Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- Fast at room temperature (about 4 minutes).

- Low shrinkage.

- 100% reactive, non-solvent system.

- Easy mixing ratio of resin and hardener.

- No fuming on gelation.

Applications & Uses

- Markets

- Cure Method

- Typical Applications

- Bonding voice coil to cone.

- Bonding pole piece to magnet.

- Bonding alnico magnet to base.

- Rapid curing structural and electrical repair kit.

- Rapid curing laminates and “gel” coats.

- Potting electronic boards.

- Encapsulating electrical and electronic components.

Properties

- Typical Properties (Uncured)

Property Part A Part B Base Epoxy Amine Appearance Clear Lt Amber Viscosity at 25ºC, cP 10,000 to 16,000 12,000 to 18,000

Mix Ratio by Weight 1 1 Specific Gravity 1.17 1.13 - Cured Speed vs Temperature

Shear Strength on steel lap-shear specimens tested at 22ºC, according to ASTM D1002.

Cure Time Temperature % of Initial Strength

2 hours 22ºC 30 4 hours 22ºC 40 16 hours 22°C 42 24 hours 22°C 100 2 hours 45°C 100 - Typical Cured Performance

Shear Strength on lap-shear specimens tested according to ASTM D1002.

Cure Time at 22ºC Substrate Shear Strength (psi)

24 hours GB Aluminum 1000 - 2000 24 hours GB Steel 2000 - 3000 - Typical Environmental Resistance

Shear Strength on steel lap-shear specimens tested according to ASTM D1002. Cured for 72 hours at 22ºC.

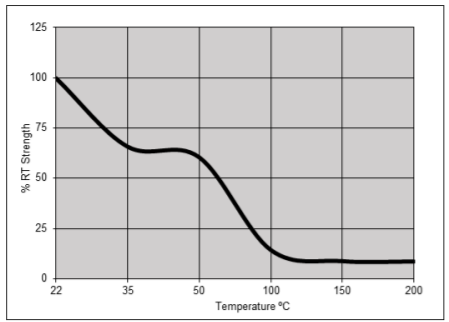

Hot Strength

Tested at temperature

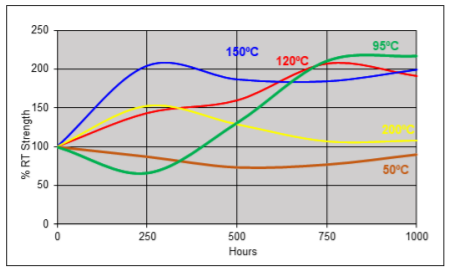

Heat Aging

Aged at the temperature indicated and tested at 22ºC.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- General Information

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials. For safe handling information on this product, consult the Safety Data Sheet (SDS).

Storage & Handling

- Storage

Tuffbond® 305 should be stored in a cool, dry location in unopened containers at a temperature between 45ºF to 85ºF (7ºC to 29ºC) unless otherwise labeled. Optimal storage is at the lower half of this temperature range. To prevent contamination of unused material, do not return any material to its original container.