Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CAS No.

- 77-85-0

- EC No.

- 201-063-9

- Technologies

- Product Families

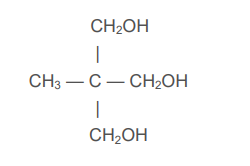

- Structural Formula

Applications & Uses

- Applications

- Coating Type

- Applications

TRIMET® TME is widely used as a raw material for the synthesis of alkyd and polyester resins. The stable neo-pentyl structure, combined with the three primary hydroxyl groups, make TME the ideal choice for preparing resins with very good resistance to heat, moisture and UV light. In waterborne resins, TME helps improve the hydrolytic stability of the resin. Oil-free polyester baking enamels based on TME are noted for their excellent color retention properties and over-bake resistance. TME is commonly used in the preparation of silicone modified polyesters and alkyds designed for high temperature applications such as bakeware, grill and muffler coatings. TME esters may be used as the lubricant base stocks. Depending on the acid chain length, structure and composition, TME esters can be used in lubricants for textile processing or jet engines for example. A list of TME esters along with properties is available upon request. TME is used for pigment surface treatment to improve wetting an dispersing of pigments in extruded plastics, paints and coatings. TME is easily dissolved into water for easy application. TME can also be used as a thermal energy storage material (Phase Change Material) due to its ability to store a large amount of energy in the form of latent heat as it undergoes a phase change. TME has two phase change temperatures depending on its form. Technical Grade TME undergoes a solid/solid phase change at ~ 80°C with a latent heat capacity of ~192 KJ/KG. In the hydrated form it undergoes a solid/liquid phase change at 27-29°C with a latent heat capacity of ~218 KJ/KG. TME is also used in investment casting wax as a filler to reduce thermal expansion and mold cracking. The combination of high melt point, specific gravity, low coefficient of thermal expansion and non-hazardous classification make it an ideal substitute for Bis-phenol A. TME can be used in both watersoluble and paraffinic blends. For additional information on the uses of TME in various applications, please refer to “A Complete Guide to TRIMET® Brand of Trimethylolethane” which can be obtained through your local GEO Specialty Chemicals sales representative.

Properties

- Appearance

- White Crystalline Solid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Melting point | 185 - 195 (199 - 203) | °C | — |

| Density briquettes | 47.1 | lbs / ft3 | — |

| Density granular | 46.4 (48.6) | lbs / ft3 | — |

| Combining weight | 41 (40.5) | — | — |

| Specific gravity | 1.22 | g / ml | — |

| Combining Weight theory | 40.05 | — | — |

| Molecular Weight | 120.15 | — | — |

| Thermal conductivity | 0.17 | W/mK | — |

| Flammability | no | — | — |

| Coefficient of thermal expansion (at max. operating temperature) | 3 | % | — |

| Flashpoint Cleveland open cup | 160 | °C | — |

| Hydroxyl content | min. 41.0 (min. 41.75) | wt % | — |

| Ash as NA2O | max. 0.01 | wt % | — |

| Moisture (Karl Fisher) | max. 0.3 | wt % | — |

| Water insoluble | max. 50 | ppm | — |

| Color | max. 250 (max. 100) | APHA | — |

| Solubility Solvent (25°C, Ethanol) | 27.9 | g / 100g | — |

| Solubility Solvent (25°C, Ethanol) | 75.2 | g / 100g | — |

| Solubility Solvent (25°C, Water) | 40 | g / 100g | — |

| Specific Heat Capacity (25°C) | 1.477 | kJ/kg-C | — |

| Specific Heat Capacity (50°C) | 1.557 | kJ/kg-C | — |

Safety & Health

- Toxicity

TME is essentially non-toxic. The LD50 in mice is greater than 5000mg / kg. TME is mildly irritating to abraded skin with a score of 0.6 in the Draize test. TME is not irritating to the eye with a score of 0.0 in the Draize test. No toxicological or allergenic problems have been noted during our many years of production experience.

Storage & Handling

- Handling & Storage

Handling & Storage: TRIMET® TME is packaged in 50lb and 25kg multi-wall paper bags with HDPE liners. Super sacks containing 500kg / 1102lb and lined with antistatic LDPE are also available. TME is a combustible solid with a flashpoint (Cleveland open cup) of 160°C. Store in a cool, dry area. Do not store near oxidizers. The moisture content of TRIMET® TME may increase slowly with extended storage.

Shelf life: TRIMET® TME has a minimum shelf life of not less than 3 years if stored in its original unopened container and under normal storage conditions. Granular TRIMET® TME Tech storage should be limited to 6 months or less due to a tendency of the product to cake. To minimize caking, pallets should not be stacked on top of each other and storage temperatures should be minimized. High humidity conditions may accelerate caking especially if packaging has been opened.