™ 1432 may also be used to reduce gloss of hybrid coatings where the polyester content of the binder is <20%.

Typical cure schedules for epoxy coatings cured with CASAMID 1432 are:

- 20 minutes at 160°C

- 10 minutes at180°C At metal temperature

- 7 minutes at 200°C

Casamid™ 1432 is not recommended for use in light colored coatings or in combination with other curing agents or catalysts. Additional information on the use of Casamid™ 1432 may be found in the formulation guidelines included in this booklet.

Properties

- Color

- Physical Form

- Appearance

- Free flowing white powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Sieve Analysis (Passing through 53 µm) | min. 95 | % | - |

| Specific Gravity | 0.89 | - | - |

Packaging & Availability

- Packaging Type

- Packaging Information

Available in 25 kg nett weight, non returnable polyethylene kegs.

Storage & Handling

- Shelf Life

- 12 months

- Shelf Life & Handling

Store under cool, dry conditions. It is recommended that the material be used within 12 months of certification.

Avoid contact with skin and eyes and wear appropriate dust mask. Further details may be obtained from the relevant Health & Safety Data Sheet.