Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Benefits

- Up to 95% recyclable

- Permanent seal

- Reduce water and sealant consumption

- Reduce waste water treatment costs

- Best-in-class chemical and temperature resistance

- Ultimate process stability

- Improve uptime and productivity

- Enhanced washing characteristics

- Environmentally friendly formulation

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

Properties

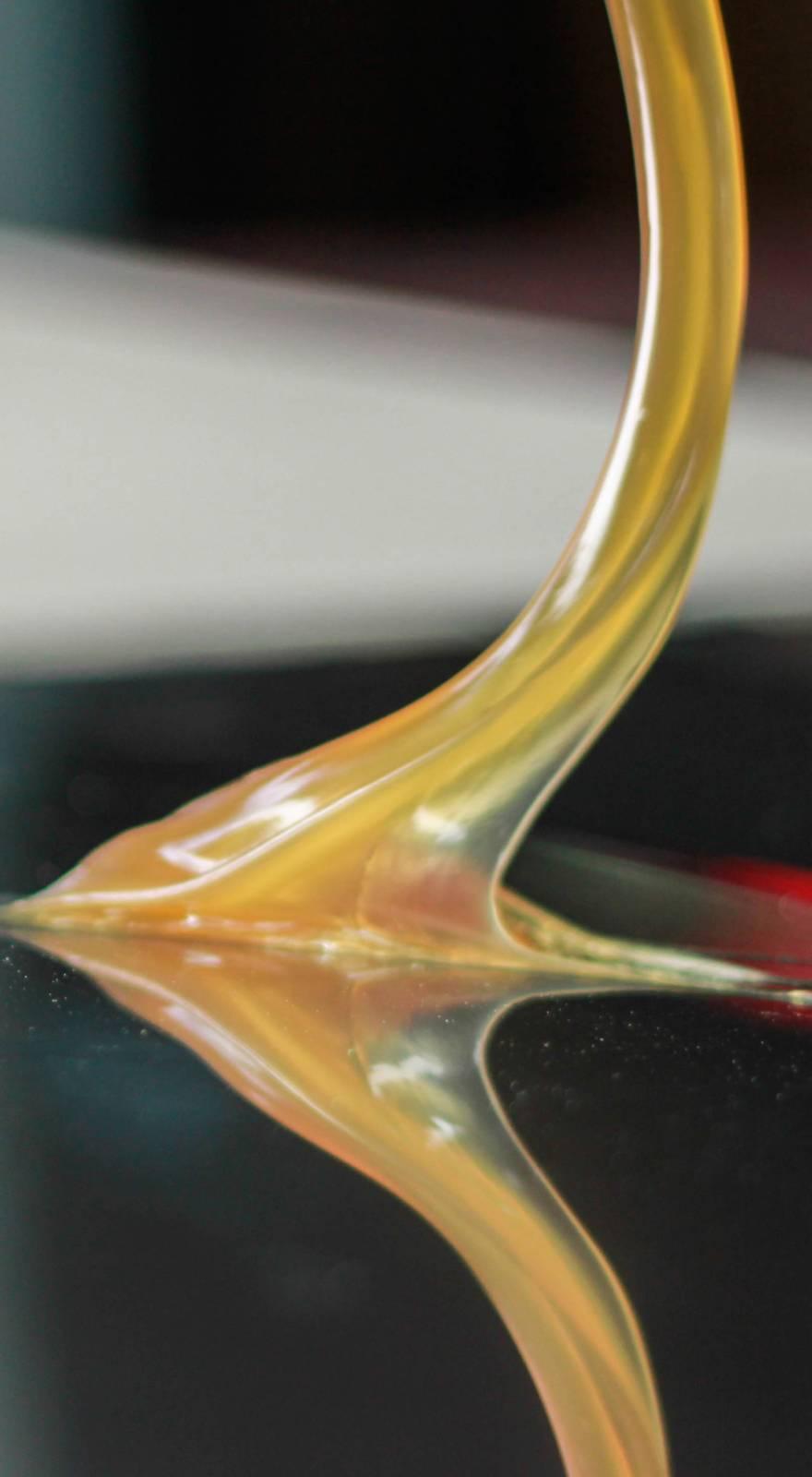

- Appearance

- Clear Plae Straw Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (20°C, Seta Zahn No 1) | 26 - 30 | s | — |

| Flash Point | min. 100 | °C | — |

| Contamination Tolerance | Very Good | — | — |

| Temperature Range (Cured Phase) | -76 to 226 | °C | — |

| Odour | Mild Methacrylate | — | — |

| Specific Gravity (20°C) | 0.910 - 0.935 | — | — |

| Gel Time (0.8%, DB42, Degassed) | 90 - 180 | s | — |

| Washability | Very Good | — | — |

Regulatory & Compliance

- Quality Standards

- Regulatory and Compliance

Rexeal 100 has gained approvals from major automotive OEMs and many of their suppliers and has Qualified Product status for the internationally recognized US Military Specification MIL-I-17563C.

Technical Details & Test Data

- Chemical Resistance

US MIL--17563C Test Conditions, Impregnated US MIL Test Rings, Test Pressure 50 psi

Environment Time Temperature Result Water 14 Days 100°C No Leak Oil 14 Days 99°C No Leak Hydrocarbon Fluid 14 Days 23°C No Leak Carbon Removal Fluid 30 Minutes 23°C No Leak Lubricating Oil 48 Hours 121°C No Leak Turbine Fuel 48 Hours 23°C No Leak Ethylene Glycol 14 Days 149°C No Leak Hydraulic Fluid 14 Days 99°C No Leak Fuel 48 Hours 23°C No Leak Diester Grease 48 Hours 23°C No Leak Sulphuric Acid (18%) 2 Hours 23°C No Leak Stoddard Solvent 48 Hours 23°C No Leak Ethyl Alcohol 14 Days 23°C No Leak

Storage & Handling

- Shelf Life

- 6 Months (Single Pack), 12 Months (Twin Pack)