Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Properties

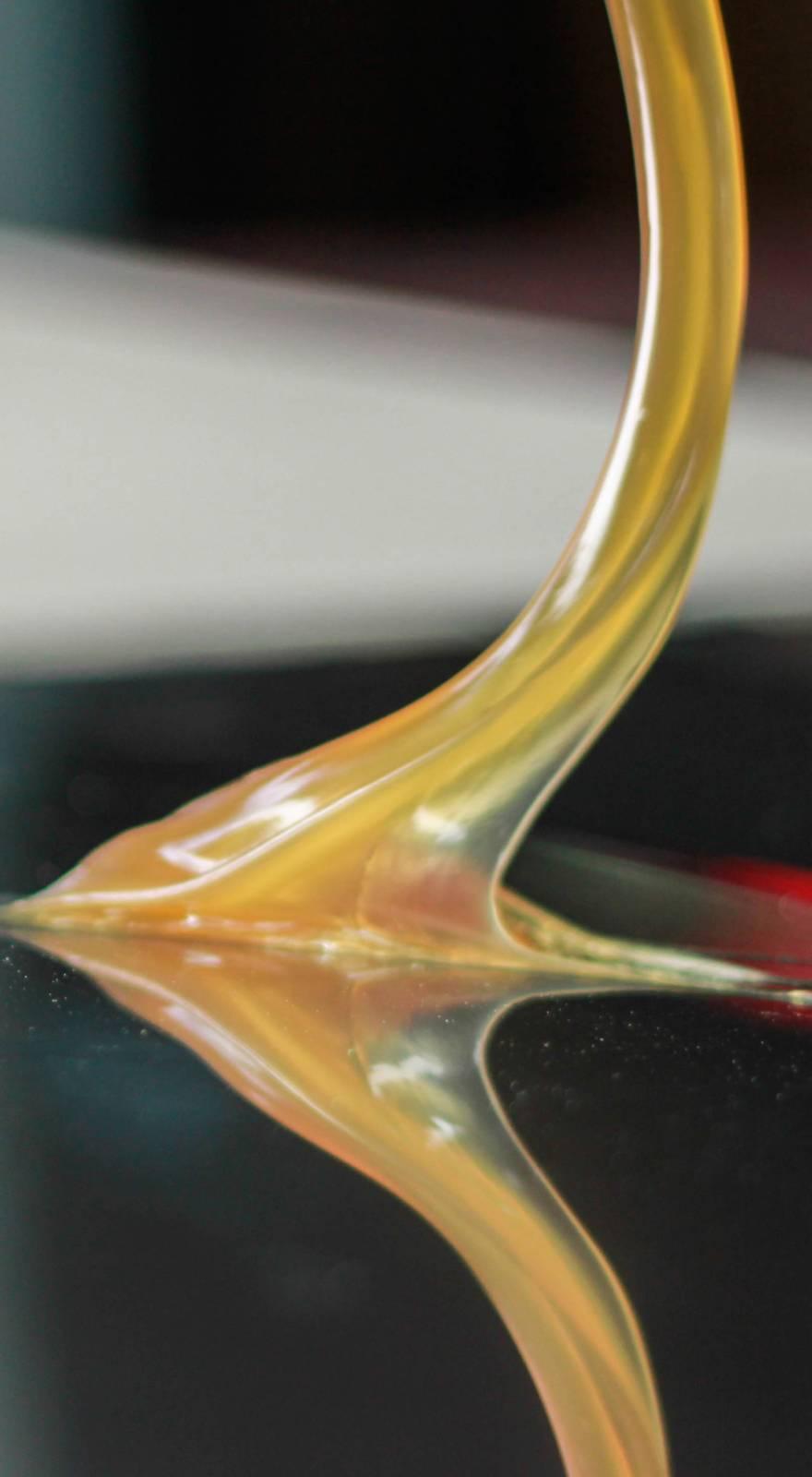

- Appearance

- Amber liquid, Black liquid

- Typical Properties

- Handling Properties

| Value | Units | Test Method / Conditions | |

| Hardness Change (1000 hours, 56ºC) | 3 | Shore A | — |

| Viscosity (25ºC) (Part A) | 2000 | cps | — |

| Hardness Change | -8 | Shore A | — |

| Density (PART A) | 7.5 | lbs./gal | — |

| Hardness (25ºC) | 45 | Shore A | — |

| Hardness (-40ºC) | 65 | Shore A | — |

| Viscosity (25ºC) (Part B) | 30 | cps | — |

| Hardness (85ºC) | 30 | Shore A | — |

| Density (PART B) | 10.3 | lbs./gal | — |

| Tensile Strength (25ºC) | 350 | psi | — |

| Tensile Modulus (-40 ºC at 10% elongation) | 75 | psi | — |

| Tensile Modulus (-40 ºC at 50% elongation) | 260 | psi | — |

| Tensile Elongation (at -40ºC) | min. 50 | % | — |

| Tensile Elongation (at 25ºC) | 400 | % | — |

| Tear Strength (Die C) (PLI) (25 ºC) | 35 | — | — |

| Thermal Conductivity | 3.4 x 10^4 | cal/cm2/cm/ ºC/sec | — |

| Dielectric Constant (100 Hz) (25°C) | 2.34 | — | — |

| Dielectric Constant (100 Hz) (85°C) | 2.51 | — | — |

| Dissipation Factor (100 KHZ) (25ºC) | 0.011 | — | — |

| Dissipation Factor (100 KHZ) (85ºC) | 0.019 | — | — |

| Volume Resistivity (25°C) | 1.3 x 10^14 | ohm-cm | — |

| Volume Resistivity (85°C) | 8.9 x 10^11 | ohm-cm | — |

| Weight Loss (500 hours) (85ºC) | 2.8 | % | — |

| Weight Loss (500 hour) (110ºC) | 4.2 | % | — |

| Weight Change | 0.27 | % | — |

| Value | Units | Test Method / Conditions | |

| Mix Ratio, by weight, (PART A) | 100 | — | — |

| Gel Time (25ºC) (100 g) (PART A) | 45 - 60 | minutes | — |

| Cure Time (at 25ºC) (PART A) | 72 | hours | — |

| Mix Ratio, by weight, (PART B) | 16 | — | — |

| Gel Time (25ºC) (100 g) (PART B) | 45 - 60 | minutes | — |

| Cure Time (at 25ºC) (PART B) | 72 | hours | — |

Technical Details & Test Data

- Chemical Resistance

Chemical Tensile Properties

ChangeHardness Change,

Shore AWeight Change, % Sulfuric Acid, 3% No Change -1 +0.019 Sodium Hydroxide, 0.2 N No Change -1.5 +0.027 Sodium Chloride, 5% No Change No Change +0.062 Sodium Carbonate, 0.1 N No Change -1 +0.073 Acetic Acid, 5% No Change -2 +0.156

Safety & Health

- Safety

LEECAST 23-130-5 Part B is a super cooled liquid and may crystallize. Store at 75–95oF. If crystallization occurs, heat to 120oF in a vented oven. Do not overheat. Avoid skin contact and do not inhale vapors. Always use in a well-ventilated area.

Storage & Handling

- Handling and Mixing

LEECAST 23-130-5 may be mixed and poured at room temperature without de-airing. Air bubbles mixed into the system will rise out of the liquid before gellation. A typical cure cycle is overnight at 25oC plus 2 hours at 80oC or 72 hours at 25oC.

- Shelf life

12 months