Knowde Enhanced TDS

Identification & Functionality

- INCI Name

- Cosmetic Ingredients Functions

- Technologies

- Product Families

- Composition

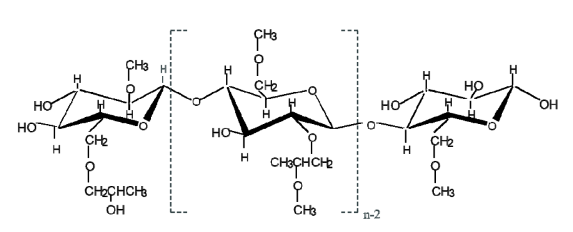

Methoxy and hydroxypropyl substituted cellulosic polymers

- Chemical Structure

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Highlights

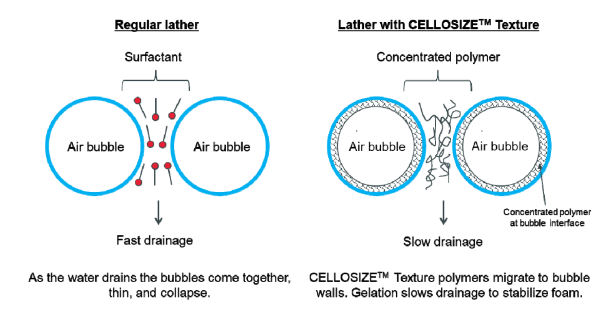

- Foam & lather stabilization

- Thickening

- Lubricity

- Cold water dispersible

- Allows clear formulas

- Mild for the skin

- Stable over a broad pH range (3-11)

- Good salt & electrolyte tolerance

- Synergistic conditioning behavior with UCARE(TM) & SoftCAT(TM) conditioning polymers

Applications & Uses

- Markets

- Applications

- Bath & Shower Applications

- Hair Care Applications

- Personal Hygiene Applications

- Skin Care Applications

- Formulating Tips

Although CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose is soluble in water, it must first be thoroughly dispersed in water to prevent lumping. In some applications, dispersion can be accomplished at ambient temperatures or in cold water by using an educator funnel or high-shear mixer. However, if the powder is added directly to cold water without sufficient agitation, a lumpy solution will result. Lumping results from incomplete wetting of the individual powder particles. Only part of the powder dissolves, leading to the formation of a gelatinous membrane which shields the remaining powder from complete hydration. Several dispersion techniques commonly used are described below.

Dispersion in Hot Water

Often called the “hot/cold” technique, this method takes advantage of the insolubility of CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose in hot water. Heat 1/5 to 1/3 of the total required volume of water to above 90°C, and then add the powder with agitation. Continue mixing until all powder particles are thoroughly wetted.

For complete solubilization, the remainder of the water is then added as cold water or ice to lower the temperature of the dispersion. Once the dispersion reaches the temperature where the powder becomes soluble, the powder begins to hydrate and solution viscosity increases. In general, CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose must be cooled to 20–25°C to achieve complete hydration. Continue mixing for at least 30 minutes after reaching 20–25°C.

In some applications it may be desirable to heat the entire volume of water, disperse the powder, then cool the mixture while agitating until hydration is complete. It is very important, however, to have adequate cooling after wetting with hot water to ensure complete hydration and viscosity development.

Dispersion by Dry Blending

Dry blending involves mixing CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose with other dry ingredients before adding the water component. Dry blending separates the particles of CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose to allow thorough wet-out and complete hydration when water is added.

Begin by blending CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose with other dry powder ingredients. The suggested ratio of other dry powdered ingredients to CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose is 7:1. However, this ratio may vary from 7:1 to 3:1. After blending, add the dry mix to the water with agitation. The rate of hydration will depend upon both the relative particle sizes and the rate of agitation during and after addition of the mixture to water. Continue agitation until the CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose has completely hydrated and the solution is consistently smooth.

Dispersion in Non-solvent Media

CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose may also be dispersed in non- solvent media such as vegetable oil, propylene glycol, polyethylene glycol, glycerine, corn syrup, and high fructose corn syrup. Begin by adding CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose to the non-solvent. A ratio of 5 to 8 parts of non-solvent to 1 part CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose is recommended to obtain a fluid slurry. Agitate the mixture until the particles of CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose are evenly dispersed. The dispersion of CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose in a non-solvent can then be added to cold water, or cold water can be added to the dispersion. Continue mixing until the CELLOSIZE(TM) Texture E50 Hydroxypropyl Methylcellulose powder is completely hydrated and the solution is smooth.

- Limitations

This product is neither tested nor represented as suitable for medical or pharmaceutical uses.

Properties

- Appearance

- Opalescence and Solution color

- Typical Properties

- Microbiological Values

| Value | Units | Test Method / Conditions | |

| Apparent Viscosity (2% in water, at 20°C) | 40 - 60 | mPa.s | Current USP/EP/JP |

| Loss on Drying | max. 5.0 | % | Current USP/EP/JP |

| Residue on Ignition | max. 1.5 | % | Current USP/JP |

| Sulfated Ash Content | max. 1.5 | % | Current EP |

| pH Value (2% in Water) | 5.0 - 8.0 | — | Current USP/EP/JP |

| Assay (Methoxyl) | 28.0 - 30.0 | % | Current USP/EP/JP |

| Assay (Hydroxypropoxyl) | 7.0 - 12.0 | % | Current USP/EP/JP |

| Heavy Metals (as Pb) | max. 20 | ppm | Current USP/EP/JP |

| Bio-based Carbon | 69 | — | % |

| Value | Units | Test Method / Conditions | |

| Total Aerobic Count | max. 100 | cnt/g | Current USP |

| Total Yeast & Mold Count | max. 100 | cnt/g | Current USP |

| Staphylococcus Aureus | Negative | — | Current USP |

| Pseudomonas Aeruginosa | Negative | — | Current USP |

| Salmonella Species | Negative | — | Current USP |

| Escherichia Coli | Negative | — | Current USP |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Mechanism of Action

CELLOSIZE(TM) Texture products offer a unique property called interfacial gelation. This property is the cumulative result of the inherent surface activity and gelling behavior of hydroxypropyl methylcellulose. Interfacial thermal gelation occurs spontaneously even in very dilute systems over a wide range of use temperatures. This formation of gelled films within the foam accounts for the polymer's ability to enhance lather in cleansing products of all types. It also explains why foams are denser and more stable.

Packaging & Availability

- Packaging Type

- Packaging Information

Product is sold in 50 lb bags.

Storage & Handling

- Usable Life and Storage

Shelf life is 36 months. Store the product indoors in a closed container.