- Polymer Name:Polyamide 6 (PA 6)

- Reinforcement Material:Glass Fibers

- Chemical Family:Polyamides

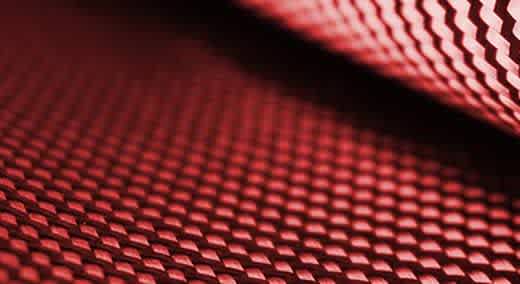

- Processing Methods:Filament Winding, Thermoforming, Continuous Lamination

- End Uses:Robotics

Akulon® K20HG60 is a polyamide 6 (PA 6) that serves as a resin, binder, and matrix material with the additional benefit of a low carbon footprint. Its features include cost-effectiveness, design flexibility, good strength, heat stabilization, high-temperature resistance, and light weight, making it suitable for various markets including automotive, electrical, electronics, and industrial applications.